Refrigerating equipment

A technology of refrigeration equipment and socket slots, which is applied in the fields of isolation of refrigeration equipment, household refrigeration equipment, lighting and heating equipment, etc., and can solve the problems of complex process, complex structure, and inconvenient sealing treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as Figure 4 As shown, the refrigerator according to an embodiment of the present invention includes: a door body 20 and a box body 24, the front end of the box body 24 is open, the door body 20 is connected with the front end of the box body 24, and after the door body 20 is closed, it is connected to the box body Body 24 forms a storage chamber. The door body 20 includes: a door liner 200, which is adjacent to the storage chamber. The door liner 200 includes: a left door seal 206, which is arranged at the left end of the door liner 200 and integrally formed with the door liner 200. A part of the left door seal 206 is connected with the door liner 200 The left end of the left end forms the left door liner insertion slot 208; the door shell 202 is set opposite to the door liner 200, and after the left end of the door shell 202 is bent, it extends into the left door liner insertion slot 208; symmetrically, the door liner 200 also includes At the right end, there is...

Embodiment 2

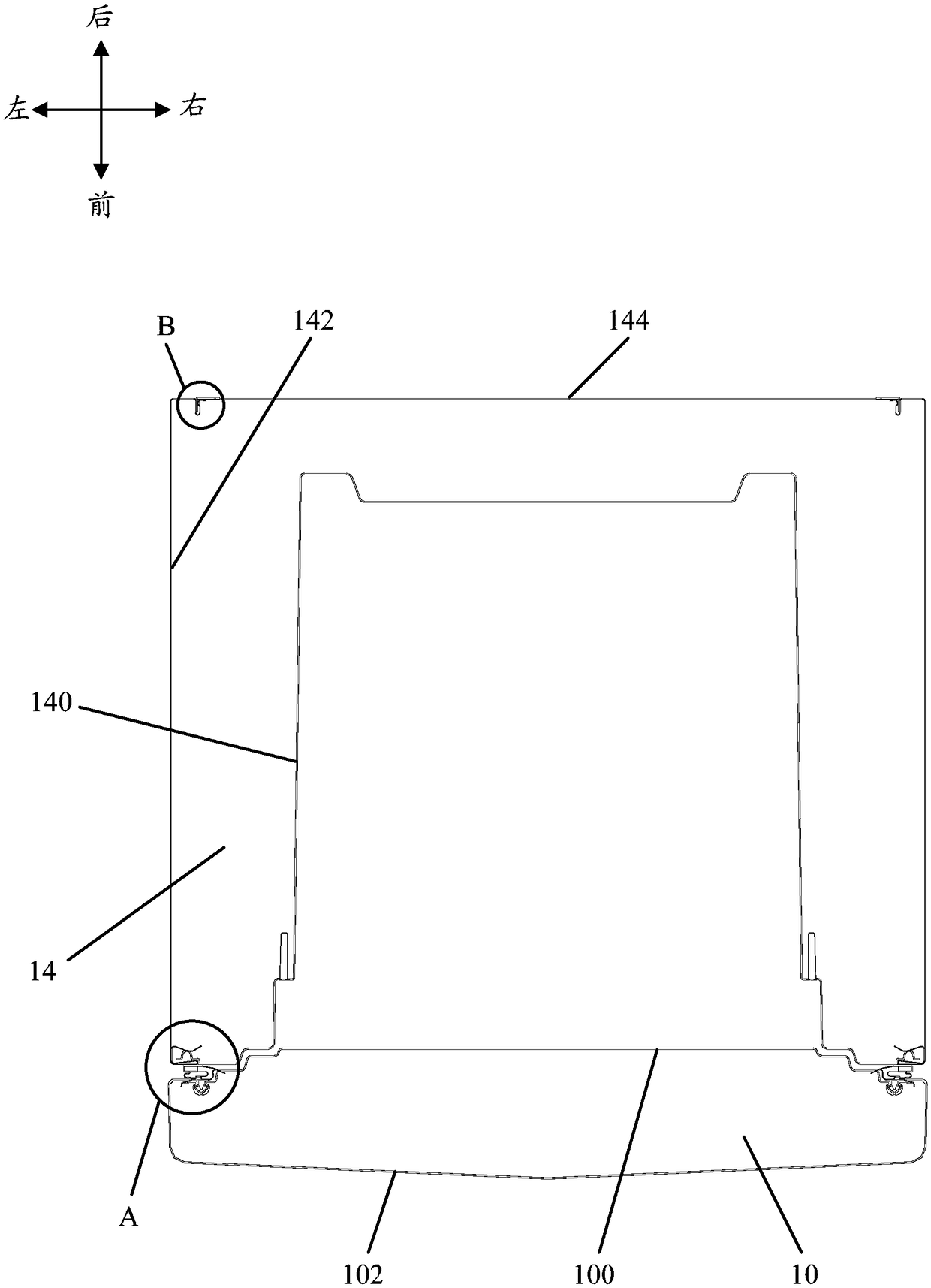

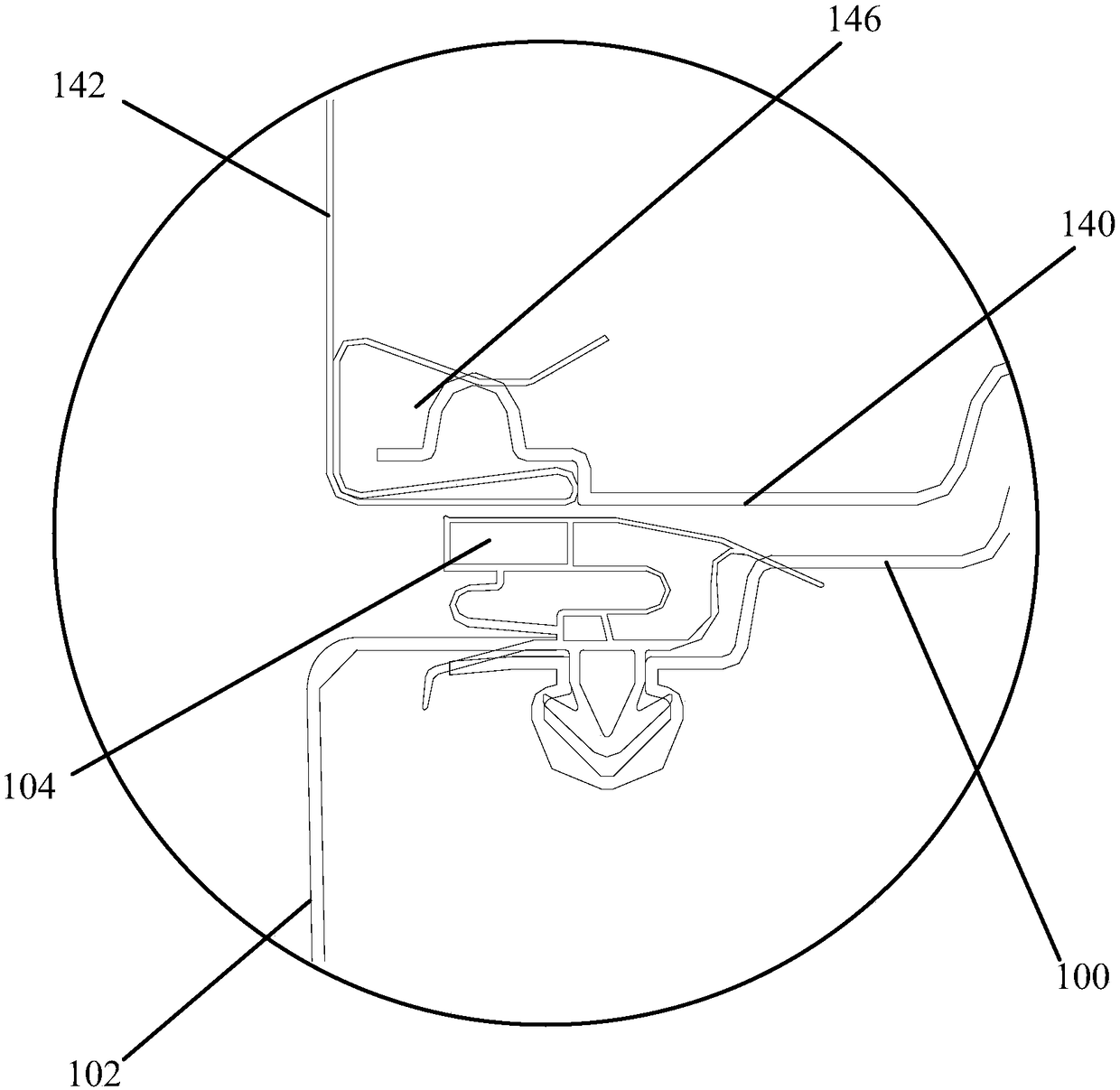

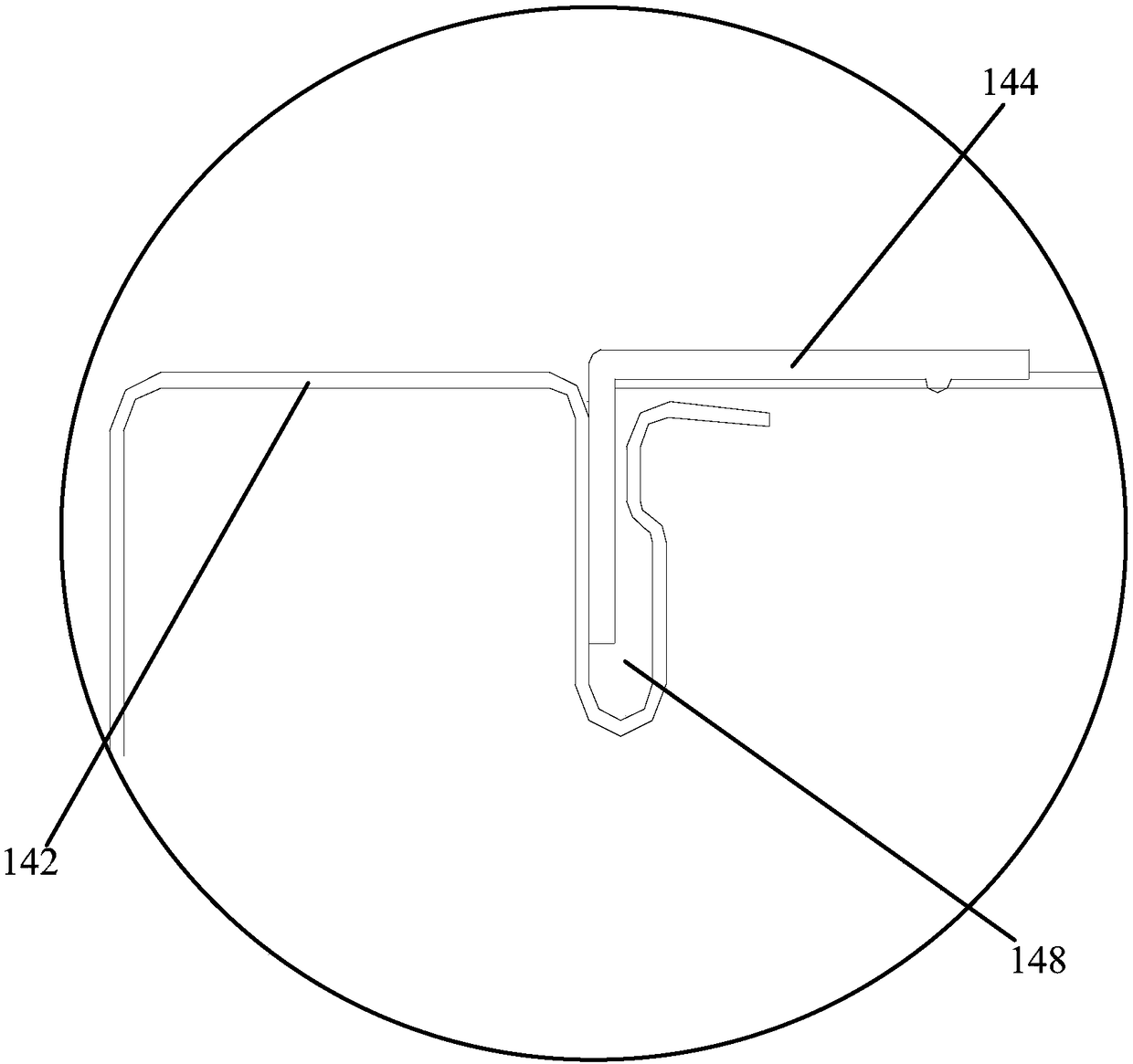

[0049] According to another embodiment of the present invention, the difference from Embodiment 1 is that the left side plate 242, the right side plate 246 are integrally formed with the tank liner 240, that is, in Embodiment 1, the left side plate 242, the right side plate 246 It is connected with the tank liner 240 by plugging, but the plug-in connection is canceled in this embodiment, and the left side plate 242, the right side plate 246 and the tank liner 240 are integrally formed during production.

[0050] The left side plate 242, the right side plate 246 and the tank liner 240 are integrally formed, which can reduce the connection positions, increase the installation speed, and improve the sealing performance of the box cavity 248; the left side plate 242, the right side plate 246 and the back plate 244 still use The plug-in connection facilitates the removal of the back plate 244 for maintenance when a component of the refrigeration equipment fails.

Embodiment 3

[0052]According to another embodiment of the present invention, on the basis of Embodiment 1, the door body cavity 204 and the box body cavity 248 are filled with a polyurethane foam layer, so that the vacuum of the door body cavity 204 or the box body cavity 248 When the state fails, the refrigeration equipment can be thermally insulated through the polyurethane foam layer, which improves the reliability of the refrigeration equipment.

[0053] The technical solution of the present invention has been described in detail above in conjunction with the accompanying drawings. Through the technical solution of the present invention, the connection structure between the door shell and the door liner, the connection structure between the tank liner and the side plate of the box body, and the side plate in the refrigeration equipment have been improved. The connection structure with the backplane improves the sealing performance of each connection structure, so that the door body cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com