Revetment water-stop strip and ecological revetment with same

A technology of water stop strip and limit stop, applied in water conservancy projects, coastline protection, marine engineering and other directions, can solve the problems of difficult construction, high positioning accuracy requirements, easy damage to the pile body, etc., and achieves good effect, convenient construction, Weakening the effect of the crowding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

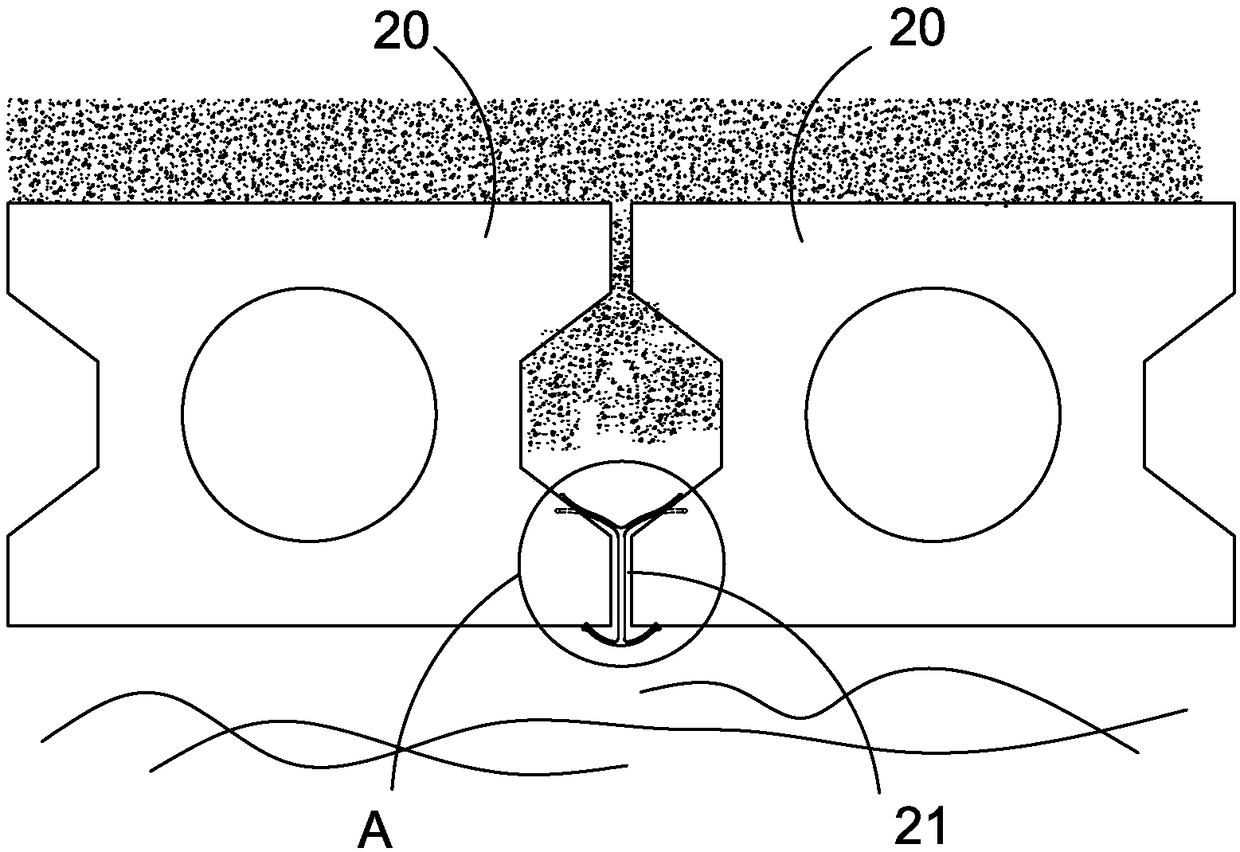

