Electrode slice slitting device

A technology of electrode sheet and cutter, applied in shearing device, cutter for shearing machine, maintenance and safety accessories, etc., can solve the problems of more oil dripping, insufficient dripping, affecting the quality of finished products, etc. Good performance, reduced burr, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

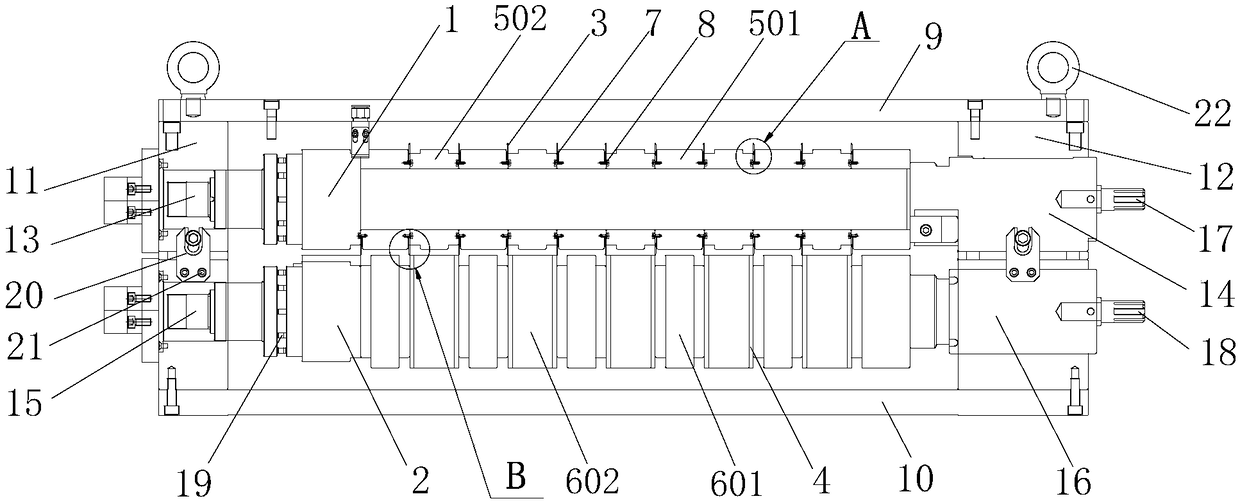

[0073] Such as Figure 1-4 As shown, this embodiment provides an electrode sheet slitting device, which includes a frame, a first slitting mechanism, a second slitting mechanism, a connecting mechanism, and an oiling mechanism;

