Flexible precise material frame

An accurate and flexible technology, applied in the field of fixtures, can solve the problem of poor repeatability of part positioning and achieve high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

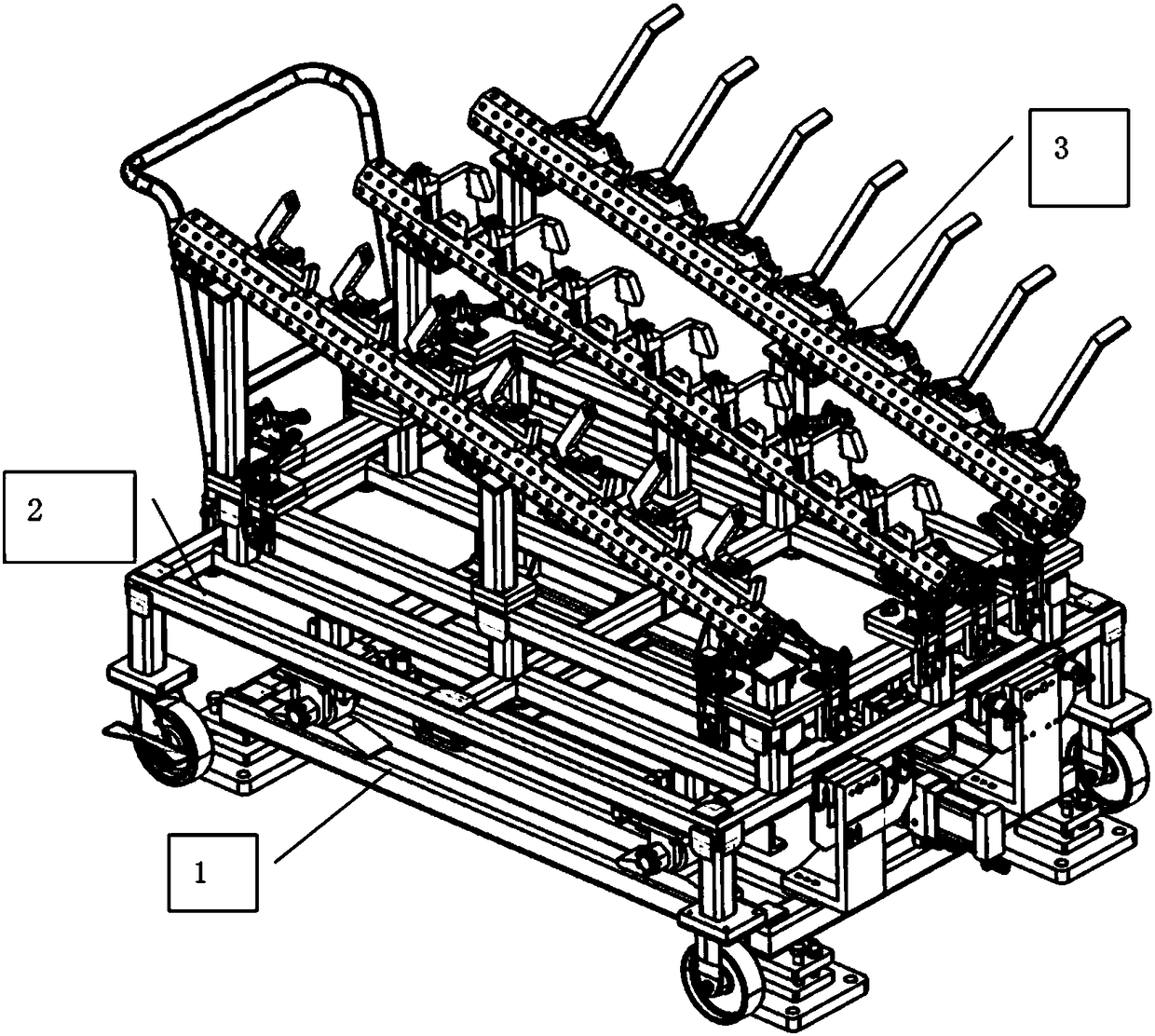

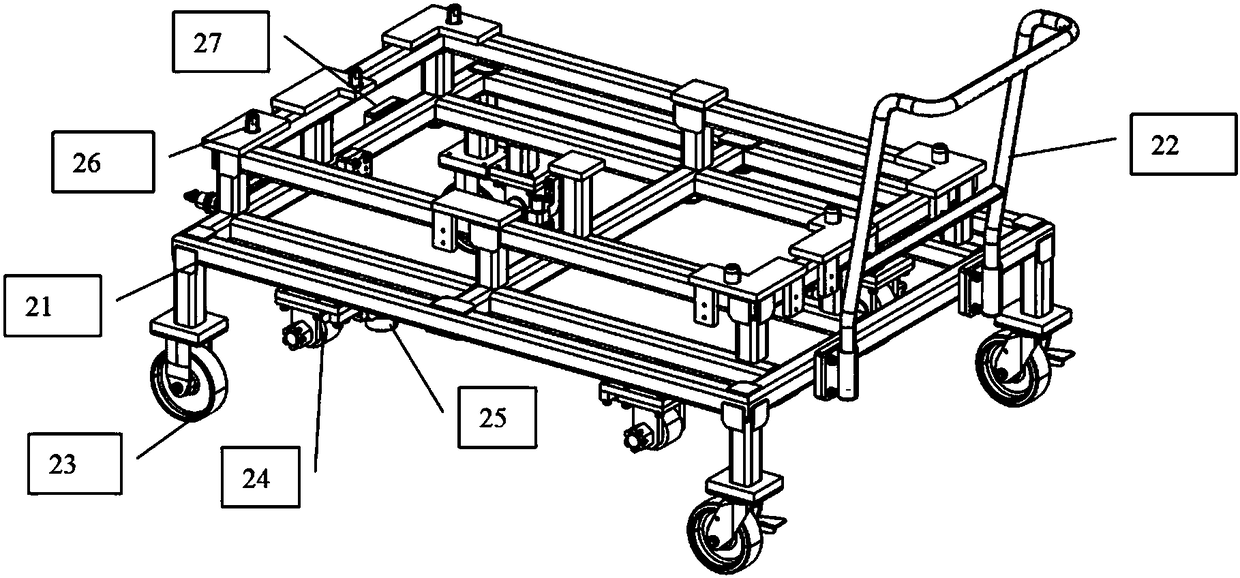

[0018] Such as Figure 1 to Figure 4 As shown, a kind of flexible and accurate material rack comprises a ground positioning mechanism 1, an accurate material rack vehicle 2 and a positioning flexible switching mechanism 3, and the positioning flexible switching mechanism 3 is arranged on the precise material