Multifunctional piston-cylinder sleeve system friction-wear experiment testing machine

A friction and wear test, piston-cylinder liner technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of low test accuracy of the power test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Introduce technical scheme of the present invention below in conjunction with accompanying drawing:

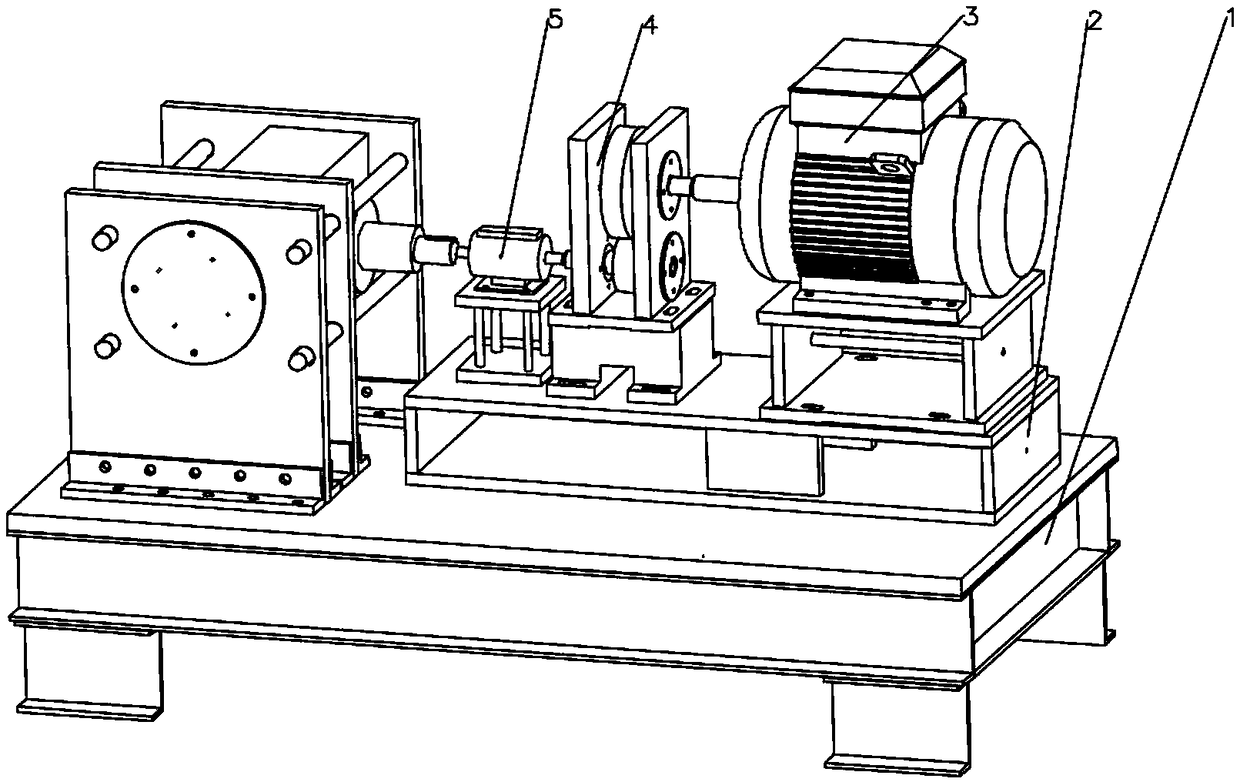

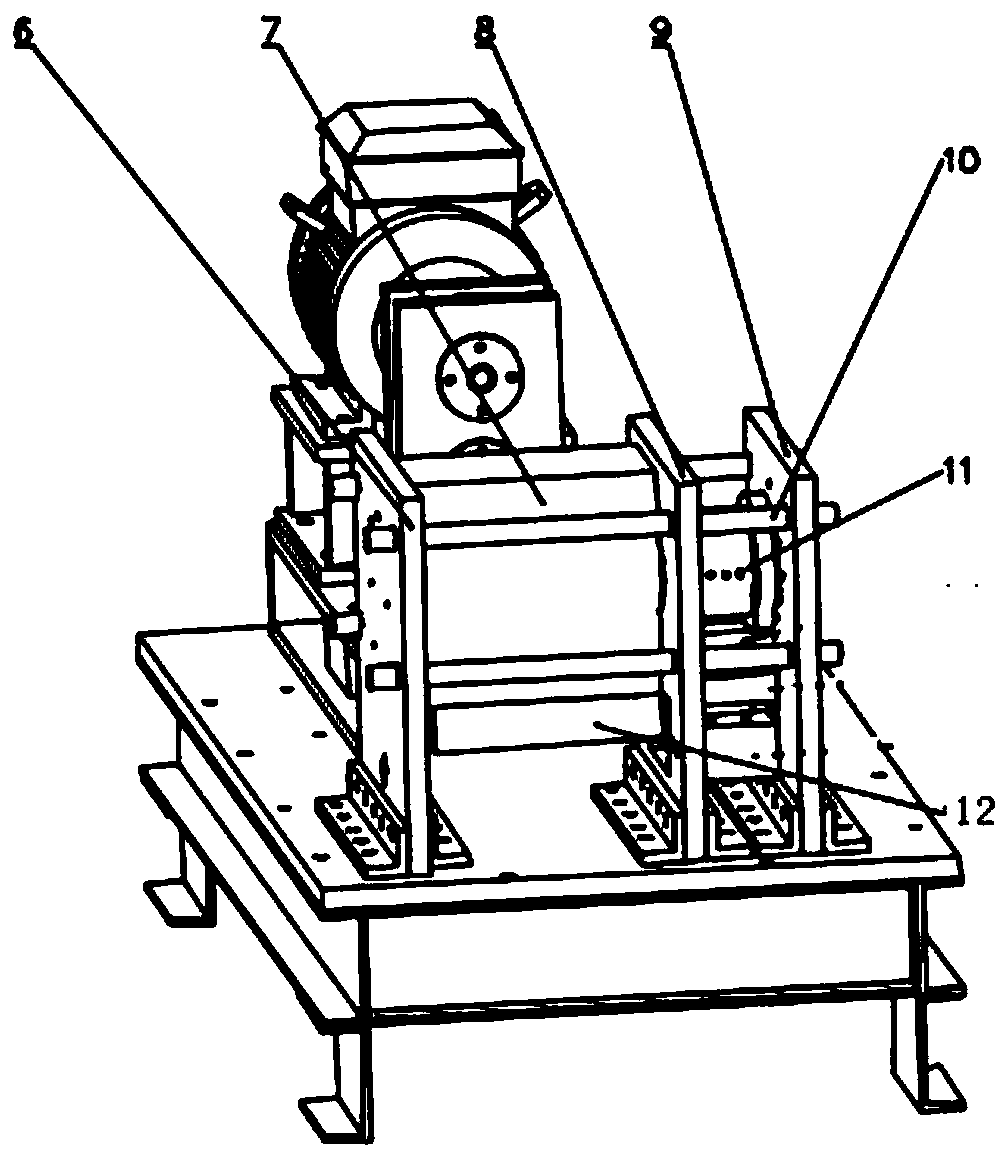

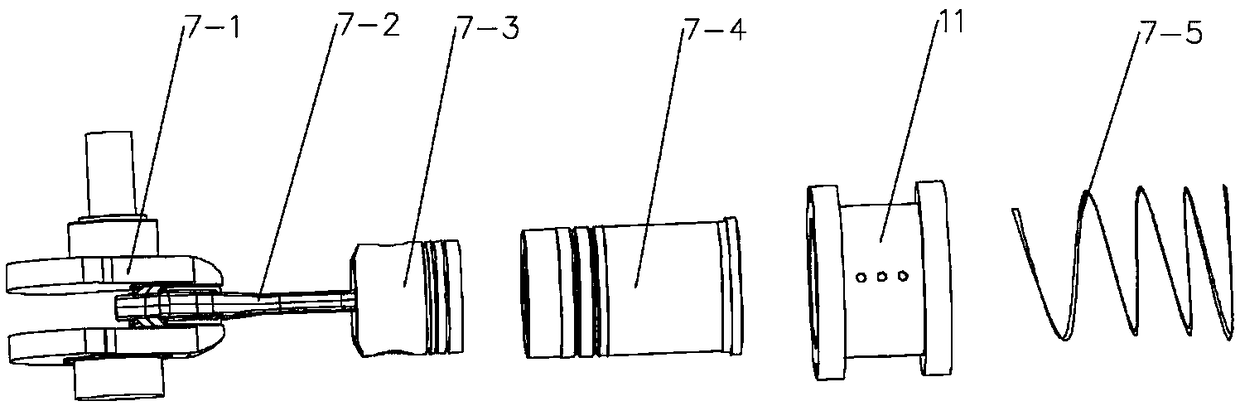

[0031] A multifunctional piston-cylinder liner system friction and wear tester, comprising a tester support 1, a power part support 2, a frequency conversion speed regulation motor 3, a transmission 4, a torque speed tester 5, and a tester support mechanism; The partial bracket 2 is fixed on the testing machine bracket 1 adjacent to the supporting mechanism of the testing machine; the variable frequency speed adjustable motor 3, the transmission 4 and the torque speed tester 5 are successively fixed adjacently on the power part bracket 2; the variable frequency speed adjustable motor 3 Connect with the input end of the transmission 4 through an elastic coupling, the output end of the transmission 4 is connected with the torque speed tester 5 through the elastic coupling, and the piston crank linkage mechanism 7 of the testing machine is connected with the torque speed te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com