Power head capable of adjusting cutter angle

A technology of tool angle and power head, applied in the field of power head, can solve the problems of difficult to improve machining accuracy, weak fixing effect, large oscillation force, etc., to reduce difficulty and assembly difficulty, small components and space occupied, and tolerance range Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

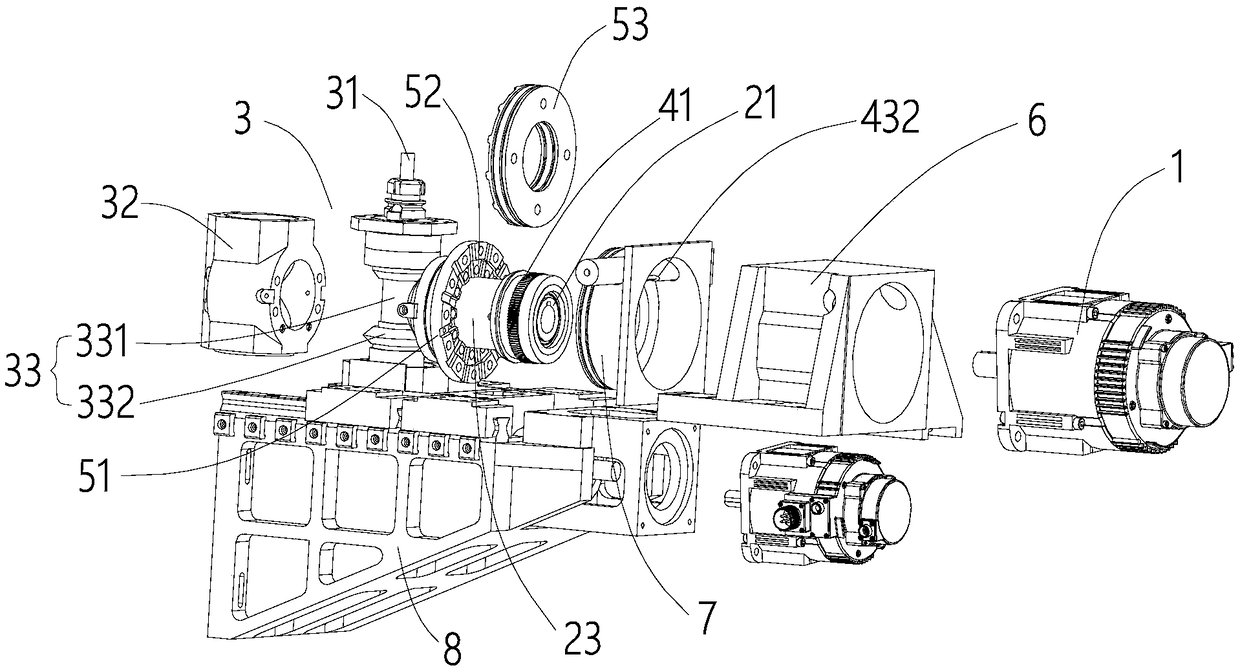

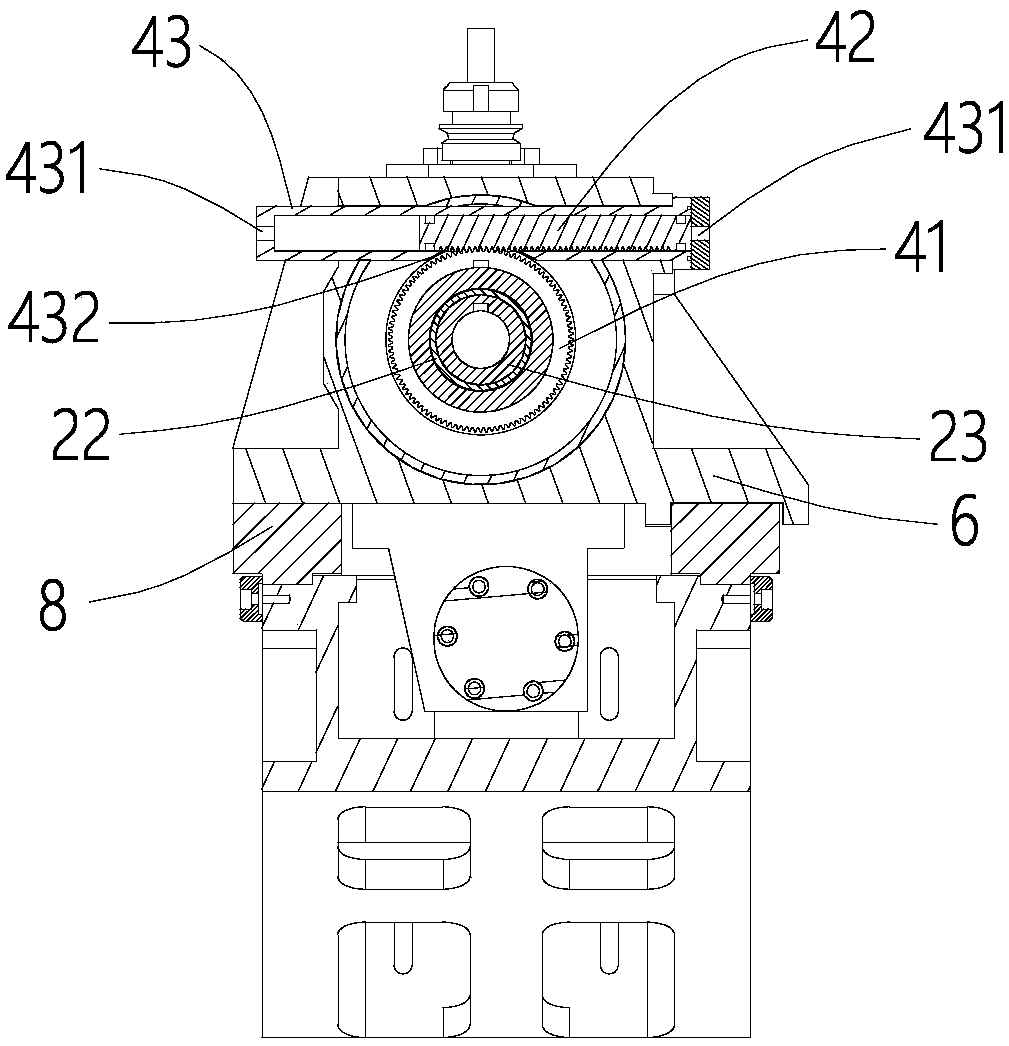

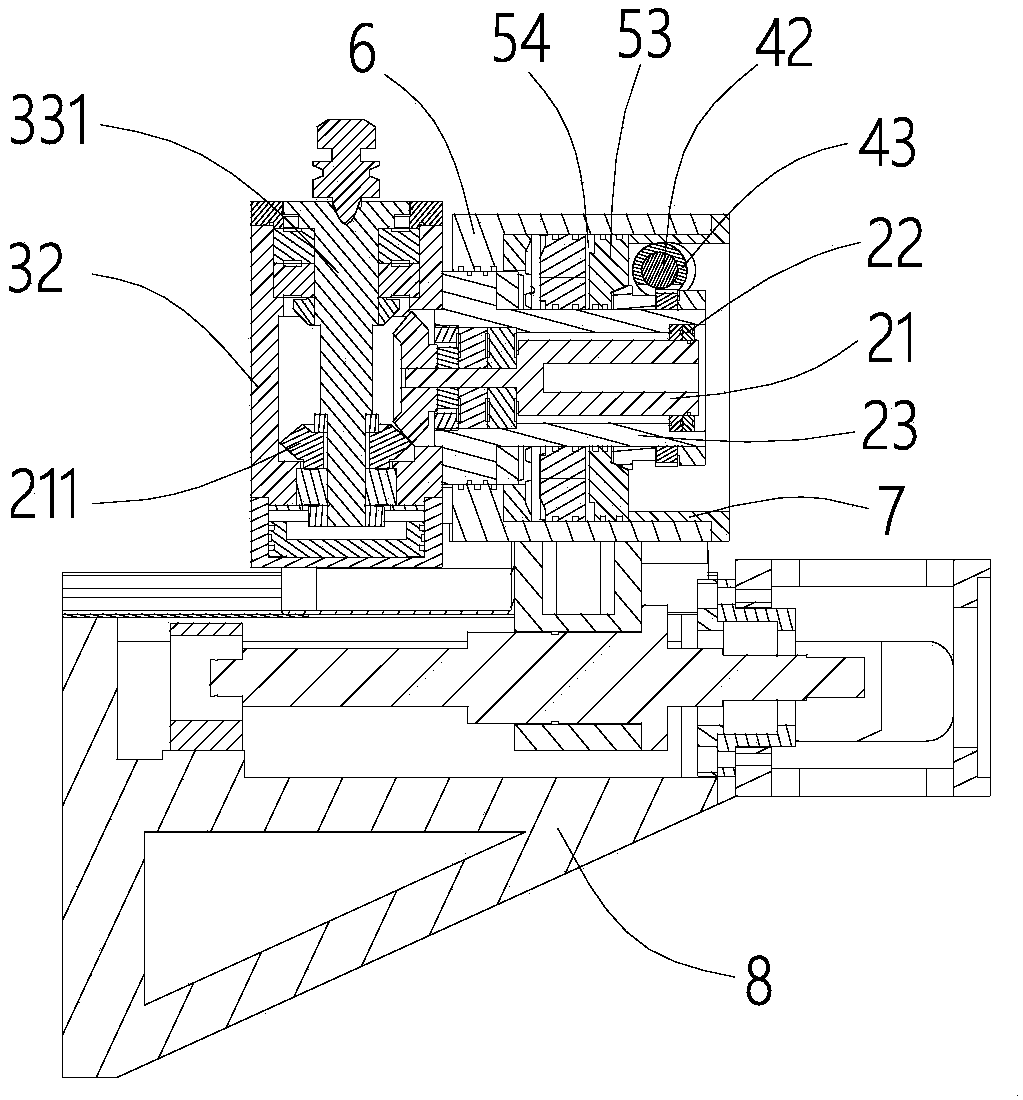

[0026] A kind of adjustable tool angle power head of the present invention is illustrated in conjunction with the accompanying drawings, as can be seen from the figure:

[0027] As embodiment 1 of the present invention, as attached Figure 1-3 Shown:

[0028] A power head capable of adjusting the angle of the cutter, comprising a first motor 1, a shaft assembly and a cutter 3, the first motor 1 is connected through the shaft assembly and drives the cutter head 31 of the cutter 3 to rotate;

[0029]The shaft assembly includes a main shaft 21, a bearing 22 and a shaft sleeve 23, the main shaft 21 and the tool 3 adopt space gear transmission, and the first motor 1 drives the cutter head 31 of the tool 3 to rotate through the main shaft 21 The bearing 22 supports the main shaft 21 to rotate in the bushing 23, and the bushing 23 is connected and fixed to the tool 3;

[0030] It also includes an indexing gear 41 and a rack 42, the indexing gear 41 and the rack 42 mesh with each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com