High-strength precise container metal seal part assembly die

A metal seal and precision technology, applied in the field of high-strength precision seal combination molds, can solve the problems of poor sealing effect, low product accuracy, poor strength, etc., and achieve the effect of reasonable overall structure, high overall accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

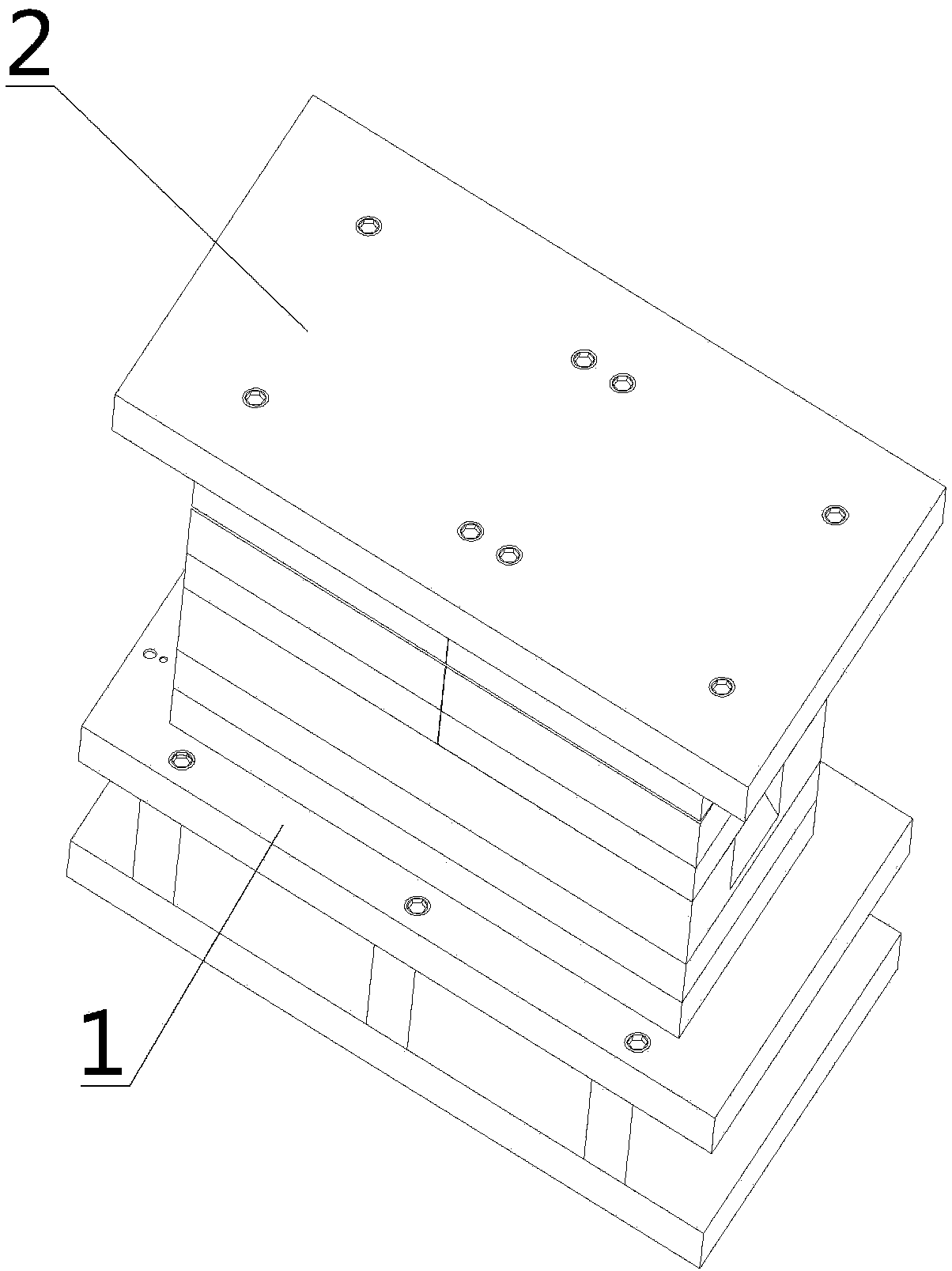

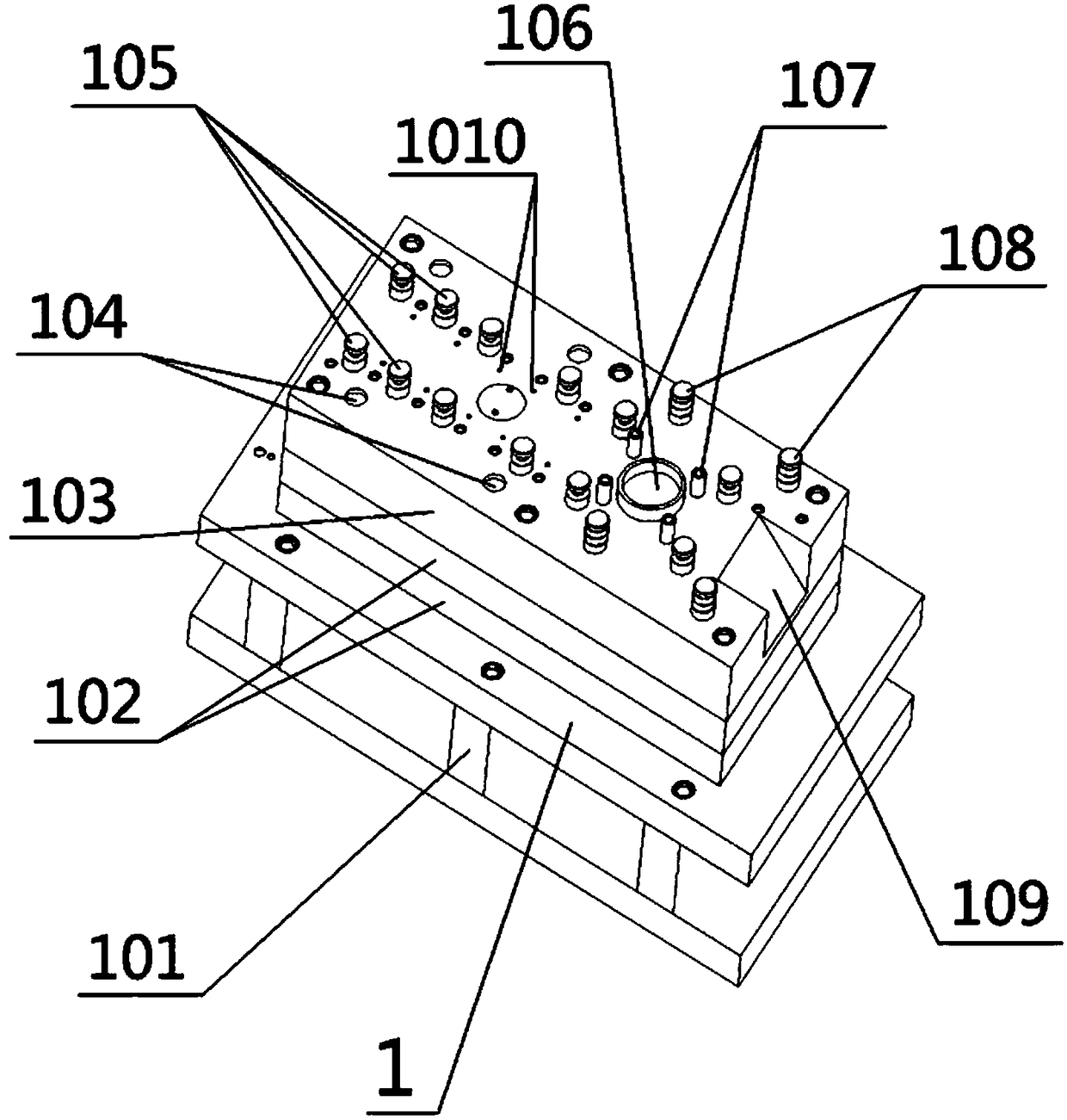

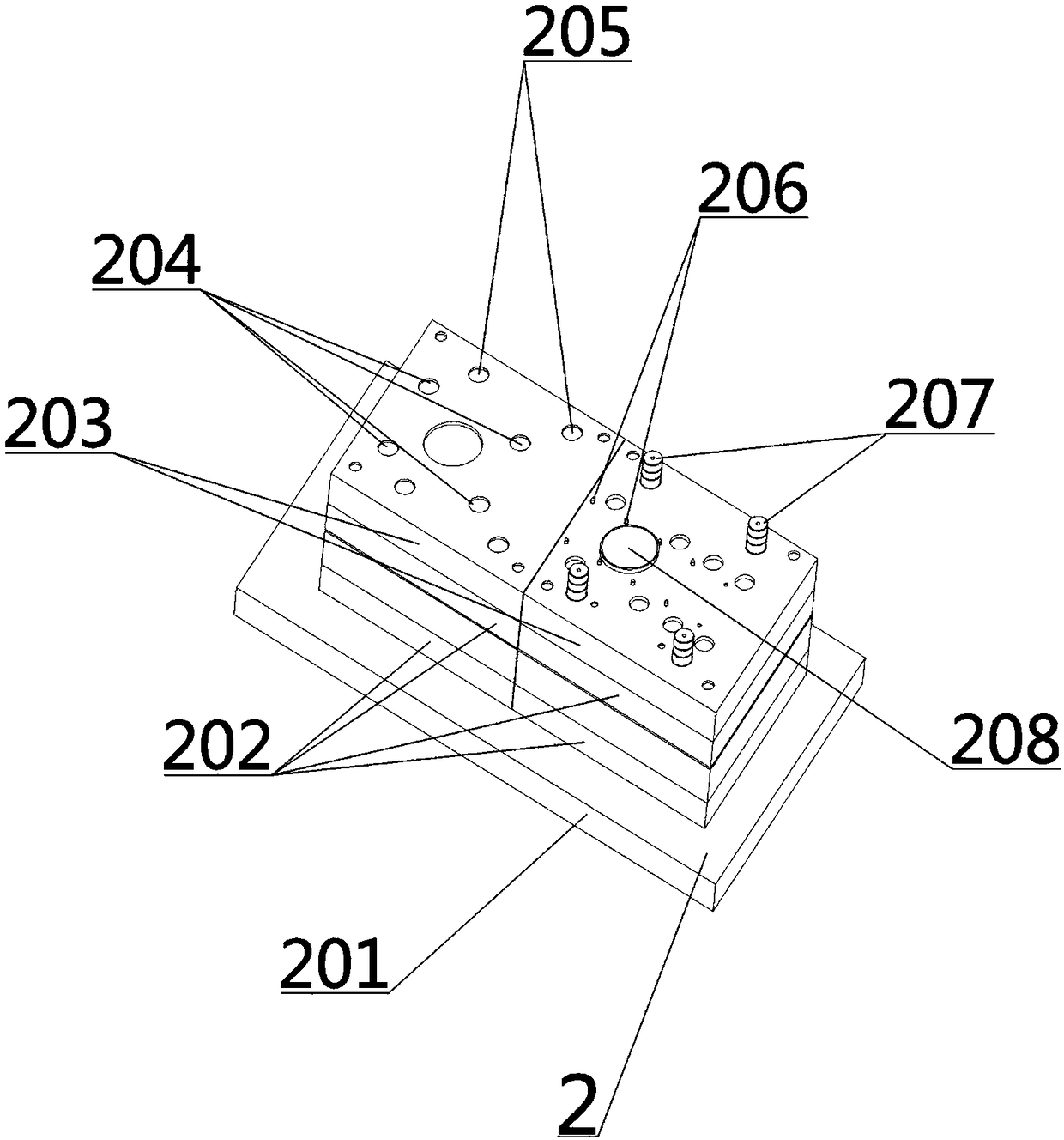

[0011] Referring to the accompanying drawings, a high-strength precision container metal seal mold set is characterized by comprising an upper mold base 2 and a lower mold base 1, and the lower mold base 1 includes a mold base 101, a lower mold plate 103, a lower mold backing plate 102, a lower mold base 1 Die 106, lower die guide post 108, lower die guide hole 104, guide limit post 105, blanking groove 109, positioning pin hole post 107 and pull pin hole 1010, die base 101 is installed on the production equipment, and lower die pad There are two plates 102. After the lower mold backing plate 102 is connected with the lower formwork 103, it is integrally installed and fixed above the formwork 101. There is a blanking groove 109 with a slope in the middle of one end of the lower formwork 103. The lower mold 106 is fixed on the lower formwork 103. There is a groove in the middle of the mold 106, the lower mold guide post 108 is installed on the lower template 103, the lower mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com