On-line Measurement Method of Secondary Air of Swirl Burner

A technology of swirl burner and measurement method, which is applied in the direction of combustion method, combustion chamber, and controlled combustion, and can solve the problem of difficulty in measuring the secondary air of swirl burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

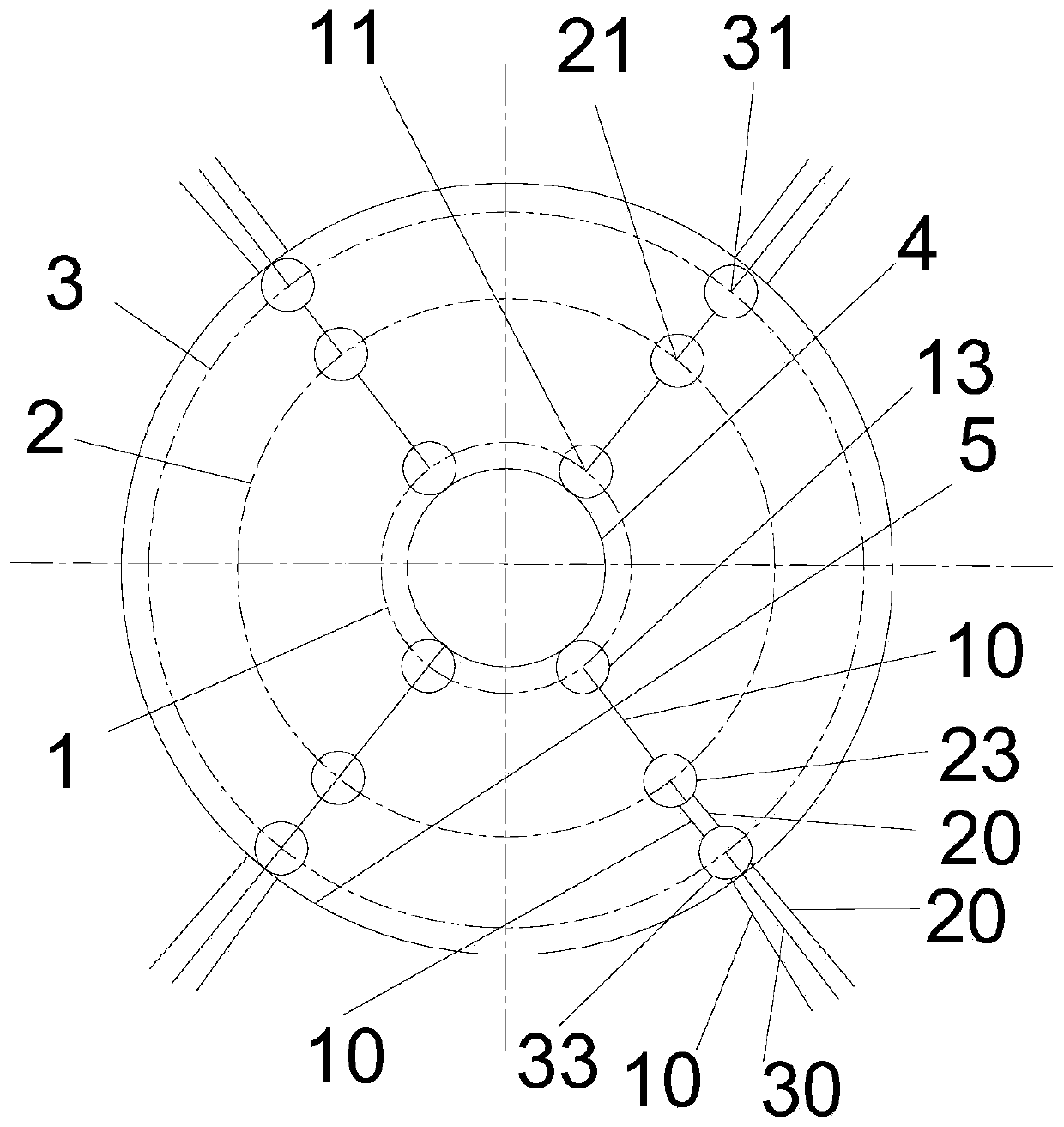

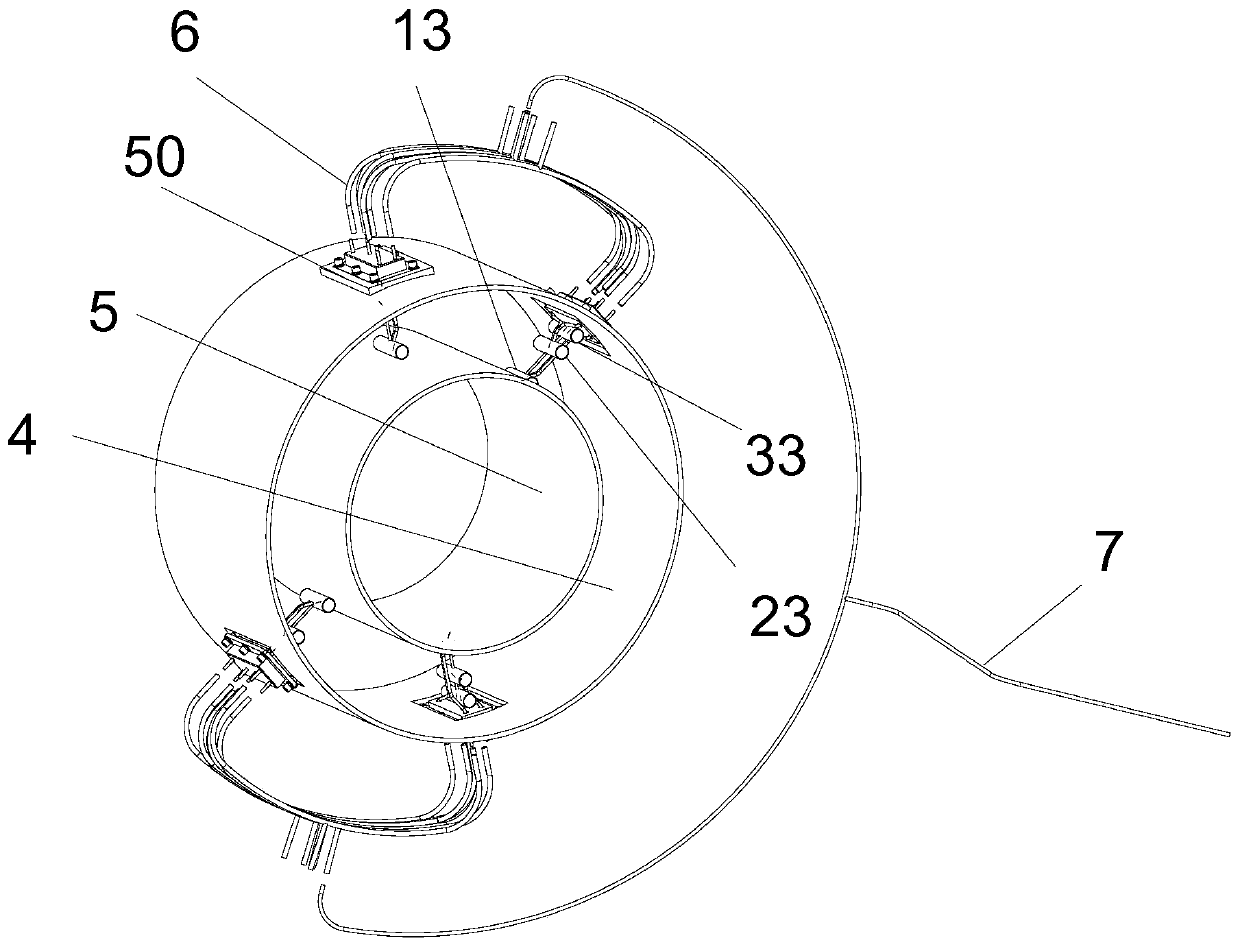

