Special-shaped support equipment for ends of fully mechanized coal face

A fully mechanized working face, special-shaped technology, applied in mining equipment, earthwork drilling, mine roof support and other directions, can solve the problems of poor safety, low operation efficiency, safety accidents, etc., to achieve safe and reliable use, easy operation, support and movement stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

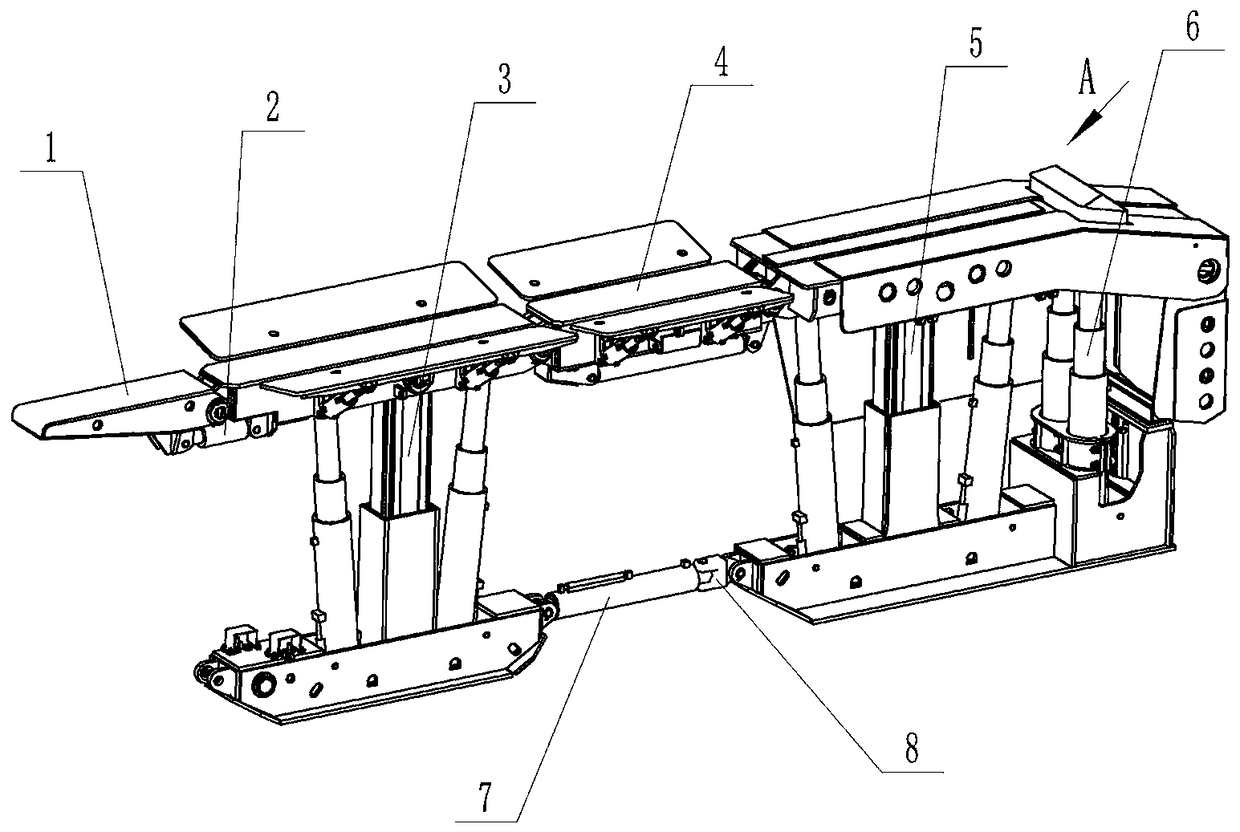

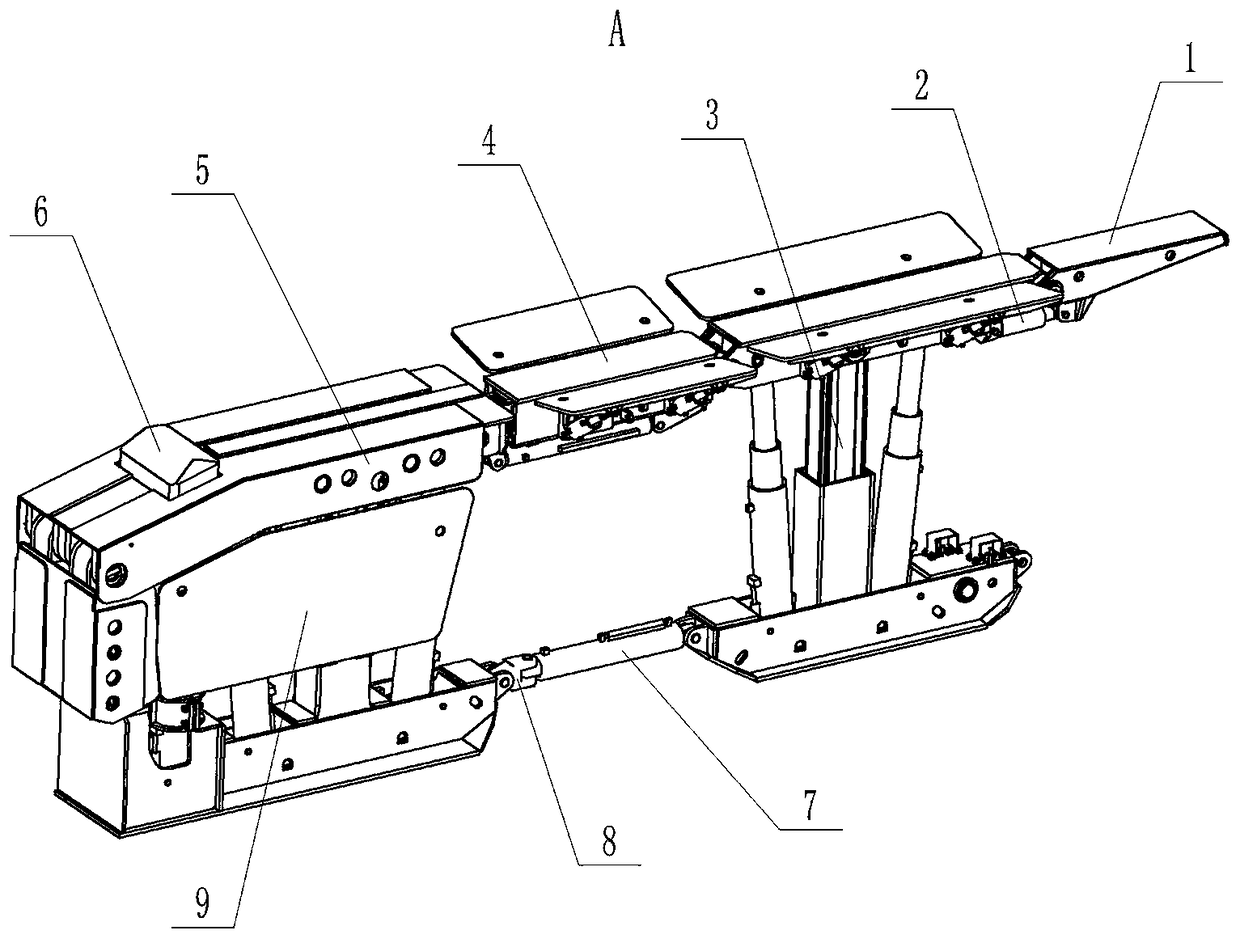