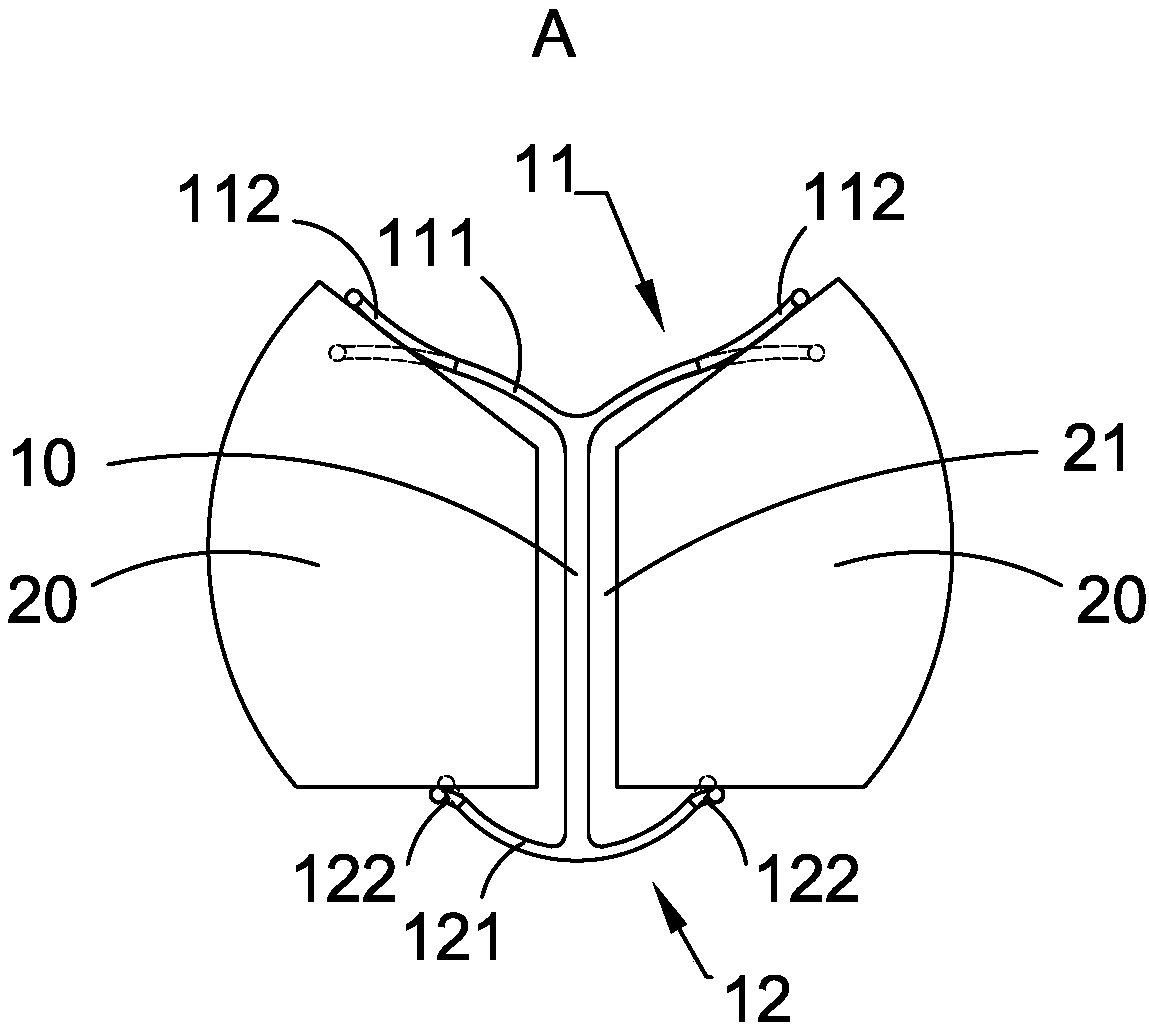

[0031] Embodiment one: as attached figure 1 As shown, a kind of ecological revetment includes a plurality of piles 20 and a plurality of revetment waterstops that are successively sunk in the embankment, and a revetment gap 21 is formed between every two adjacent piles 20, and each revetment waterstop Correspondingly inserted in a corresponding revetment gap 21 . figure 1 The upper side is the side facing the soil, and the lower side is the side facing the water.