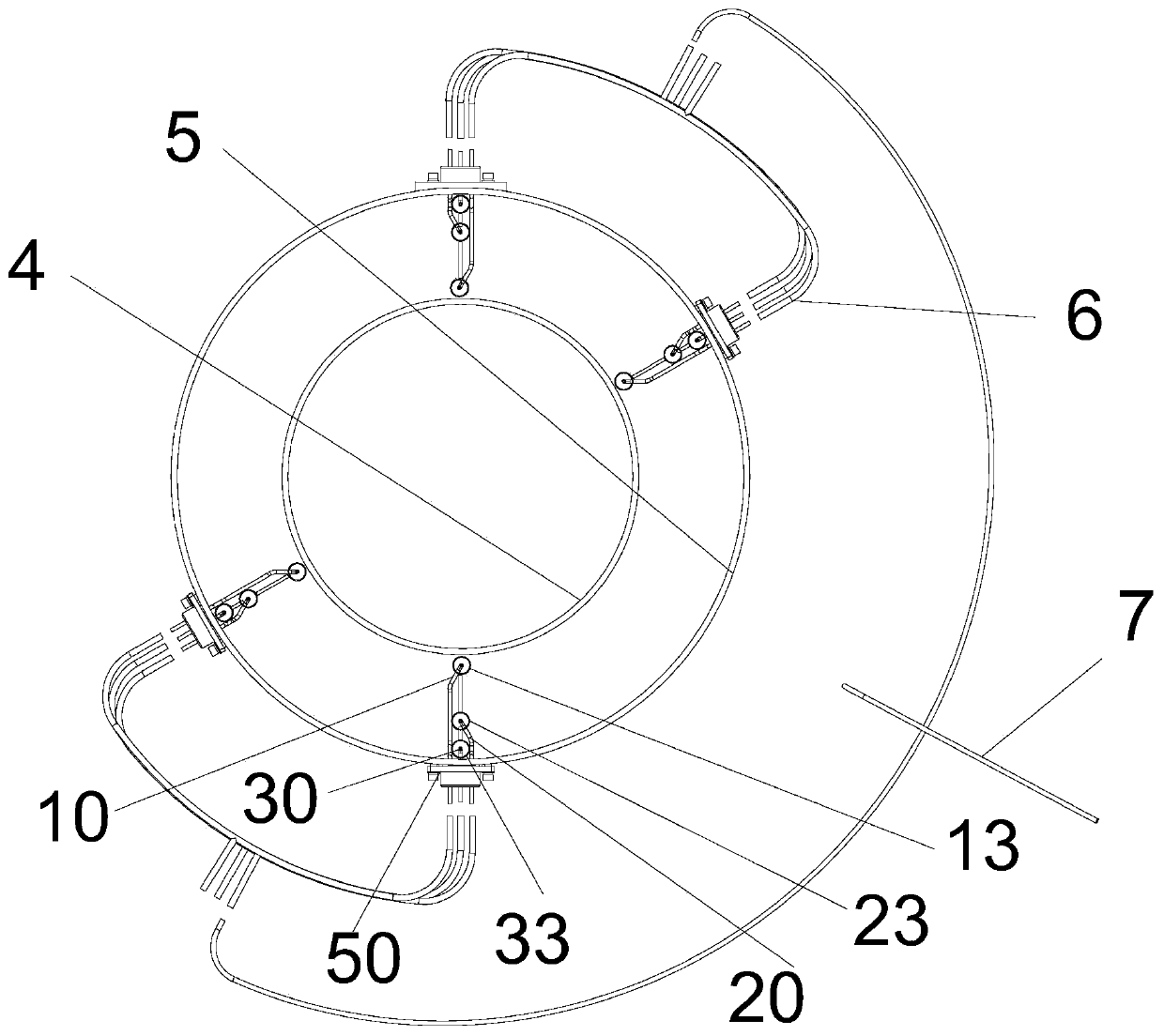

[0083] Such as figure 1 , figure 2 and image 3 As shown, the present invention proposes an online measurement device for secondary air of a swirl burner, which is used to measure the wind speed in the secondary air duct of a swirl burner. The online measurement device for secondary air of a swirl burner includes:

[0084] Three sets of primary measuring elements are radially distributed in three circles of the radial section of the secondary air duct, each set of primary measuring elements includes four primary measuring pieces arranged on the same circumference, each of the primary measuring One piece measures one measuring point, three groups of primary measuring elements contain 12 primary measuring elements in total; each measuring point is provided with one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com