A river floating garbage salvage briquette treatment device

A block treatment and garbage technology, which is applied in the field of river floating garbage salvage and briquetting treatment devices, can solve the problems of limited volume, floating garbage, environmental pollution, etc., and achieve simple and convenient use and operation, obvious working effect, and increase treatment efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

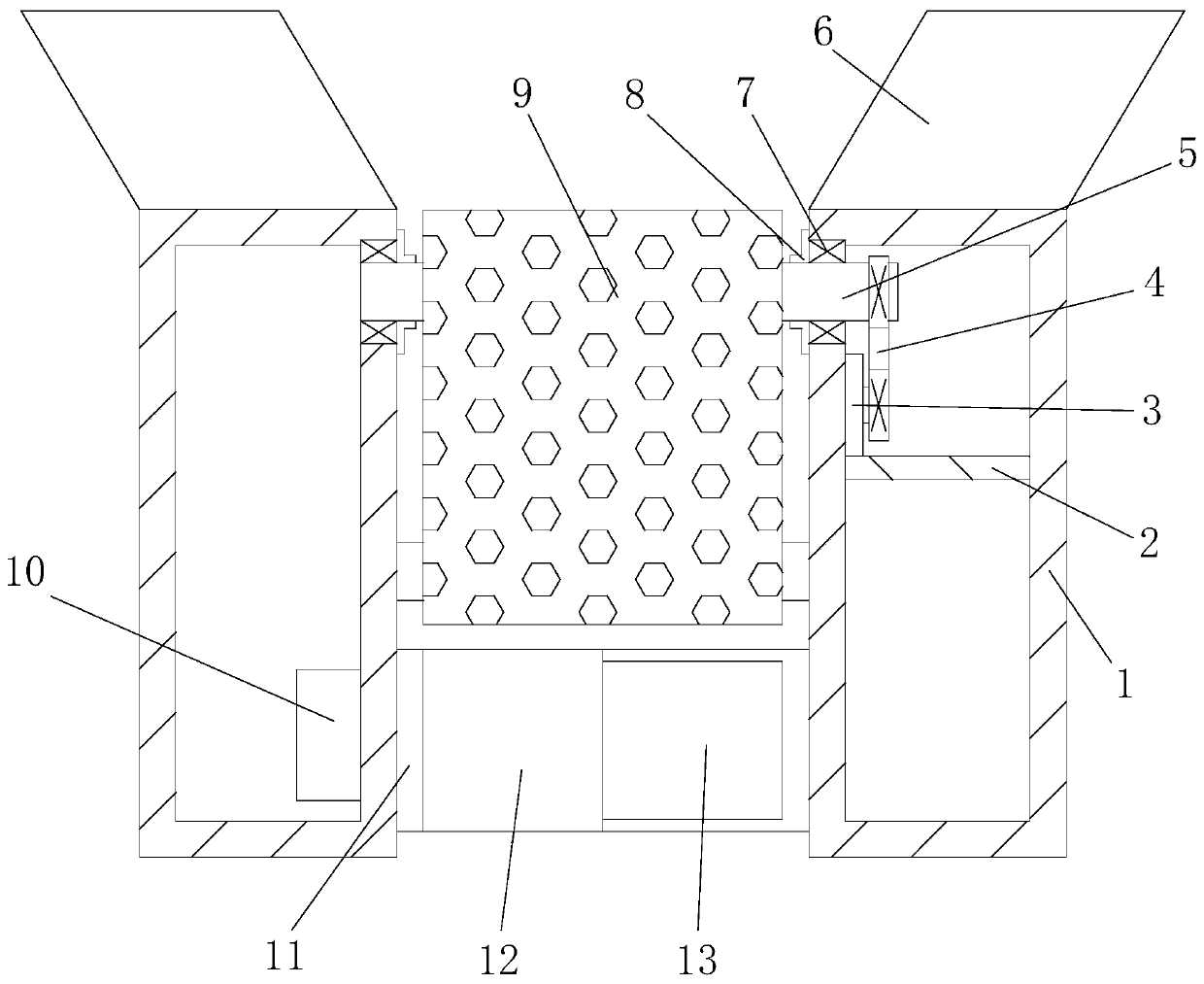

