Method for 1T-phase molybdenum disulfide/graphene nano composite material by hydrothermal process

A technology of nanocomposite materials and molybdenum disulfide, applied in chemical/physical processes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as complex operations, harsh reaction conditions, and low yields, and achieve operational progress The effect of simplicity and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

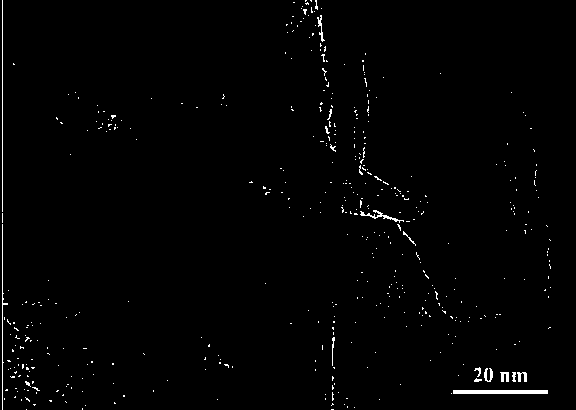

Image

Examples

Embodiment 1

[0021] Take 10 mg of graphene oxide and put it into 10 ml of water for 30 min to form a homogeneous solution, add 20 mg of ammonium molybdate, 40 mg of thiourea and 100 mg of citric acid into the above solution and stir until dissolved, then transfer the solution to the reaction kettle, put into the oven and heated to 200 o C was reacted for 24 h; after the reaction was completed, it was cooled to room temperature, the product was washed with water and ethanol, centrifuged, 60 o C dried to obtain 1T phase molybdenum disulfide / graphene nanocomposites.

Embodiment 2

[0023] Take 5 mg of graphene oxide and put it into 20 ml of water for 60 min to form a homogeneous solution, add 15 mg of molybdenum trioxide, 45 mg of thiourea and 100 mg of urea into the above solution and stir until dissolved, transfer the solution to the reaction kettle, put Oven heated to 240 o C was reacted for 12 h; after the reaction was completed, it was cooled to room temperature, the product was washed with water and ethanol, and centrifuged at 80 o C dried to obtain 1T phase molybdenum disulfide / graphene nanocomposites.

Embodiment 3

[0025] Put 20 mg of graphene oxide into 50 ml of water and ultrasonicate for 120 min to form a homogeneous solution, add 25 mg of sodium molybdate, 45 mg of thioacetamide and 120 mg of oxalic acid into the above solution and stir until dissolved, transfer the solution to the reaction kettle, Put in the oven and heat to 180 o C was reacted for 24 h; after the reaction was completed, it was cooled to room temperature, the product was washed with water and ethanol, centrifuged, 70 o C dried to obtain 1T phase molybdenum disulfide / graphene nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com