A device and method for automatically sealing water in a confined water formation and then grouting it

A technology of automatic water sealing and confined water, which is applied in sealing/isolation, earthwork drilling, drilling pipe, etc. Simple structure, convenient production and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

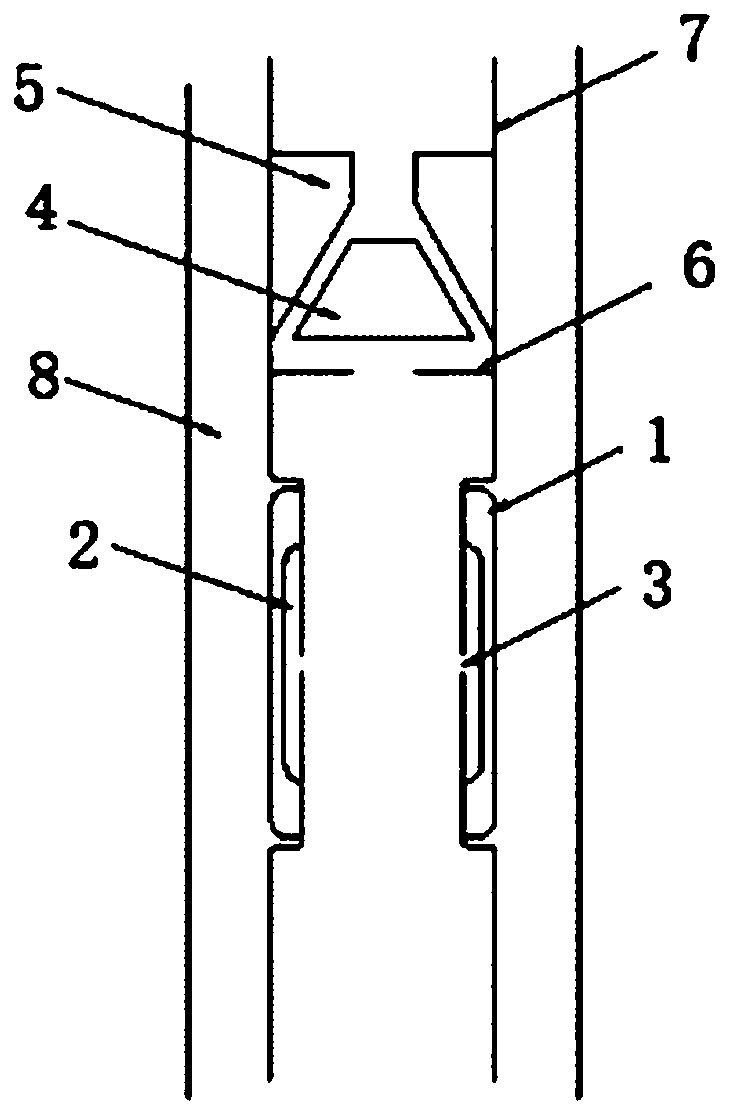

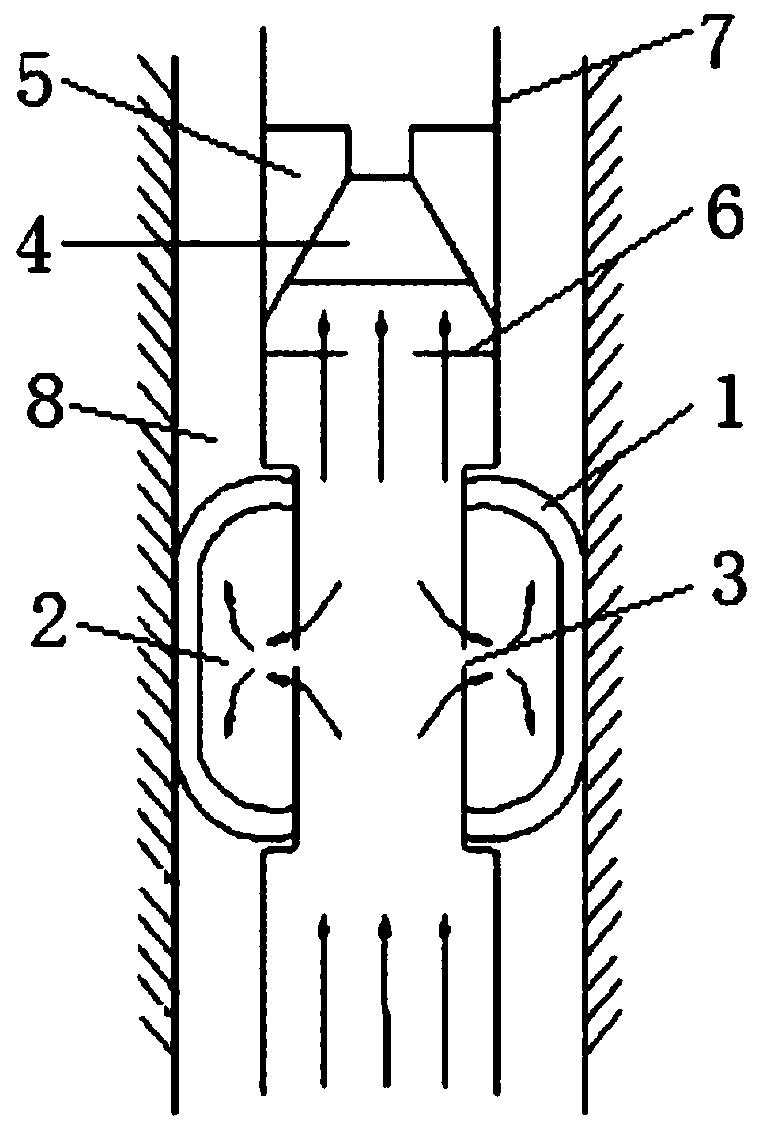

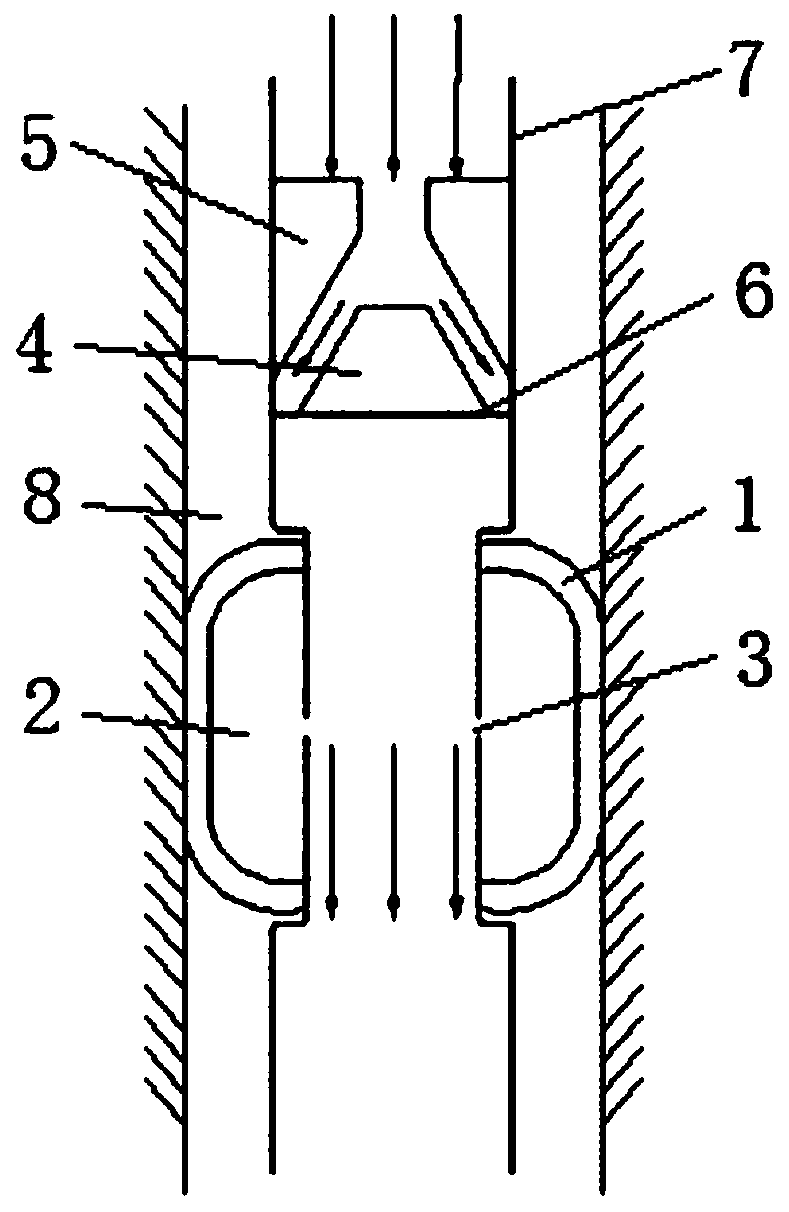

[0028] Such as Figure 1~4 As shown, a device for automatically sealing water in pressurized water formations after grouting, including a drill pipe 7, the inside of the drill pipe 7 is a hollow channel, and the upper part of the hollow channel is provided with a movable sealing structure for automatically opening or sealing the hollow channel The side wall of the middle part of the drill pipe 7 is provided with a circle of drill pipe holes 3 for gushing out of the pressurized water. The outer expanded rubber ring 1 seals all drill pipe holes 3 therein.

[0029] The movable sealing structure includes a baffle 6, a round platform rubber plug 4 and an auxiliary sealing ring 5. The baffle 6 is horizontally arranged and fixed on the inner wall of the drill pipe 7. The baffle 6 is provided with holes for pressurized water to surge up or grouting to move down. , the auxiliary sealing ring 5 is arranged above the baffle plate 6 and fixed on the inner wall of the drill pipe 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com