Cold and hot loop alternate mold conformal cooling system

A conformal cooling and mold technology, applied in the field of mold conformal cooling system, can solve the problems of loose water distribution, large deformation, and easy cooling, so as to maintain accuracy and stability, reduce residual stress, and control product warpage. the effect of the song

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

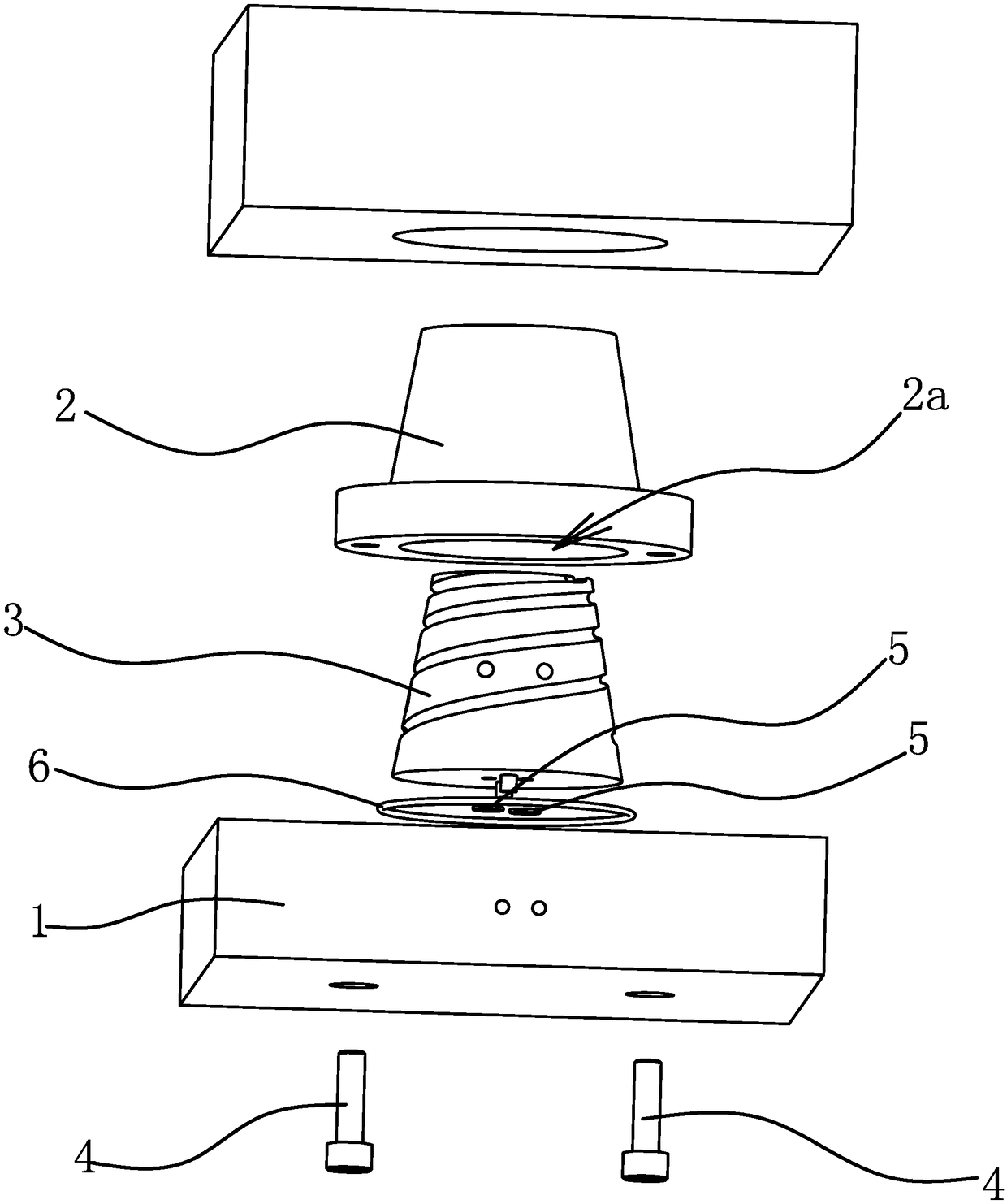