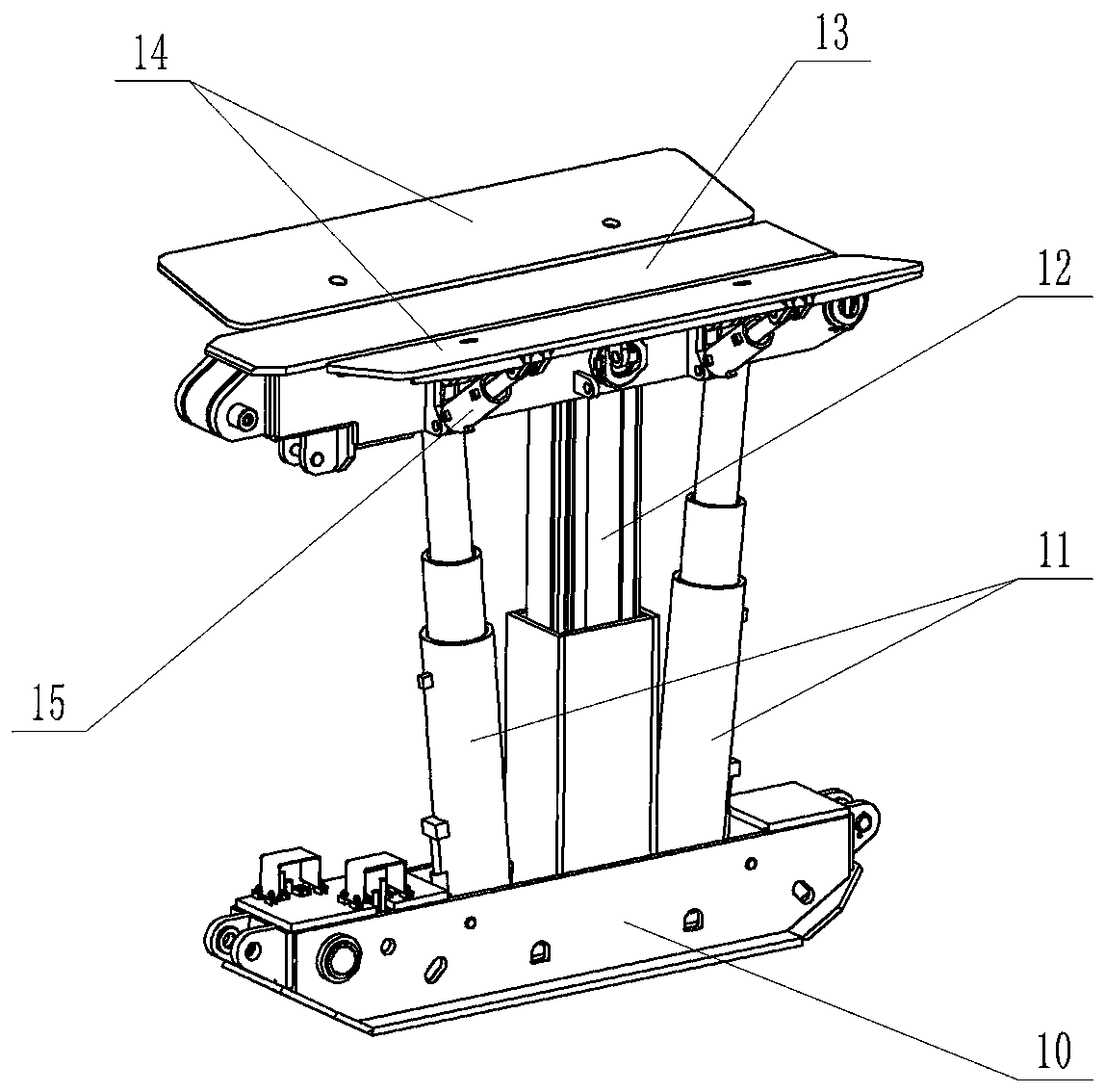

[0041] according to Figure 1-20 The specific structure of the present invention will be described in detail. The special-shaped support equipment at the end of the fully mechanized mining face includes a front support bracket 3 for preventing convergence and deformation of the roadway. The front support bracket 3 is composed of a front support base 10 and a front support top beam 13 . The middle part of the support base main body 16 of the front support base 10 is provided with a support guide sleeve 19 arranged vertically upward; The column socket 18 at the bottom of the column that is connected with the fixed cylinder bottom of the hydraulic column. The rear part of the support base main body 16 of the front support base 10 is provided with a pulling end 17 hinged with the frame-moving hydraulic cylinder 7; the front part of the support base main body 16 is provided with a reserved connection end 21 and a vertical Auxiliary lifting mechanism 20 arranged straight down. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com