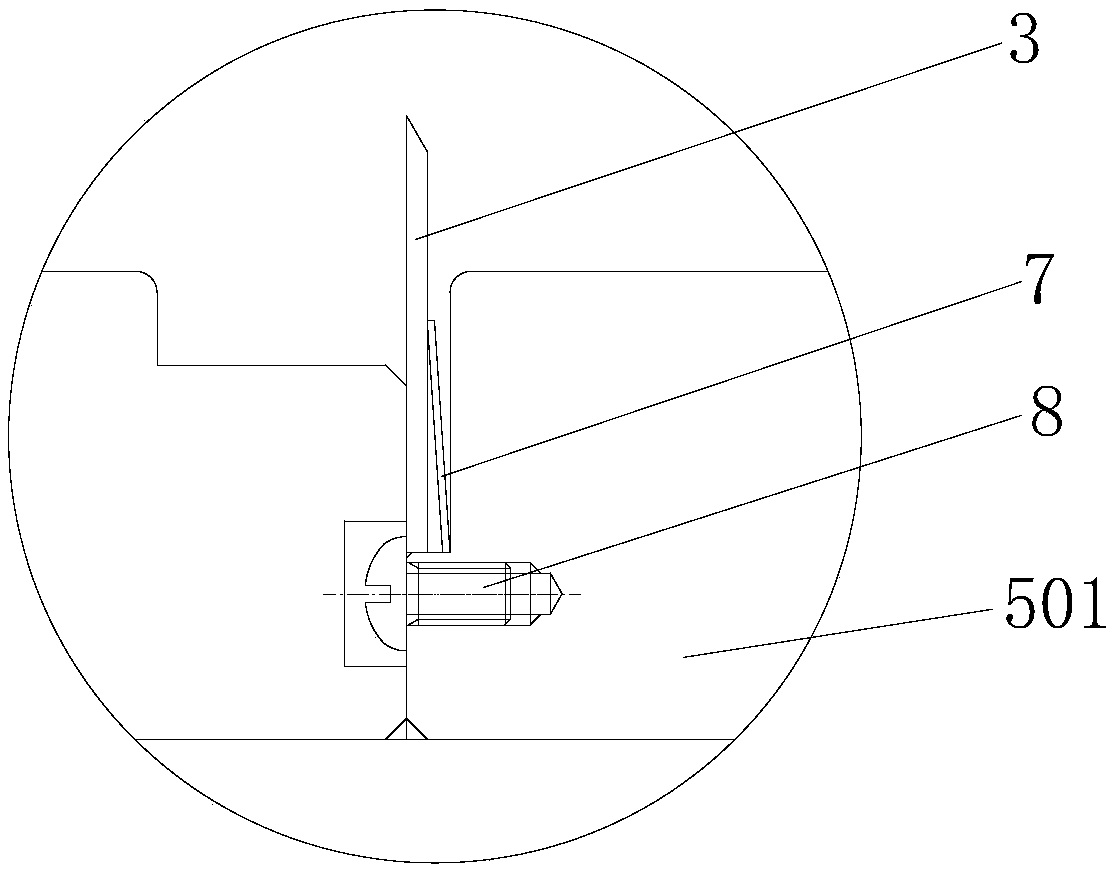

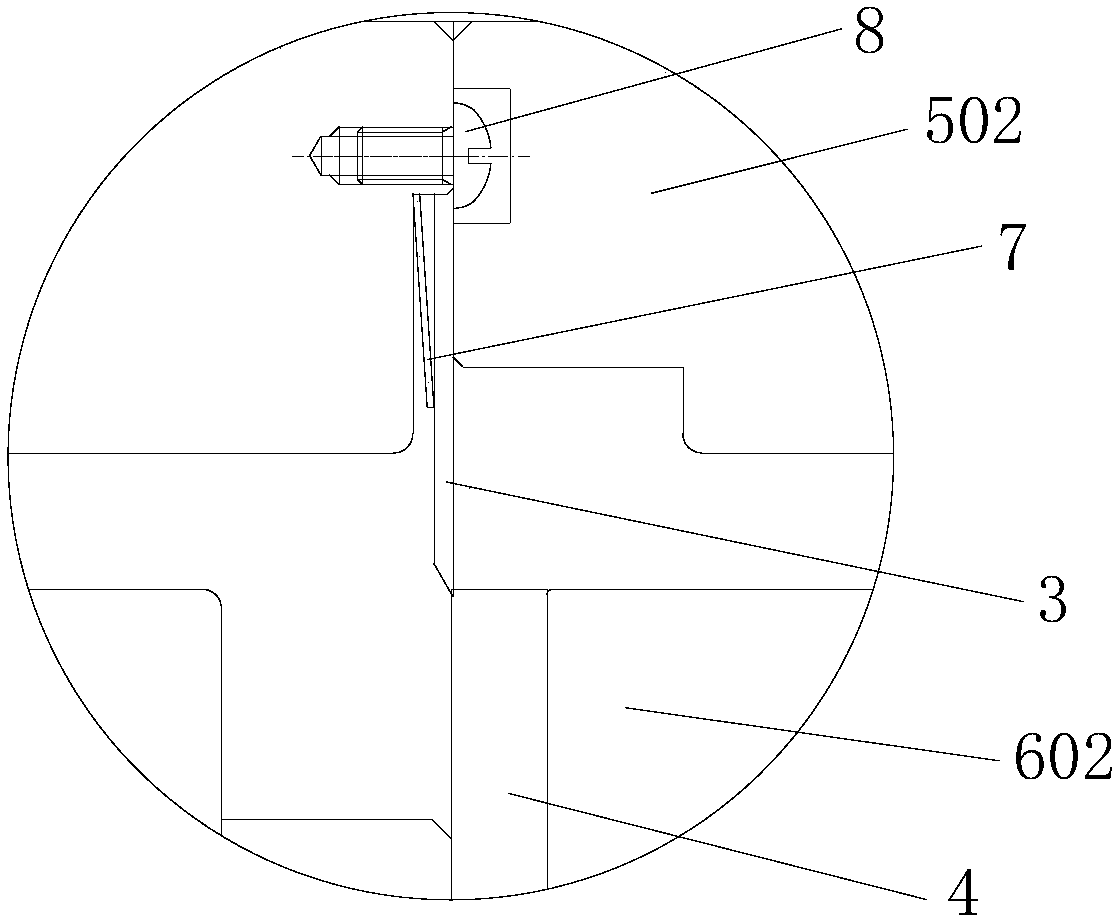

[0074] The first slitting mechanism includes a first knife rest 1, a plurality of first cutting knives 3 and a plurality of first clamping sleeves 5, and the plurality of first cutting knives 3 are arranged on the first knife rest 1 at intervals , The first ferrule 5 is arranged between every two adjacent first cutters 3;

[0075] The second slitting mechanism includes a second knife holder 2, a plurality of second cutting knives 4 and a plurality of second clamping sleeves 6, and the plurality of second cutting knives 4 are arranged on the second knife holder 2 at intervals , The second ferrule 6 is arranged between every two adjacent second cutters 4;

[0076] The first slitting mechanism and the second slitting mechanism are respectively arranged on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com