Hydraulic servo system for bridge accurate closure

A hydraulic servo system and precise technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of affecting the construction period, high difficulty and high construction cost, to protect the safety of the structure, reduce the vibration of the structure, and reduce the construction cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

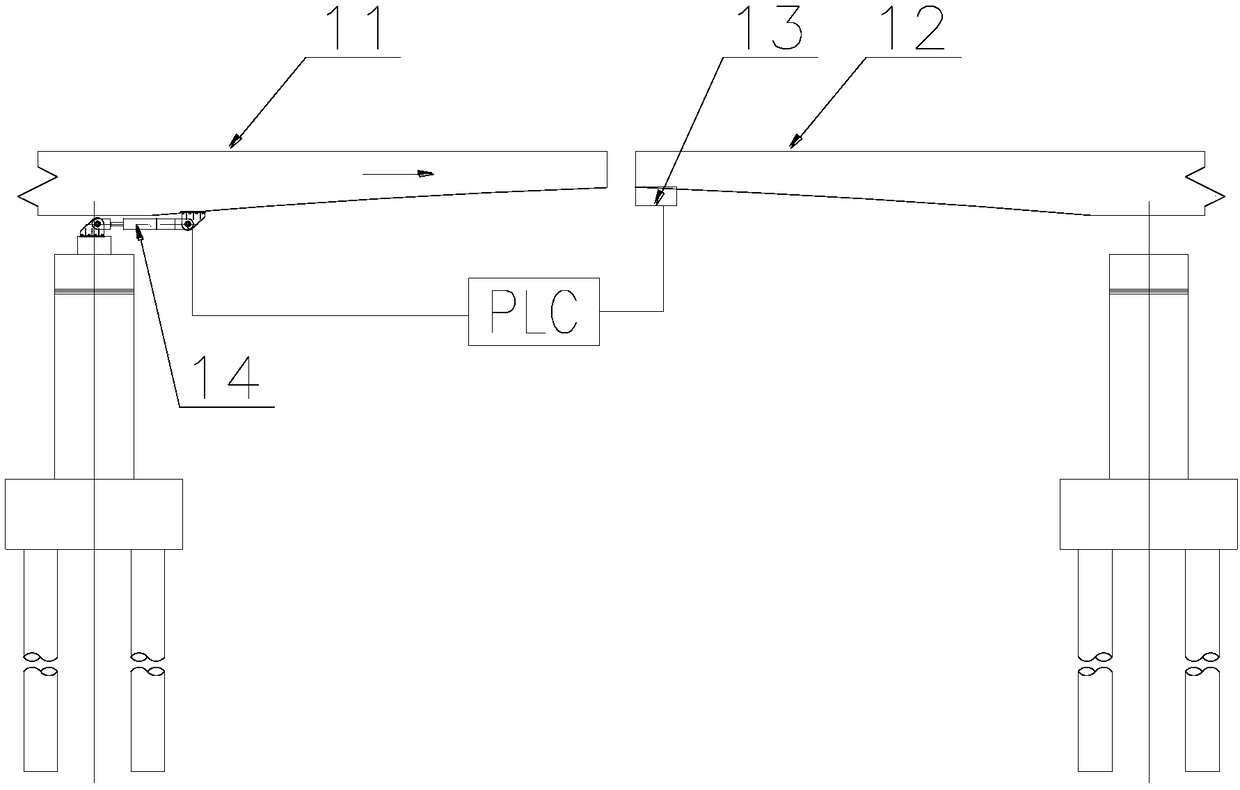

[0023] Such as figure 1 As shown, the hydraulic servo system for accurate closing of bridges provided by the present invention includes a segmental beam 11 equipped with a pushing device between the pier and the opposite beam 12 to be closed, and is characterized in that it also includes a PLC control unit. The beam 12 is provided with a sensor 13 for sensing the distance from the segmental beam 11 .