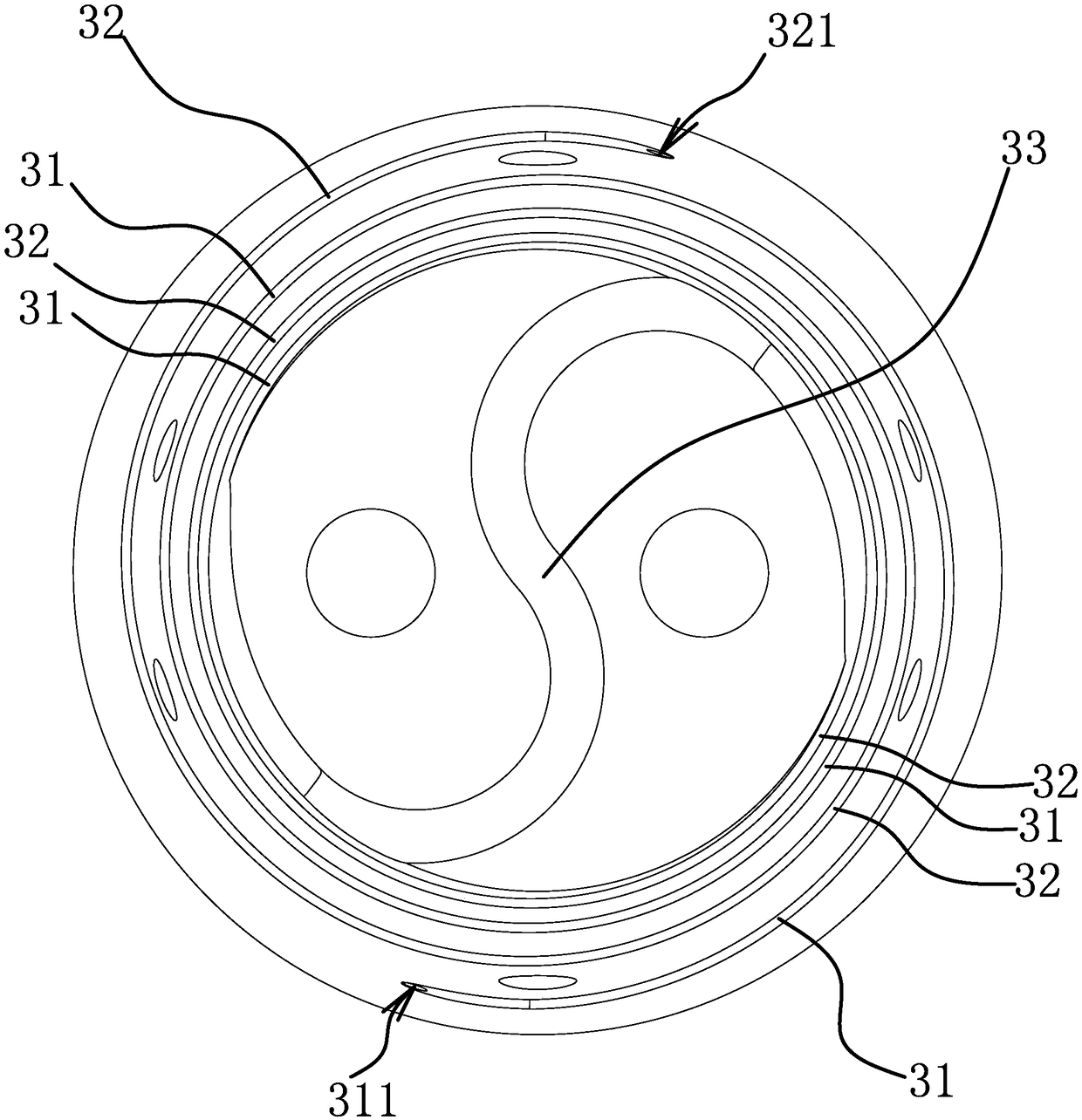

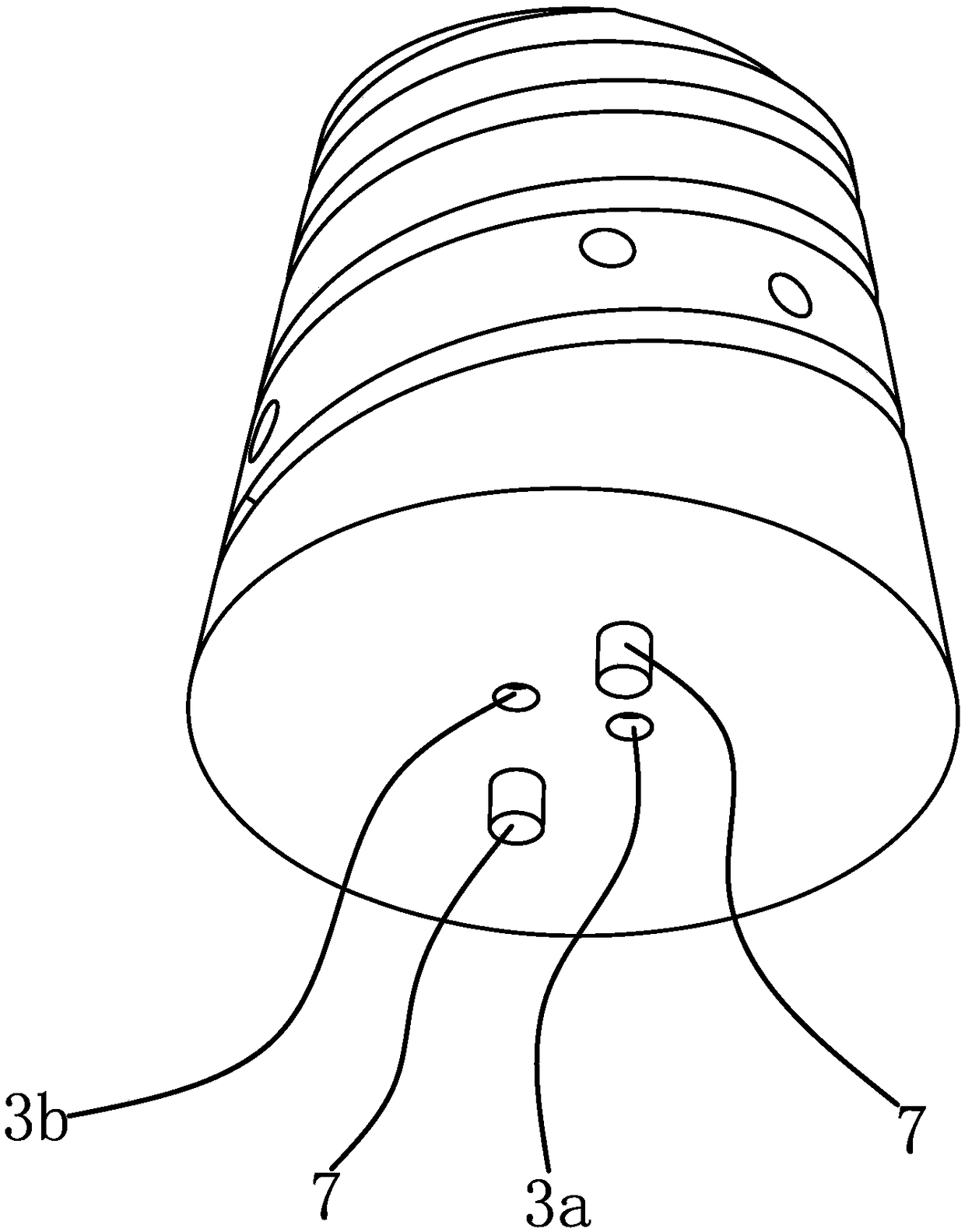

[0027] Specifically, as figure 1 As shown, the mold includes a movable mold 1 and a core 2 fixed on the movable mold 1. The conformal cooling system of the mold with alternating cold and hot circuits includes a cooling cavity 2a in the core 2 and a cooling cavity 2a embedded in the cooling cavity 2a. The inner and frustum-shaped cooling core 3 is a plastic part manufactured by 3D printing technology. Among them, such as figure 2 , image 3 and Figure 4As shown, the outer peripheral surface of the cooling core 3 has helical and alternately arranged inflow cooling grooves 31 and return flow cooling grooves 32 , the cross sections of the inflow cooling grooves 31 and the return flow cooling grooves 32 are semicircular. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com