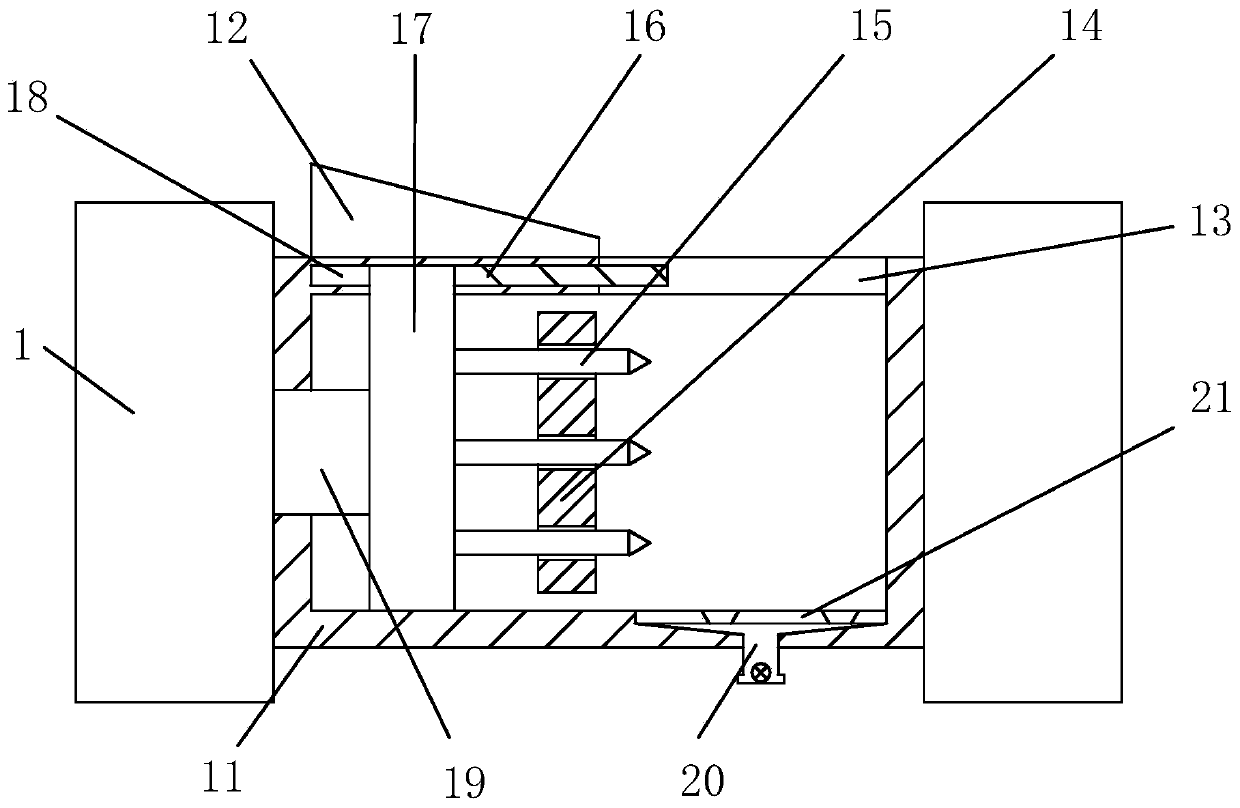

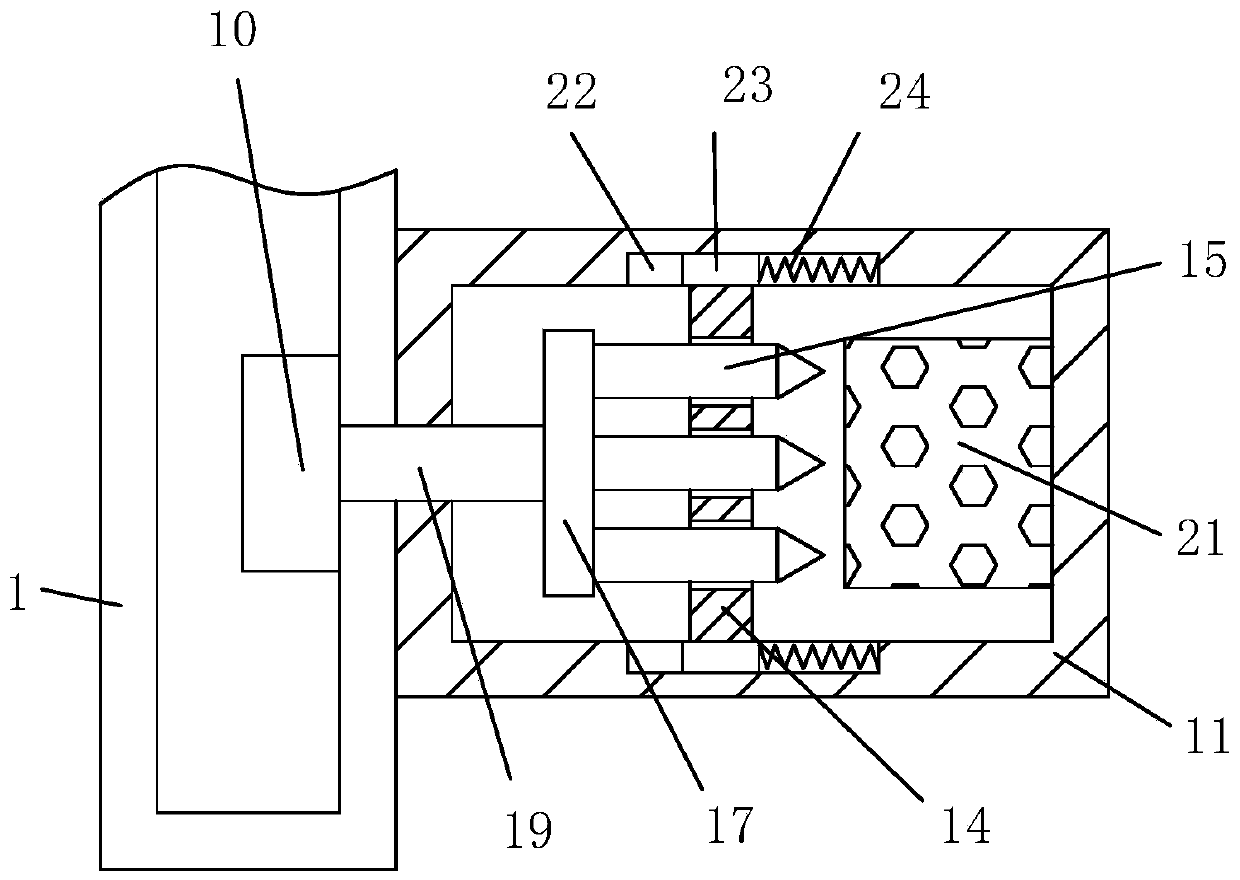

[0021] see Figure 1-4 , a river floating garbage salvage briquette processing device, including a hull 1; the hull 1 is arranged in two left and right arrangements, and its front end is inclined and welded with a deflector 6 to provide installation space for other components on the device; the hull 1 The upper part is provided with a transmission box 2; the transmission box 2 is provided with a transmission motor 3 to protect the transmission parts; the transmission motor 3 is fixed on the wall of the hull 1 by bolts, and a transmission pulley 4 is connected and installed on it for salvage Parts provide power; the transmission pulley 4 is connected upwards on the transmission shaft 5; the transmission shaft 5 is connected horizontally between the hull 1 through the connecting bearing 7, and is arranged behind the deflector 6, and is driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com