Humidity control method for dehumidifying and anti-seepage device

A technology of humidity control and humidity, which is applied in the field of building moisture-proof and dehumidification, can solve the problems of low control accuracy and insufficient control flexibility, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

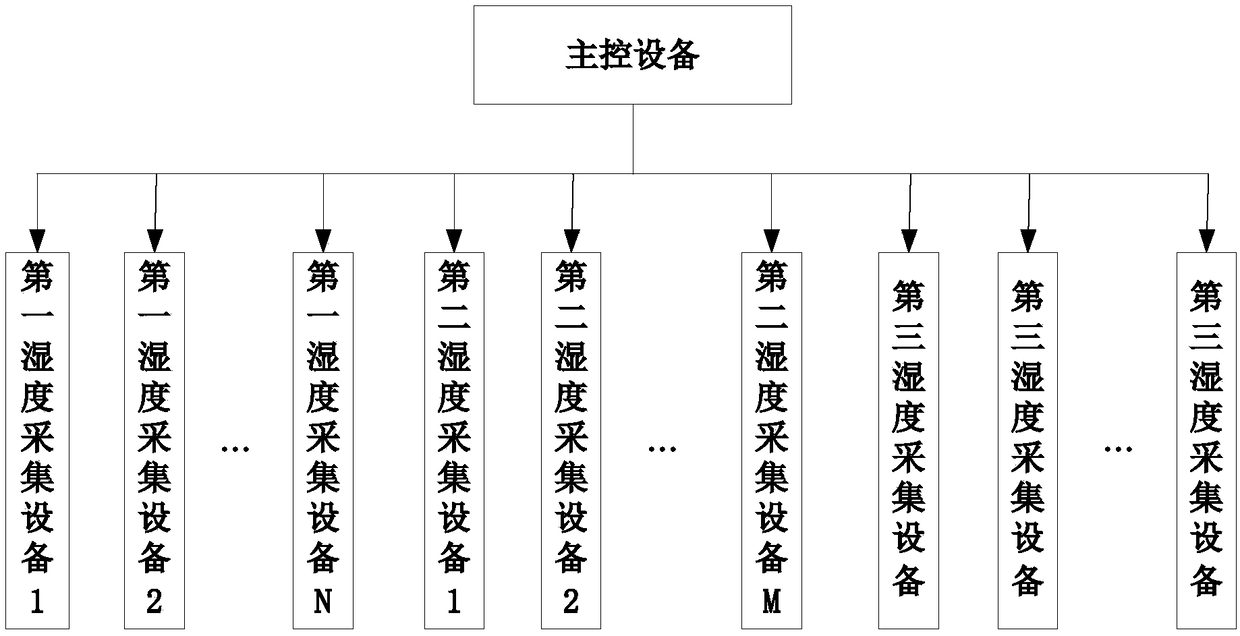

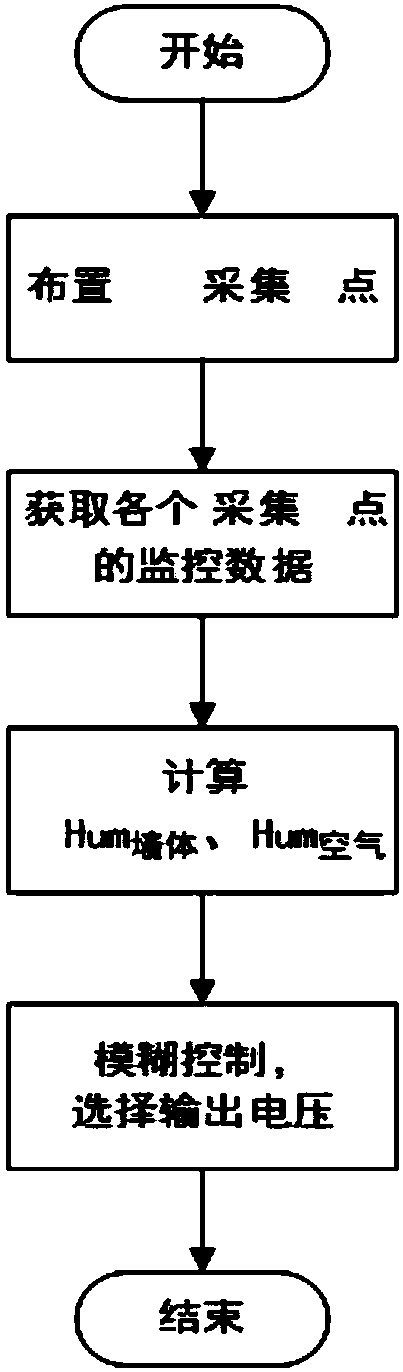

[0094] like figure 1 As shown, the dehumidification and anti-seepage device includes a main control device and a humidity collection device, and the humidity collection device includes a first humidity collection device, a second humidity collection device and a third humidity collection device. The main control device includes a wireless transmitting / receiving module, a micro control unit module, a voltage output module and a GPRS communication module. The humidity collecting device includes a wireless transmitting / receiving module, a micro control unit module and a sensor. The wireless communication module communicates wirelessly with the main control device; the micro control unit module controls the data collection, data processing and sending of the space to be detected; the sensor collects the data of the space to be detected.

[0095] The output voltage of the main control device in a stable working state is related to the indoor air humidity and the humidity in the wa...

