Printing device capable of achieving quick drying conveniently based on environment-friendly printing technology

A process technology and fast drying technology, applied in printing devices, printing and other directions, can solve the problems of drying and pressing of paper that affect diversity, paper wrinkle, and cannot be printed, so as to avoid paper wrinkle and facilitate extrusion. Paper, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

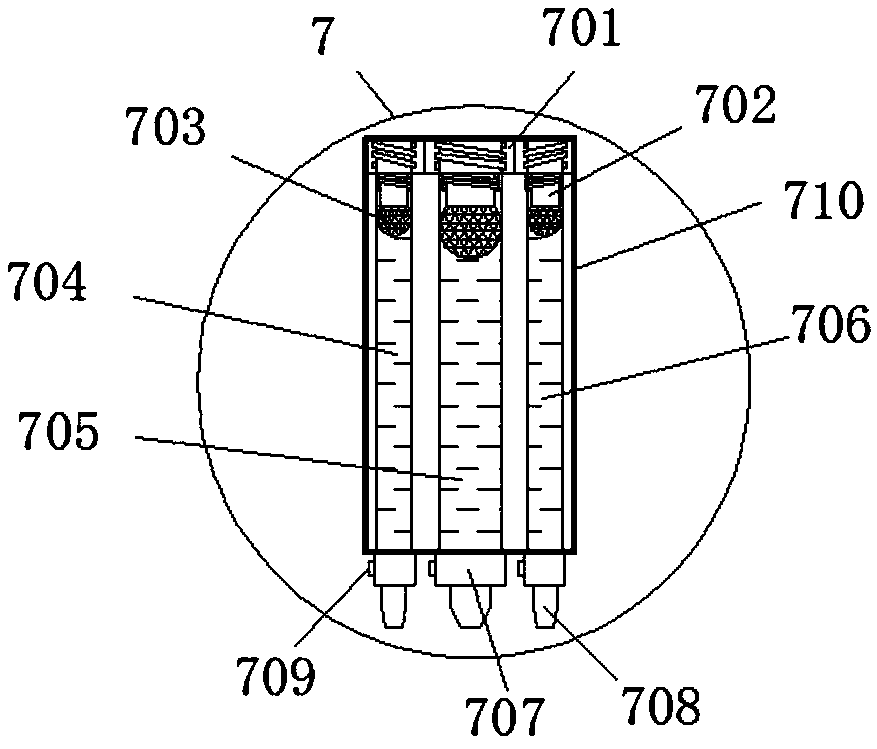

[0030] Example 1, such as image 3The middle inkjet device 7 comprises a first set of buttons 701, a second set of buttons 702, a paint bag 703, a basket ink barrel 704, a black ink barrel 705, a red ink barrel 706, a connection barrel 707, an inkjet nozzle 708, a water pipe head 709 and Fixed box 7010, the middle side of fixed box 7010 is provided with basket ink bucket 704, black ink bucket 705 and red ink bucket 706 successively from left to right, the upper side of fixed box 7010 is provided with first set of buckles 701, the first set of buckles The lower end of 701 is fixed with a second set of buckles 702, the lower end of the second set of buckles 702 is connected with a paint bag 703, the lower end of the fixed box 7010 is provided with a connecting barrel 707, and the lower end of the connecting barrel 707 is provided with an inkjet nozzle 708, and the connecting barrel 707 The outer surface of the outer surface is connected with a water pipe head 709, which is conve...

Embodiment 2

[0031] Example 2, such as Figure 5 The middle air vent 13 includes an air hole 1301, a dustproof plate 1302 and a channel 1303. The inner side of the air hole 1301 is provided with a channel 1303, and the left and right sides of the channel 1303 are provided with a dustproof plate 1302. The shape of the dustproof plate 1302 is an arc structure. , the longitudinal section shape of the vent 13 is a right-angled trapezoidal structure, and the inner side of the vent 13 is equidistantly distributed with 3 fans 14, and the central axes of the 3 fans 14 are all arranged parallel to the waistline of the vent 13, so as to be convenient to the bottom of the vent 13. The arrangement shape of the heating wire 15 on the side fits well, and it is also convenient to reduce the dust from entering the inside of the device from the vent 13, which will affect the quality of printing.