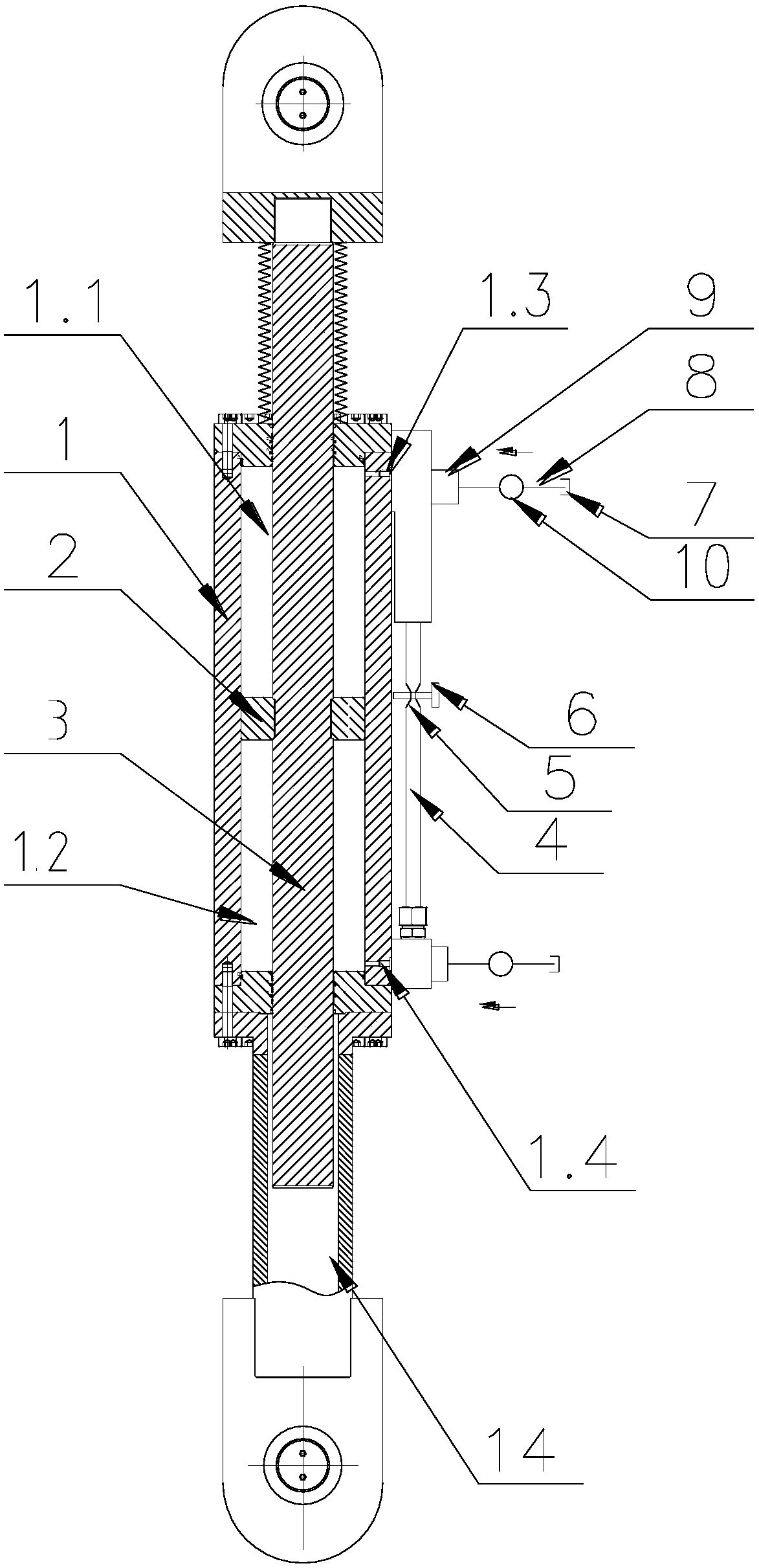

[0024] Such as figure 2 As shown, the pushing device is a viscous damper 14 with a jacking function. The viscous damper 14 includes a cylinder 1, a piston 2, and a piston rod 3. The piston 2 divides the cylinder 1 into a first damping chamber 1.1 And the second damping chamber 1.2, the first damping chamber 1.1 and the second damping chamber 1.2 are filled with damping medium, the first damping chamber 1.1 and the second damping cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com