Verticality testing tool

A verticality and tooling technology, applied in measuring devices, electrical devices, instruments, etc., can solve the problems of inaccurate test results, reduced test accuracy, inaccurate test results, etc., to achieve intuitive and reliable results, low manufacturing costs, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

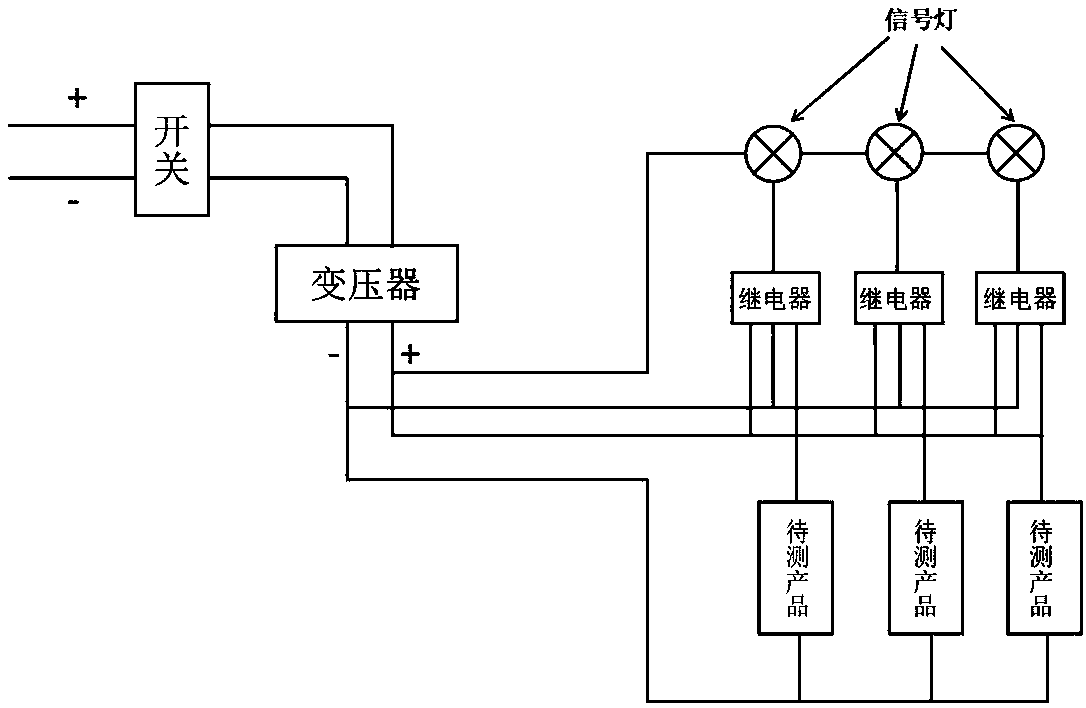

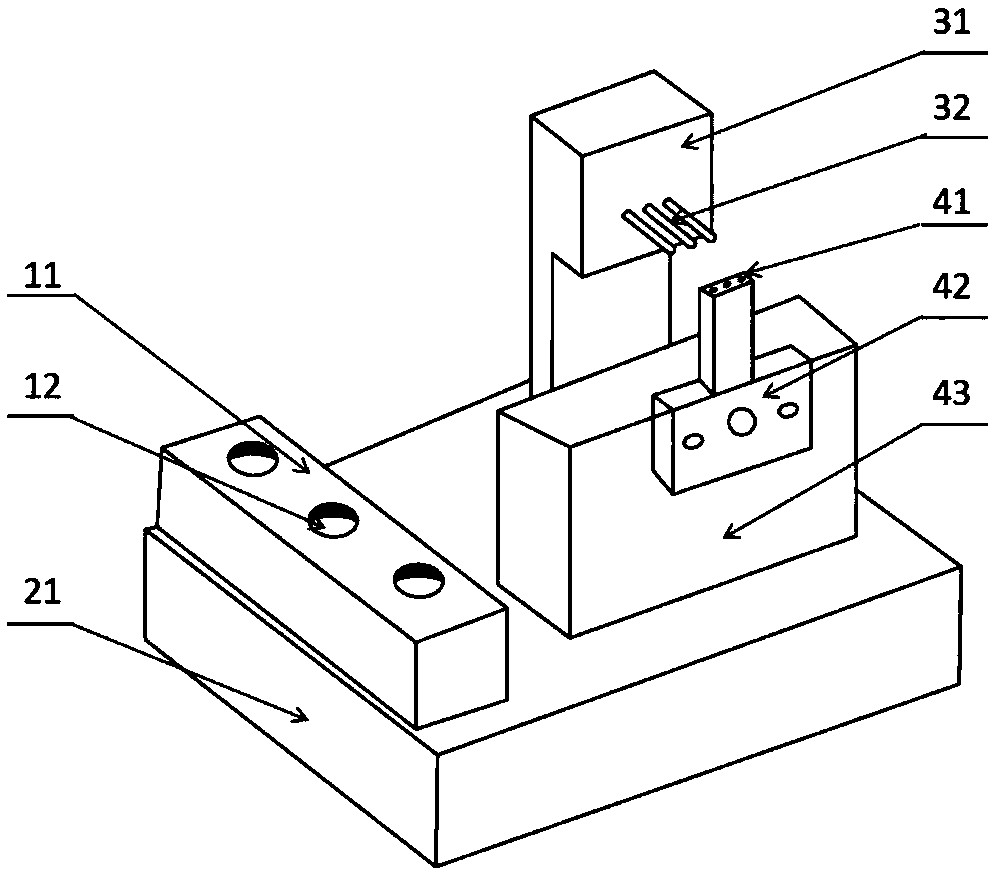

[0045] Such as figure 1 Shown is the schematic diagram of the verticality detection of the embedded metal insert in the injection molded product. Using electrical detection, the external industrial 220V AC power is converted into DC power below 36V through a transformer. During the detection process, workers are not in danger of electric shock; connect the external power supply, turn on the circuit switch, the circuit is turned on, and the signal light is on; place the product to be tested in the The verticality detection tooling equipment, through signal transmission, the verticality tolerance signal of the product to be tested is sent to the relay, and the relay sends a signal to the signal light, and the control signal light is always on or off, and it can be intuitively