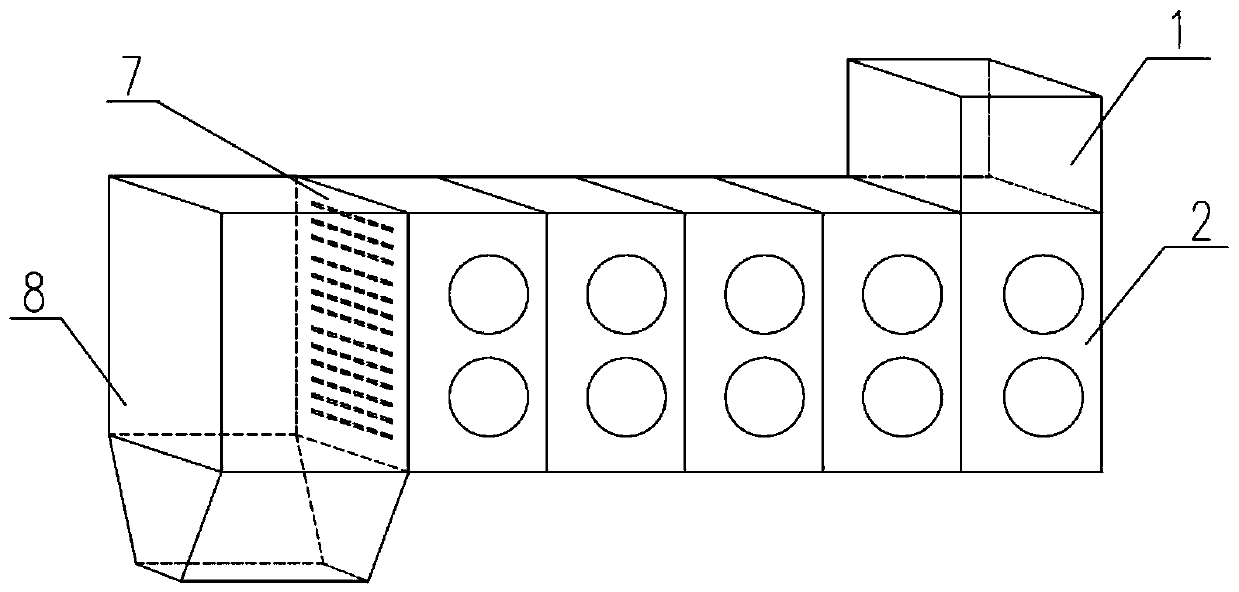

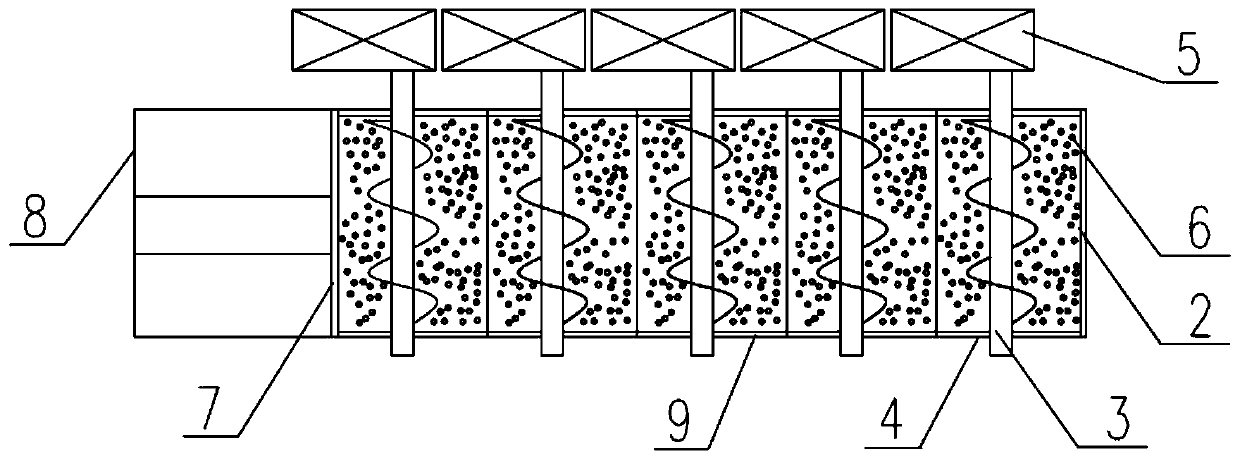

A particle shaping method and particle shaping machine for cement particles

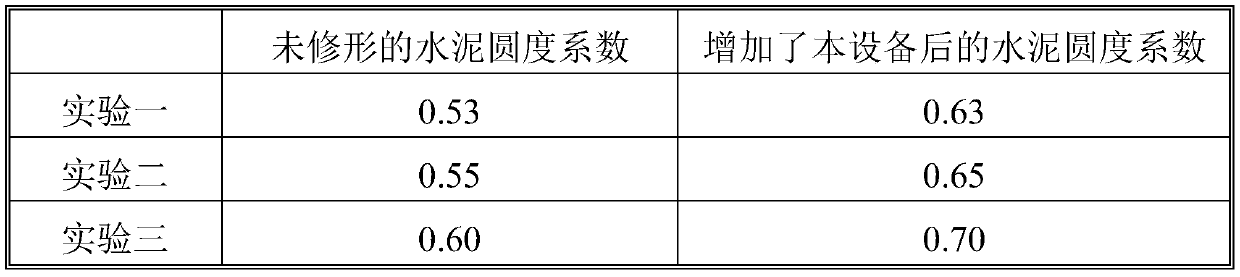

A shaping machine and particle technology, applied in grain processing and other directions, can solve problems such as affecting the normal use of cement, shortening setting time, and large water demand for final grinding cement, and achieve the effect of improving the performance of roller press final grinding cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] First of all, it should be noted that the specific structure, characteristics and advantages of the particle shaping method for cement particles and the particle shaping machine of the present invention will be specifically described below by way of example, but all descriptions are only for illustration , and should not be construed as forming any limitation on the present invention. In addition, any single technical feature described or implied in each embodiment mentioned herein, or any single technical feature shown or implied in each drawing, can still be described in these technical features (or their equivalents) ) to continue any combination or deletion, so as to obtain more other embodiments of the present invention that may not be directly mentioned herein. In addition, for the sake of simplifying the drawings, the same or similar technical features may only be marked in one place in the same drawing.

[0026] It will be understood that when a component is re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com