Fuel supply system and method for shock tunnel scramjet engine air intake test

A fuel supply system, shock tunnel technology, applied in gas turbine engine testing, jet engine testing, aerodynamic testing, etc., can solve problems such as weakness, achieve stable fuel injection pressure, ensure safety, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

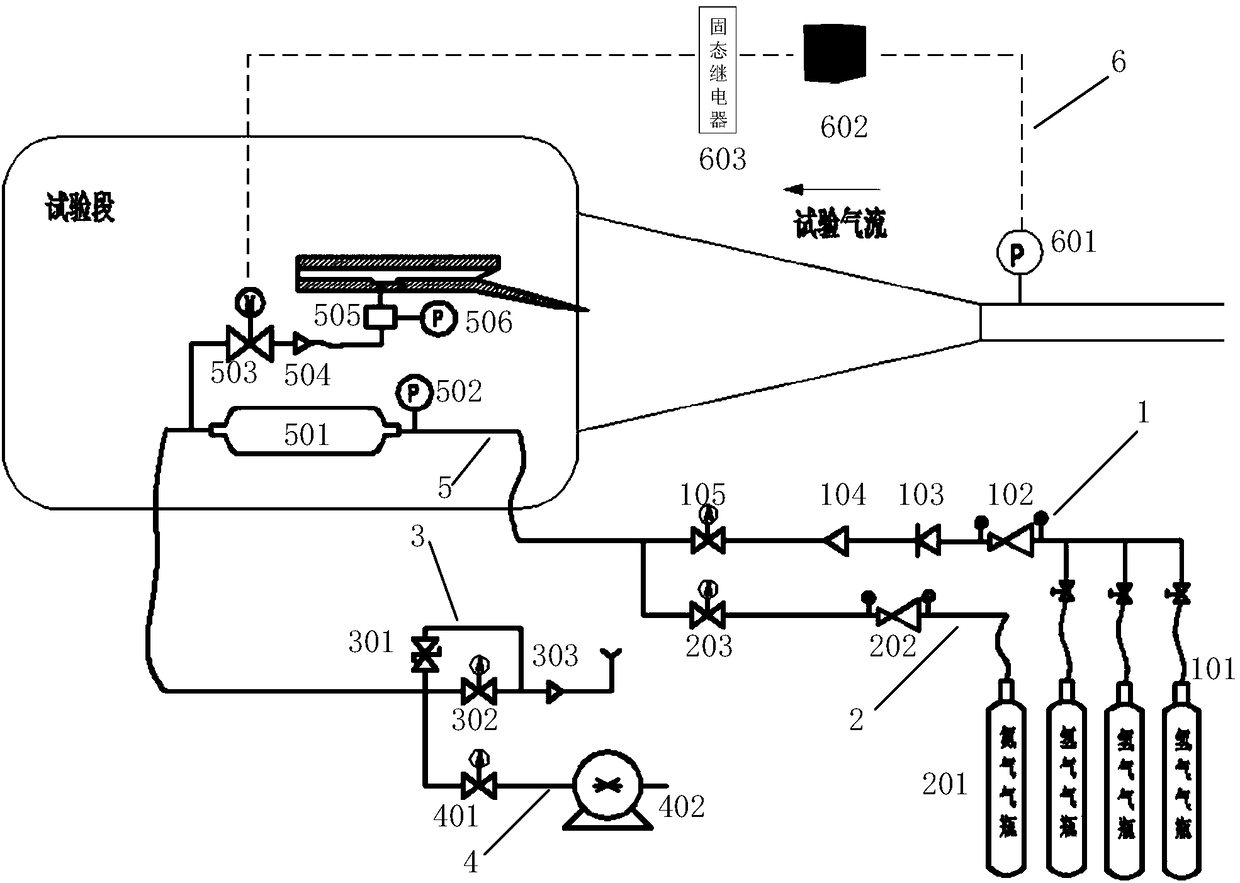

[0033] A fuel supply system for a shock tunnel super-combustion engine inlet test, the system includes a hydrogen filling branch 1, a nitrogen replacement branch 2, an emptying branch 3, a vacuuming branch 4, a fuel injection branch Flow branch 5 and fuel injection flow control part 6;

[0034] The hydrogen filling branch 1 includes a hydrogen gas source 101, a hydrogen pressure reducing valve 102, a one-way valve 103, a hydrogen tempering device 104, a hydrogen branch valve 105 and pipelines;

[0035] The nitrogen replacement branch 2 includes a nitrogen gas source 201, a nitrogen branch pneumatic valve 202, a nitrogen branch valve 203 and pipelines;

[0036] The evacuation branch 3 includes a hydrogen safety valve 301, an evacuation valve 302, a hydrogen temperer 303 and pipelines;

[0037] The vacuum branch 4 includes a vacuum branch valve 401, a vacuum pump 402 and pipelines;

[0038]The fuel injection branch 5 includes a buffer tank 501, a buffer tank pressure sensor 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com