Straw crushing body and crushing returning apparatus with same

A technology of straw crushing and main body, which is applied in the field of agricultural machinery, can solve the problems of poor crushing effect, uneven spreading, and inability to crush and landfill corn straw in one step, and achieve the effects of uniform throwing, sufficient contact, and shortening the decay time of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

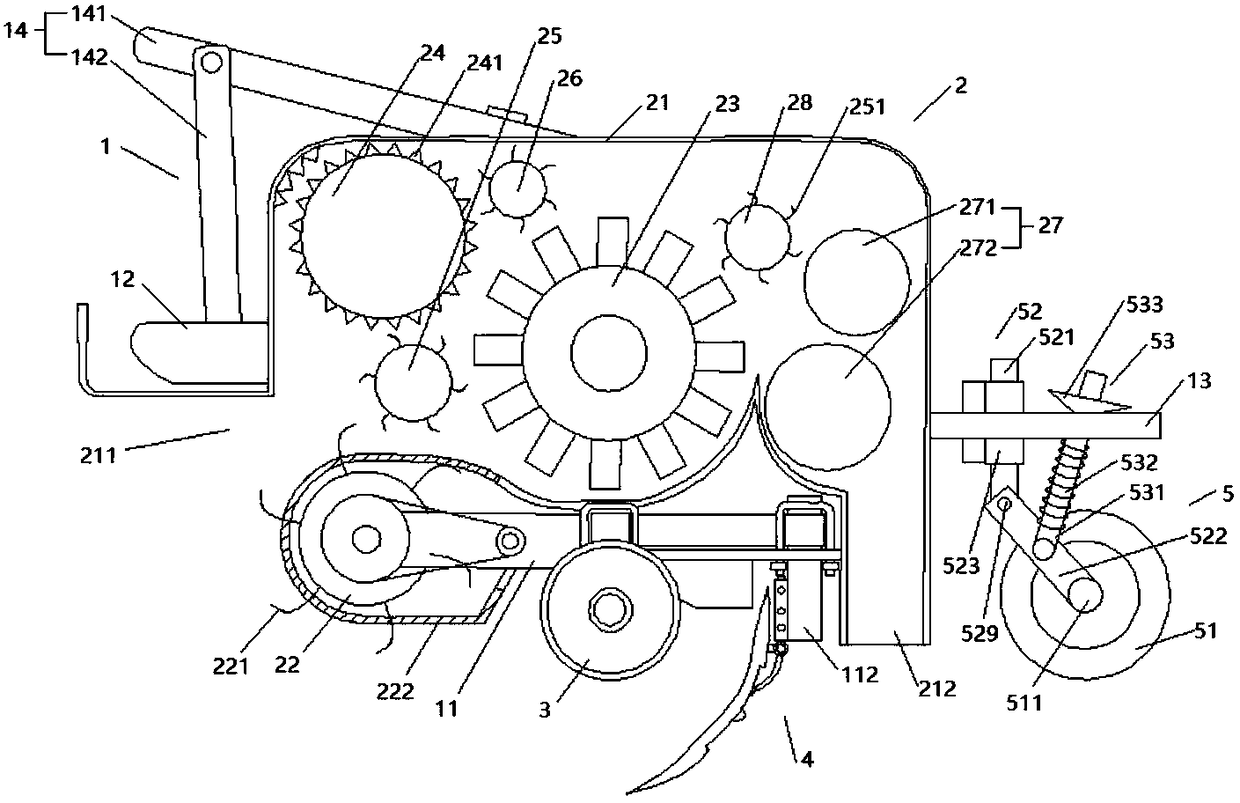

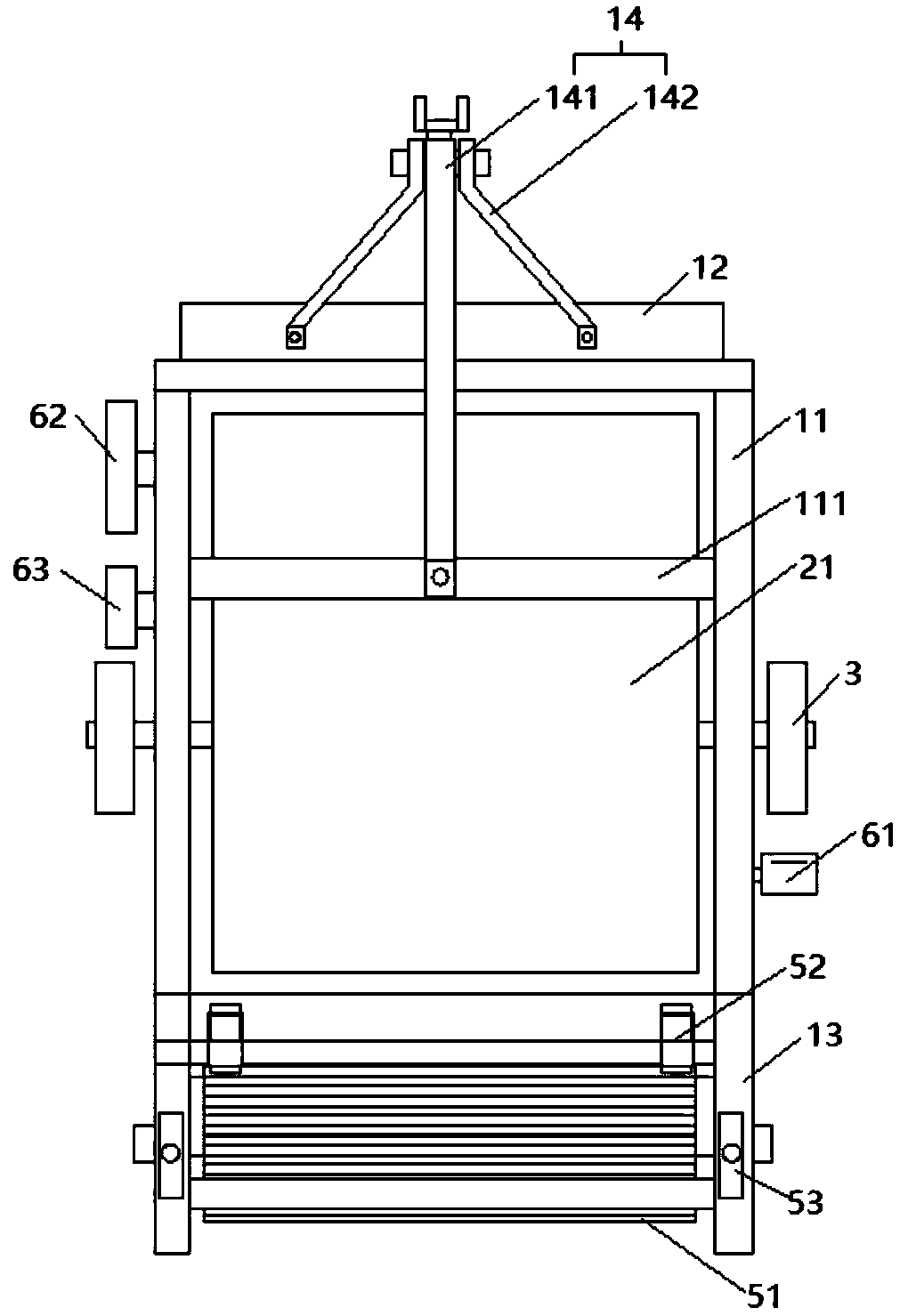

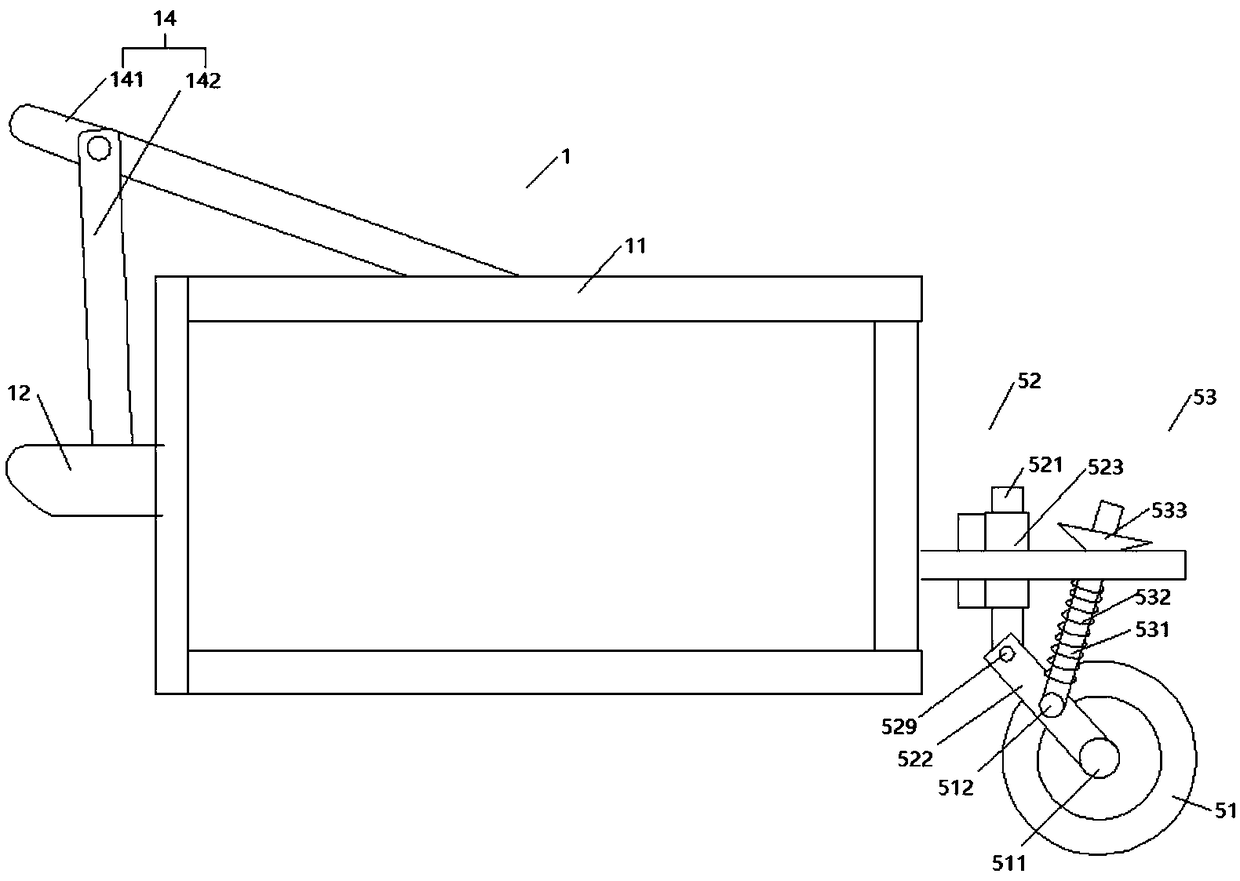

[0060] Such as Figure 1~3 As shown, the straw crushing and returning device includes a frame 1, a straw crushing main body 2, a walking device 3, a ditching device 4, and a soil suppression device 5. The frame 1 includes a rectangular parallelepiped frame body 11, a front support plate 12, and a rear support 13 and a traction bracket 14, the front support plate 12 is fixedly mounted on the front end of the cuboid frame body 11, the rear bracket 13 is fixedly mounted on the rear end of the cuboid frame body 11, and the traction bracket 14 includes a first Drawbar 141 and two second drawbars 142 positioned at both sides of the first drawbar 141; one end of the two second drawbars 142 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com