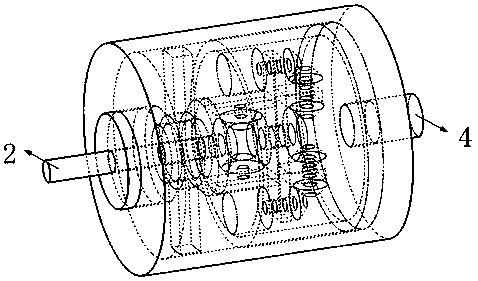

Impact-resistant speed changer based on volute spiral spring

A scroll spring, anti-shock technology, applied in transmission parts, gear vibration/noise attenuation, belt/chain/gear, etc., can solve the problems of gear impact damage, reduce gear service life, gear slipping, etc., and achieve extended use The effect of life, large transmission, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

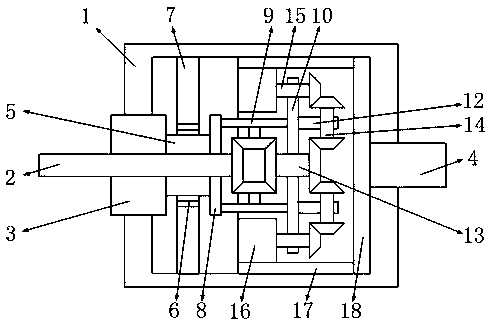

[0067] Specific embodiments: after the drive of the input shaft 2 and the load of the output shaft 4 disappear, the reset of the scroll spring 32 is performed.

[0068] In summary, the main beneficial effect of the present invention is: the beneficial effect of using the spiral spring 32 in the connecting mechanism 3 to realize the variable speed drive in the present invention is: use a simple structure to realize the variable speed effect, and at the same time, because the spiral spring 32 provides The shifting force is continuous, and will not cause physical impact damage at the moment of gear shifting, which greatly prolongs the service life of the transmission; the present invention utilizes the engagement of the driving bevel gear 22 with other bevel gears to make the gear 16 rotate on its own, realizing a relatively fast The transmission of large torque, in addition, under the effect of shifting speed of the connecting structure, the gear 16 revolves around the ring gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com