Special anti-loosening clamping connection lubricating fastener

A fastener and anti-loosening technology, applied in the direction of engine lubrication, fixtures, engine components, etc., can solve the problems of high production and use costs, complex assembly, single function, etc., to achieve convenient assembly, reliable stability, good The effect of anti-loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

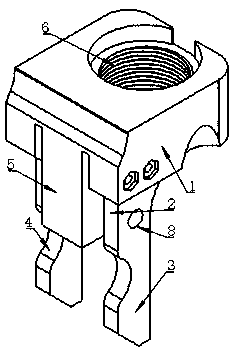

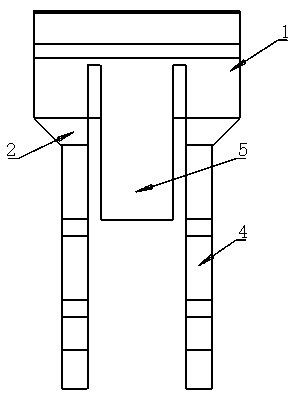

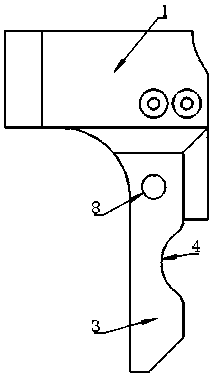

[0018] Such as Figure 1 to Figure 7 As shown in the figure, a special anti-loosening snap-fit connection lubricating fastener is assembled with the mechanical structure through snap-fit assembly, and the snap-fastening anti-loosening groove provided on the structure can make the assembled parts It has a better anti-loosening effect, which makes the overall assembly stability of the parts better, more convenient during assembly, and better connection tightness. By setting the second snap-fit assembly connection column structure on the parts, it can be assembled during assembly. The stability of the fastener is more reliable, so that the safety of the mechanical equipment is higher during use. The fastener is provided with a lubricating fastening connection hole at the upper end, and two sets of parallel distributed helical screws are arranged in the lubricating fastening connection hole. Shaped threaded connection groove, so that it can be better assembled and connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com