Embodiment 2

[0108] Embodiment 2 is basically the same as Embodiment 1. Also, as a person skilled in the art, the following selections can be made to determine the fixed collection point and the mobile collection point of the wall inner surface of the space to be detected in step (1):

[0109] (a) Divide the inner surface of each wall in the space to be tested into D grids, and initially measure the humidity of each grid, where D≥1; D is a natural number;

[0110] (b) Find out the N grids with the highest humidity ranking among the D grids, set a fixed collection point for each grid in the N grids, and set the first humidity collection at each fixed collection point equipment, said N≤D, said N≥1; N is a natural number;

[0111] (c) Utilize the humidity collected by all the first humidity collection devices on the inner surface of each wall to calculate the average humidity of the inner surface of each wall;

[0112] (d) compare the average humidity on the inner surface of each wall, the t...

Embodiment 3

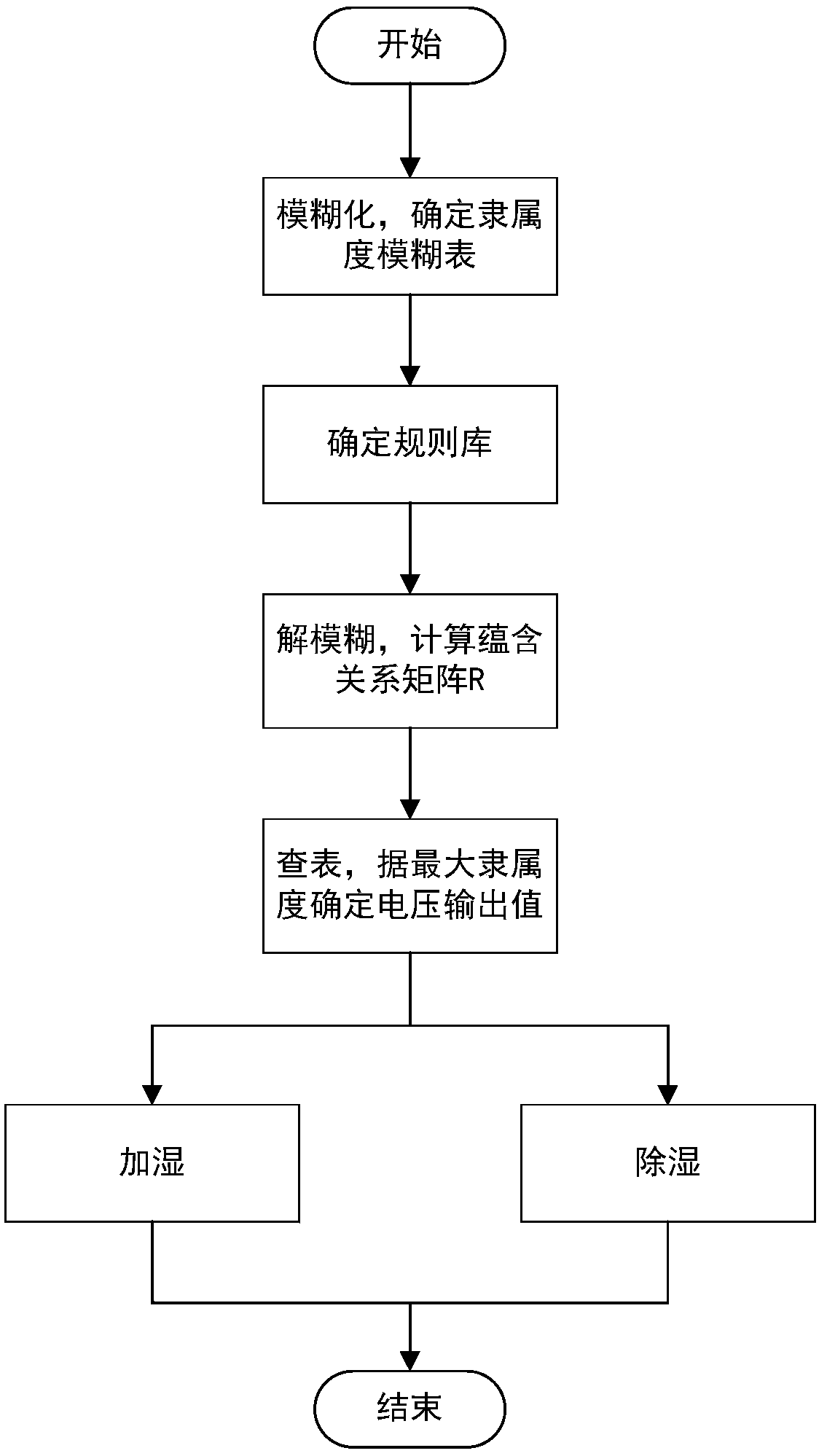

[0124] Embodiment 3 is substantially the same as Embodiment 2, and also in that, as a person skilled in the art, the process of fuzzy control carried out by the fuzzy controller in step (4) is as follows image 3 As shown, as follows:

[0125] (a1) The air comprehensive humidity error δ 空 and wall comprehensive humidity error δ 墙 As the input of the fuzzy controller, the fuzzy control is carried out, and the output of the fuzzy controller is U i , U i The output voltage of the main control equipment in a stable working state;

[0126] (a2) The input quantity δ 空 ,δ 墙 and output U i Carry out the description of fuzzy language separately;

[0127] (a3) Determine fuzzy control rules;

[0128] (a4) Determine the matrix form F of the fuzzy control rules;

[0129] (a5) Carry out fuzzy decision-making to obtain the output voltage U of the main control device under stable working conditions i .

[0130] In this implementation, the comprehensive air humidity error δ 空 and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com