rack vehicle 2, and the precise material rack The rack car 2 is positioned and docked with the ground positioning mechanism 1, and the precise material rack car 2 is a shared part, which is used to adapt to different vehicle models. Docking, parts positioning repeatability is high.

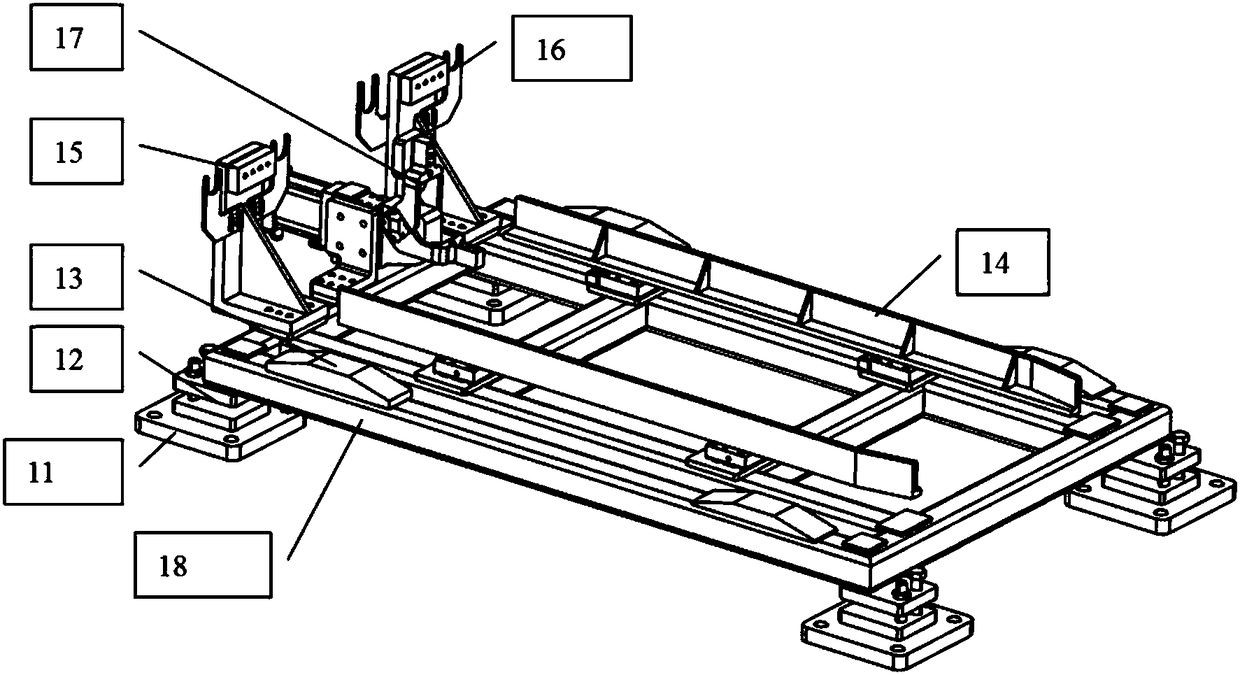

[0019] Such as Figure 1 to Figure 4 As shown, the ground positioning mechanism 1 includes a backing plate 11, a guide support seat 12, a ground positioning frame 18, a Z-direction support block 13 supporting the precision rack car 2 in the height direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com