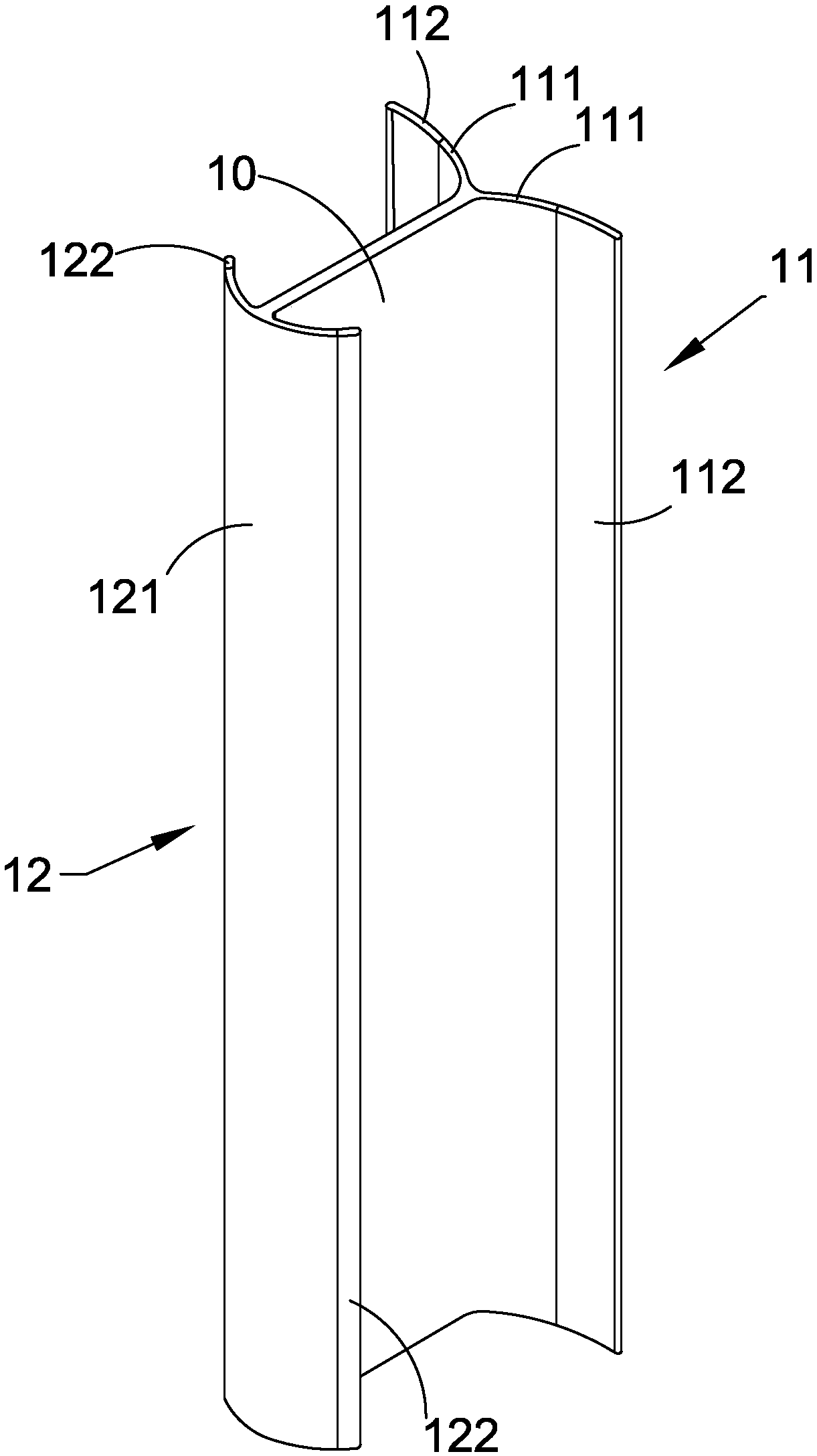

[0032] as attached Figure 1-3 As shown, the revetment waterstop strip includes a slit strip 10 located in the middle for being inserted into the revetment gap 21, a first stopper 11 located at one side of the slit strip 10 to prevent the slit strip 10 from breaking away from the revetment gap 21, and a The opposite side of the seam strip 10 prevents the seam strip 10 from breaking away from the second stopper 12 of the revetment gap 21, as attached figure 1 , 2 As shown, the first limit stop 11 and the second l...

Embodiment 2

[0038] Embodiment two, as attached Figure 4 As shown, the difference between the second embodiment and the first embodiment is that the second stopper 12 of the revetment waterstop strip has no flexible part. The outer surface of the second limit stop main body 121 is an arc-shaped surface, which plays a decorative role. However, in order to play a decorative role, the outer surface of the second limit stop body 121 is not limited to a curved surface, but can also be other, such as a wavy surface.

[0039]The slit strip 10, the first stopper main body 111 and the second stopper main body 121 are made of metal materials, and the first stopper flexible part 112 is wrapped on the slit strip 10 and the first stopper through extrusion processing. Block the main body 111. Arch extrusion processing of metal and plastics also belongs to the prior art process and will not be described in detail.

Embodiment 3

[0040] Embodiment three, as attached Figure 5 As shown, the difference between the third embodiment and the first embodiment is that the second stopper 12 of the revetment water-stop strip has no flexible part. The outer surface of the second limit stop main body 121 is an arc-shaped surface, which plays a decorative role. However, in order to play a decorative role, the outer surface of the second limit stop body 121 is not limited to a curved surface, but can also be other, such as a wavy surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com