Embodiment 3

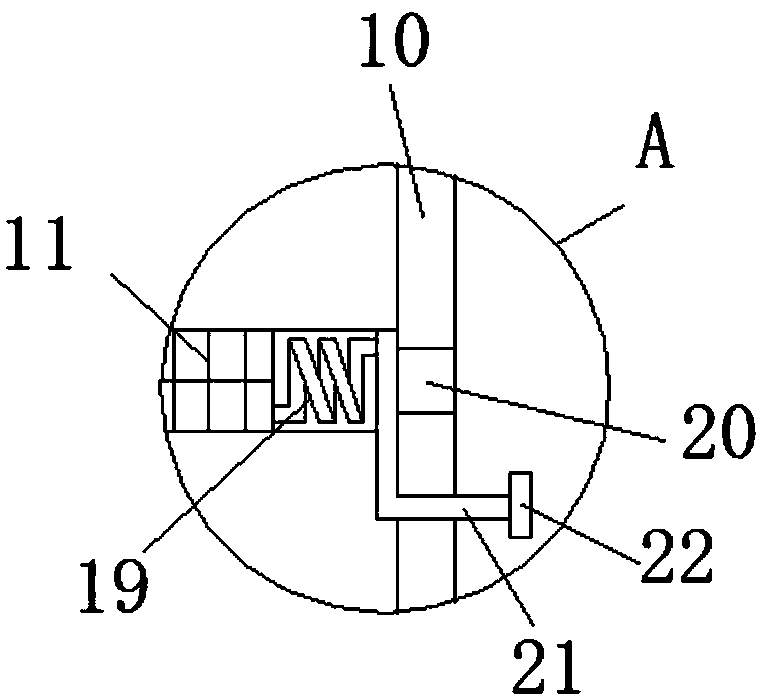

[0032] Example 3, such as figure 2 The middle pull rod 21 forms a telescopic structure through the spring 19 and the filter screen 11, and the shape of the pull rod 21 is an "L" shape, which is convenient for adjusting the position of the pull rod 21, and is convenient for the pull rod 21 to squeeze the spring 19 to realize the filter screen 11 from the ink tank 10. It can be disassembled for easy use.

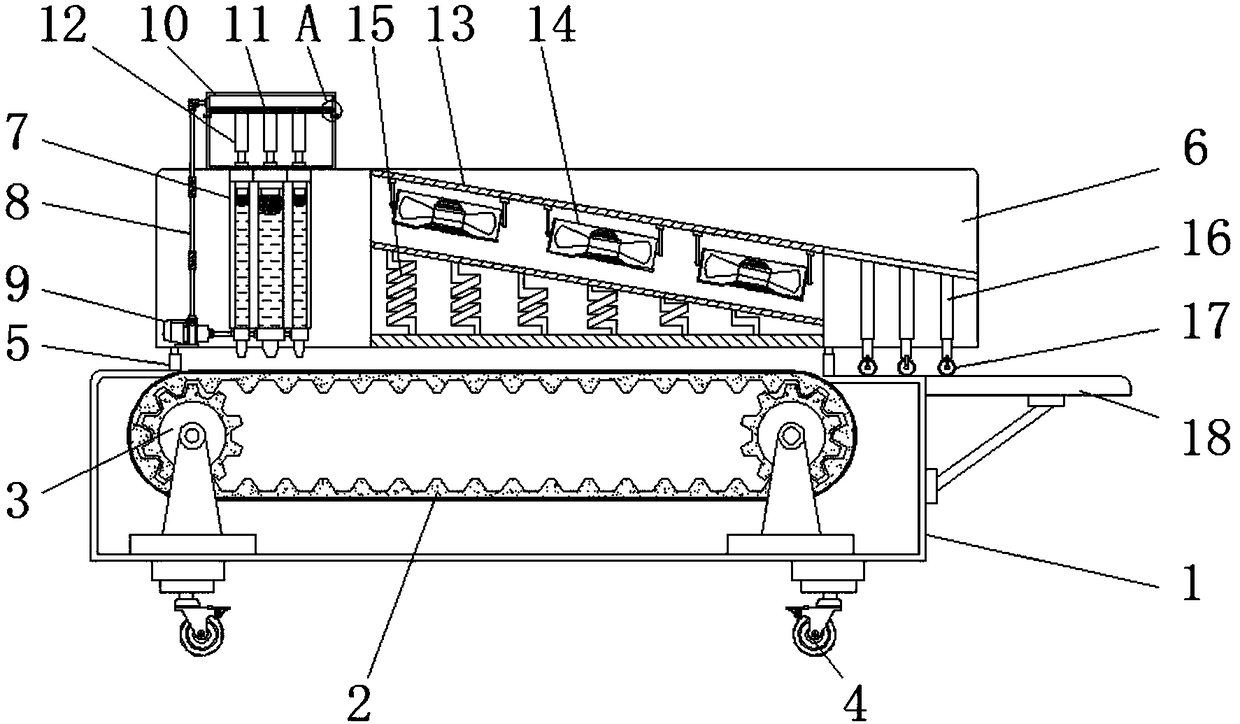

[0033] Working principle: When using the printing device based on the green and environmental protection printing technology that is convenient for rapid drying, first turn on the switch of the motor, and the motor drives the gear 3 to rotate when the motor is working, and the gear 3 drives the conveyor belt 2 to rotate, so as to facilitate the transmission of paper, according to Need to print the color of font, adjust the opening of basket ink barrel 704, black ink barrel 705 and red ink barrel 706 in the inkjet device 7, eject the required color from the inkjet nozzle 708, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com