seen whether the verticality of the product to be tested is Qualified, simple operation, intuitive and reliable test results. For products that only need to detect the verticality of one metal insert, only...

Embodiment 2

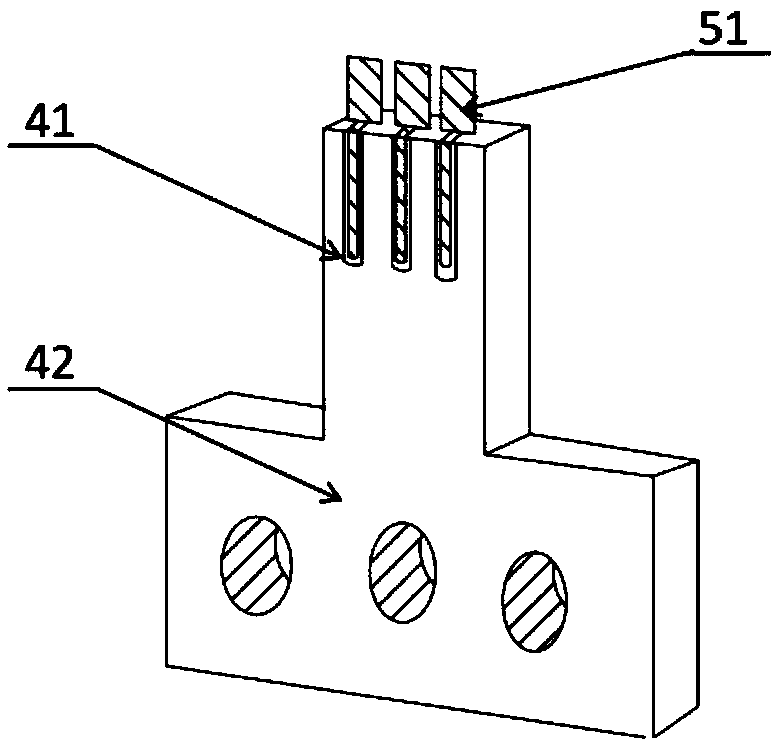

[0057] Figure 4 It is a schematic structural diagram of the verticality detection tooling of the embodiment 2. The overall structure of this embodiment 2 is the same as that of embodiment 1, and the method of use is also the same. The difference is that the verticality detection tool is not provided with a base, but a base 42 is directly arranged on the bottom plate. On the base 42 A vertical slot 41 is provided with the upper end facing downwards. The design of the vertical slot 41 is the same as in Embodiment 1. The base 42 is directly fixed on the upper end surface of the bottom plate 21, eliminating the setting of the base and simplifying the verticality detection. The structure of the tooling. In order to facilitate the taking and placing of the product to be tested, the structure of the base 42 is set in an "L" shape, and the bottom side of the "L" is connected to the bottom plate 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com