A water-based uv-type protective coating for stainless steel with excellent cnc resistance

A technology for protecting paint and stainless steel, applied in the direction of polyurea/polyurethane paint, coating, etc., can solve the problem of poor performance, achieve the effect of protecting health, good CNC cutting resistance, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

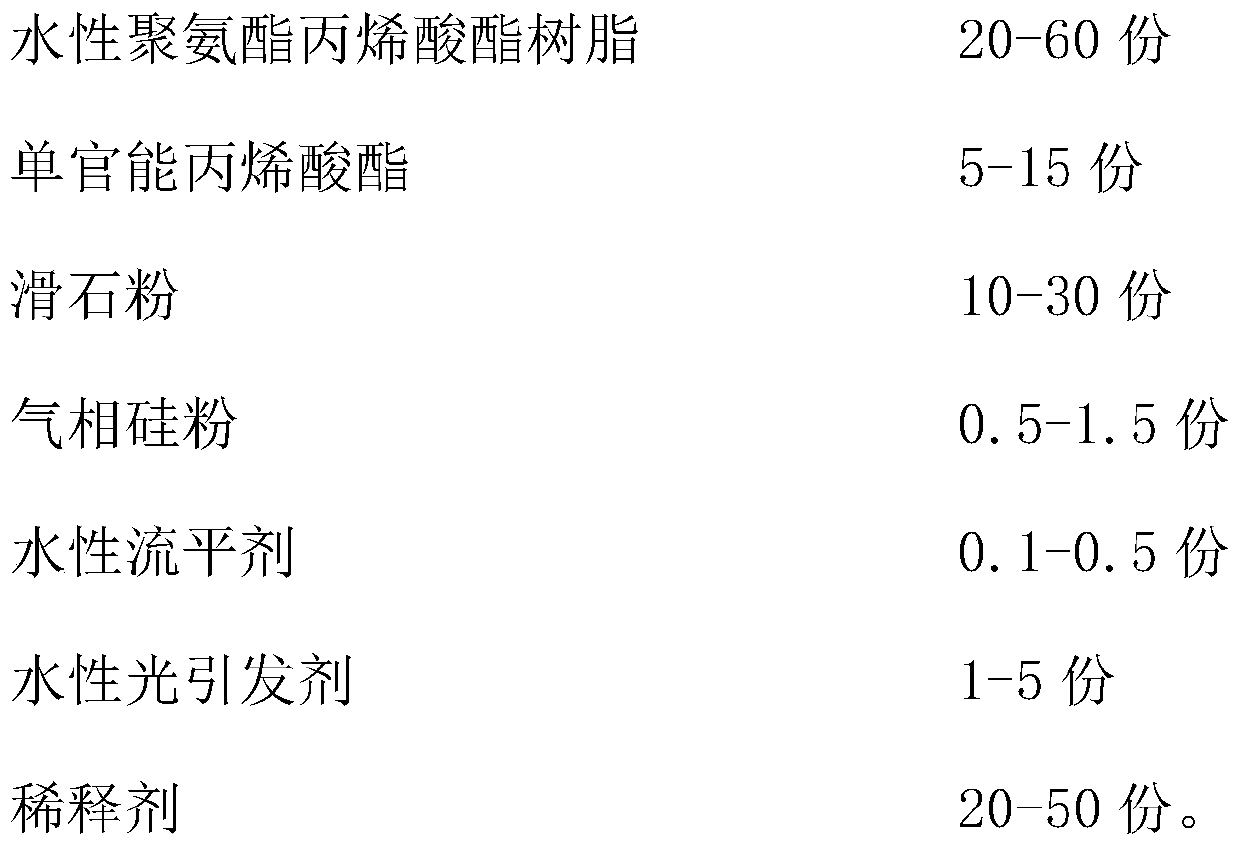

Method used

Image

Examples

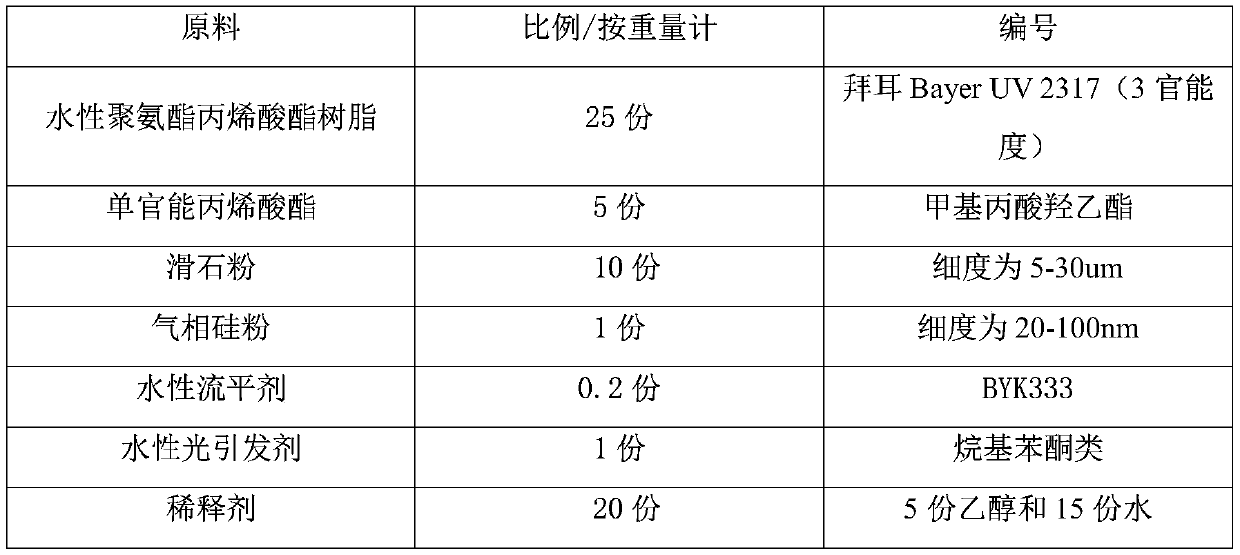

Embodiment 1

[0027]

Embodiment 2

[0029] raw material Ratio / by weight Numbering Waterborne polyurethane acrylate resin 20 copies Bayer series 6 functionality monofunctional acrylate 5 copies Hydroxyethyl Acrylate talcum powder 15 copies The fineness is 5-30um fumed silicon powder 1.5 servings The fineness is 20-100nm Water-based leveling agent 0.1 part BYK333 water-based photoinitiator 2 copies benzils Thinner 30 copies 25 parts ethanol and 15 parts water

Embodiment 3

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com