Electric main shaft tool mechanism for performance testing

A technology of electric spindle and tooling, which is applied in the direction of measuring devices and instruments, can solve the problems that the accuracy and reliability of the test results cannot be guaranteed, the lack of a unified tooling mechanism for the test of the electric spindle, and the low test efficiency, so as to improve the test efficiency. The effect of reducing test cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

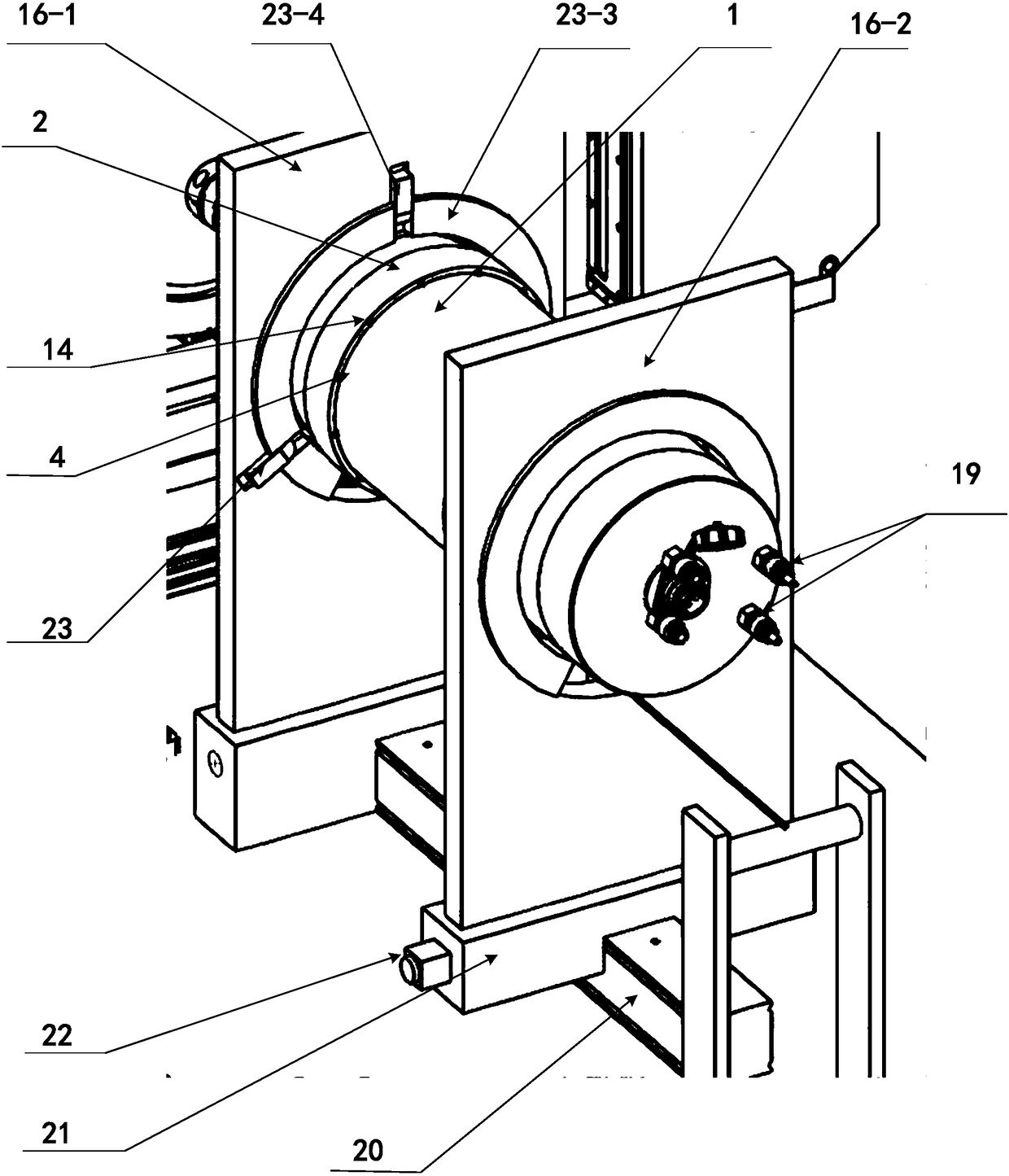

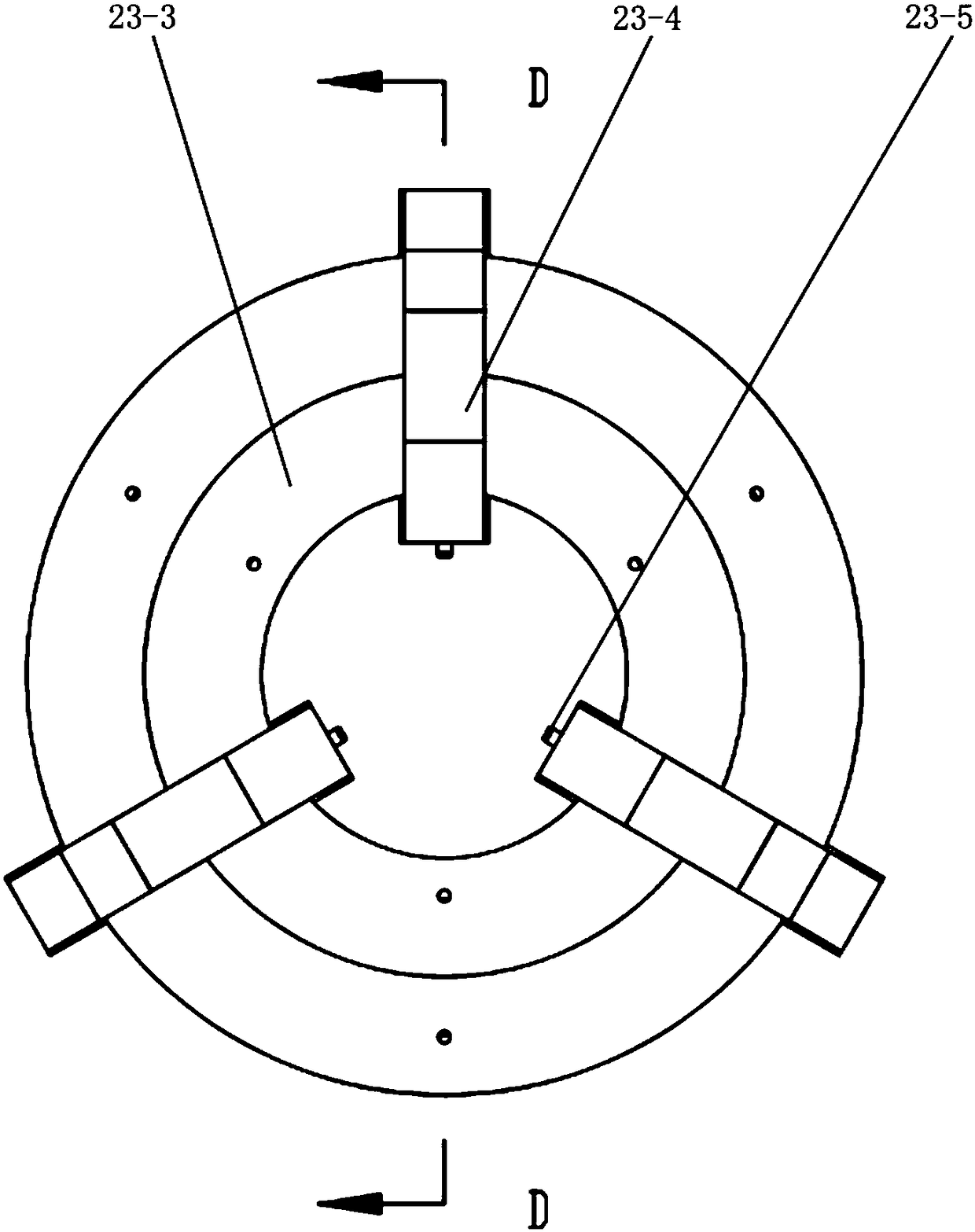

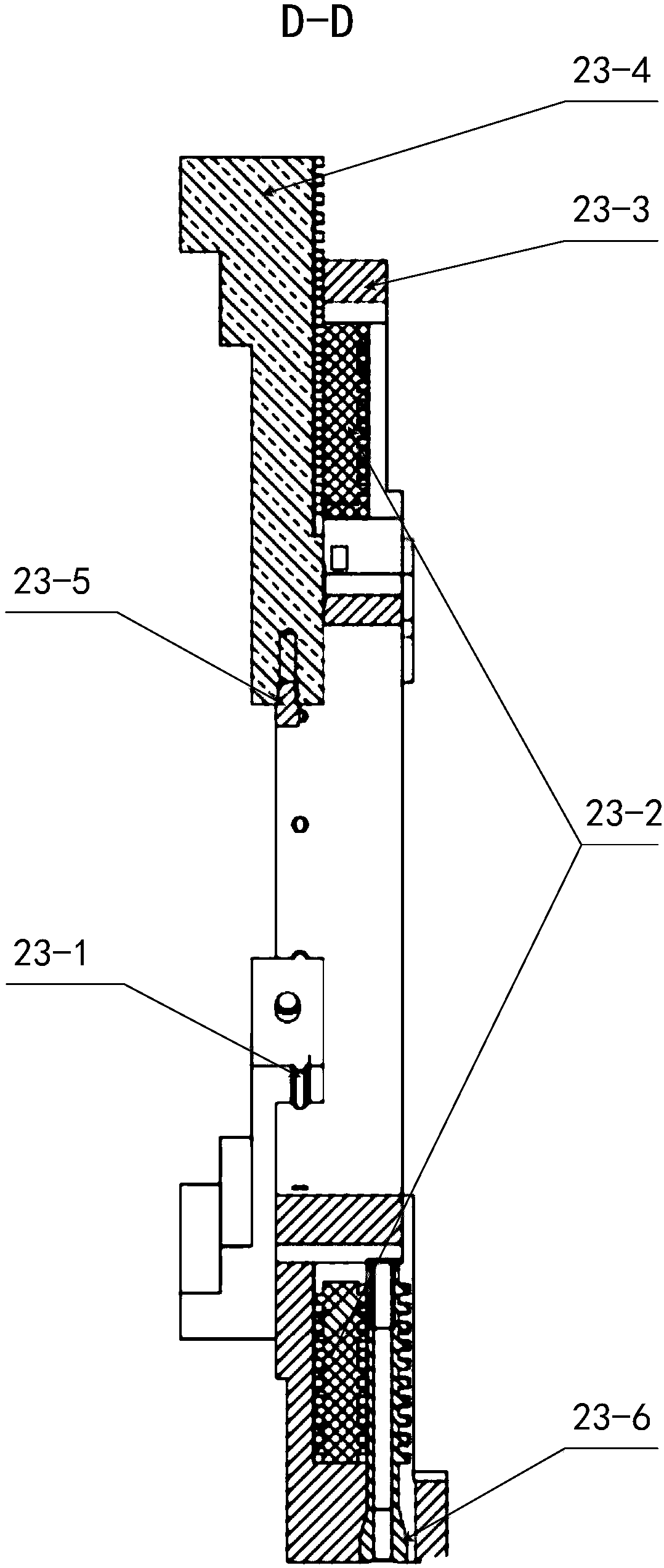

[0024] Such as Figures 1 to 3 As shown, the electric spindle tooling mechanism used for performance testing includes a fixed splint 16-1 and a movable splint 16-2 respectively arranged at both ends of the electric spindle 1 under test, and the movable splint 16-2 adjusts the movable splint 16-2 through the movable splint sliding mechanism. 2 and the distance between the fixed splint 16-1. The movable splint sliding mechanism includes a sliding seat 21 connected to the movable splint 16-2, a linear slide rail 20 slidably connected with the sliding splint 21 and a locking bolt 22 for locking the sliding seat 21 on the linear sliding rail 20, The sliding seat 21 and the linear slide rail 20 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com