Flow-adjustable centrifugal fuel nozzle of engine

A fuel nozzle and engine technology, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of irreversible debugging process, long debugging cycle, and difficult to adjust the product performance to a high level, so as to save production time and reduce The effect of workload and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

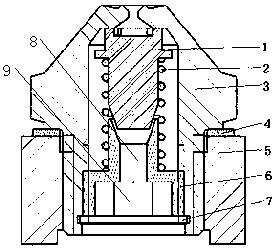

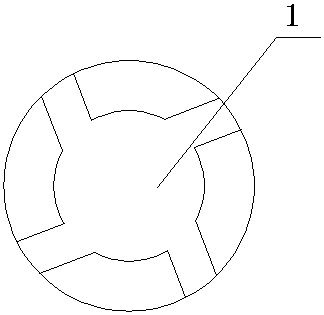

[0015] Such as figure 1 , figure 2 As shown, an engine centrifugal fuel nozzle with adjustable flow rate includes a nozzle housing 5, a swirler 1, a spout 3, and an adjustable screw 6. The nozzle housing 5 is a hollow structure, and the inside of the nozzle housing 5 An internal thread is provided, and an external thread is provided on the lower part of the outer wall of the spout 3, and the external thread of the spout 3 is connected with the internal thread of the nozzle housing 5. The spout 3 is provided with an inner cavity, and the inner cavity is cylindrical, and the inner cavity of the spout 3 The lower part of the adjustable screw 6 is provided with an internal thread, and the outside of the adjustable screw 6 is provided with an external thread, and the external th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com