Dual-plate-type die closing unit used for moulding machine

A molding machine and molding die technology, applied in the field of double-plate clamping unit, can solve the problems of increasing the structural length of the clamping unit and the limited change in length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

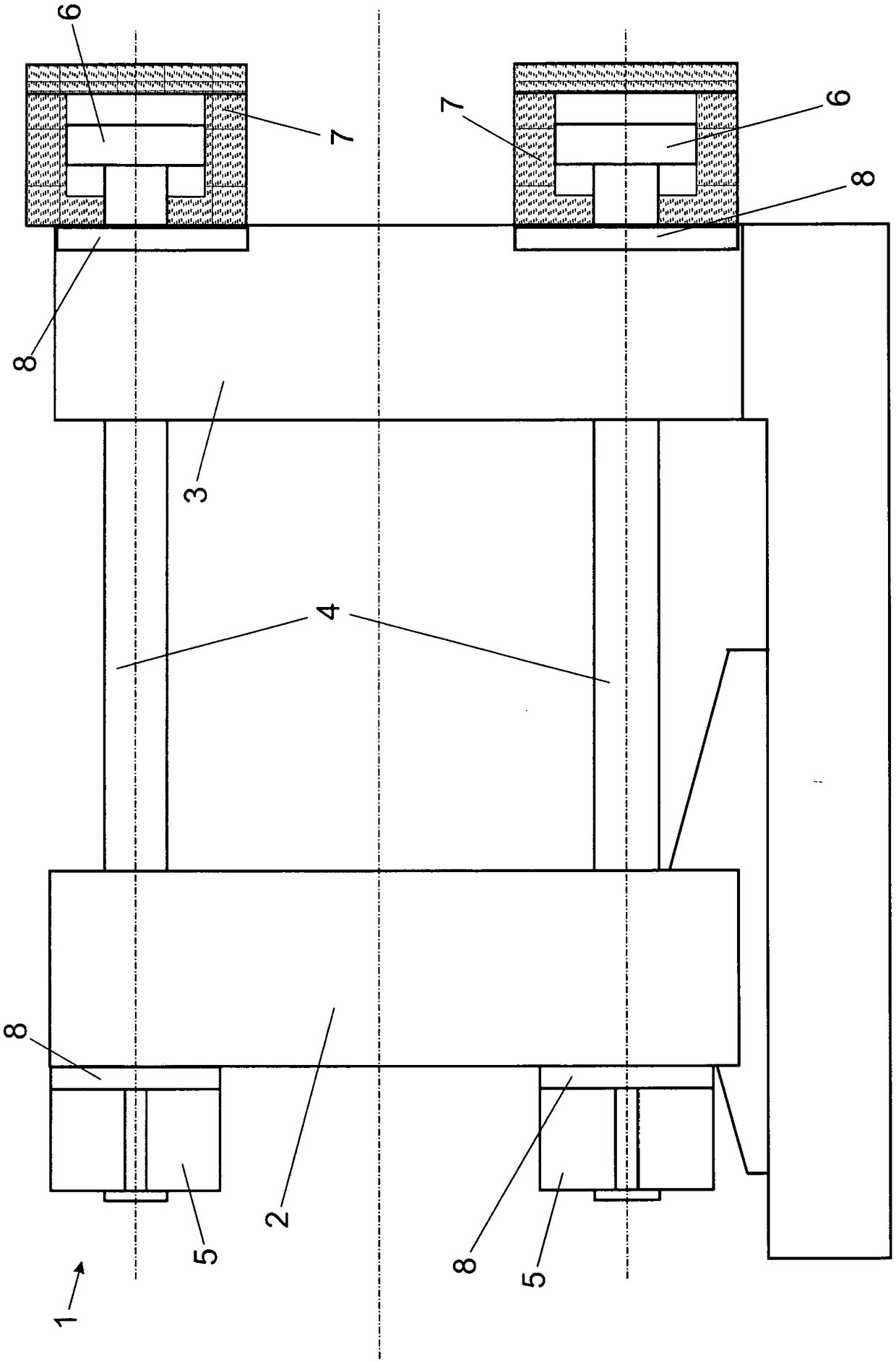

[0033] exist figure 1 The molding machine (in this case an injection molding machine) according to the invention shown in has a movable first mold clamping plate 2 and a fixed second mold clamping plate in the region of the double-platen clamping unit 1 3. Two mold clamping plates 2 and 3 are penetrated by four tie rods 4 . The tie rod 4 is mounted movably both relative to the first mold clamping plate 2 and also relative to the second mold clamping plate 3 .

[0034] Each locking device 5 is used for locking the pull rod 4 and the first mold clamping plate 2 . The locking devices 5 are each configured as split nuts. The inner contour of the split nut cooperates with the outer contour on the rod 4 in the closed state of the nut, thereby realizing the locking of the rod 4 and the first mold clamping plate 2 .

[0035] Piston-cylinder units 6 , 7 are arranged on the side of the second mold clamping plate 3 facing away from the first mold clamping plate 2 . The cylinders 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com