Device and method for conducting vibration monitoring and fault early warning on centrifugal pump

A fault early warning and vibration monitoring technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as unit failure and scrapping, and achieve the effects of fast running speed, accurate evaluation results and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

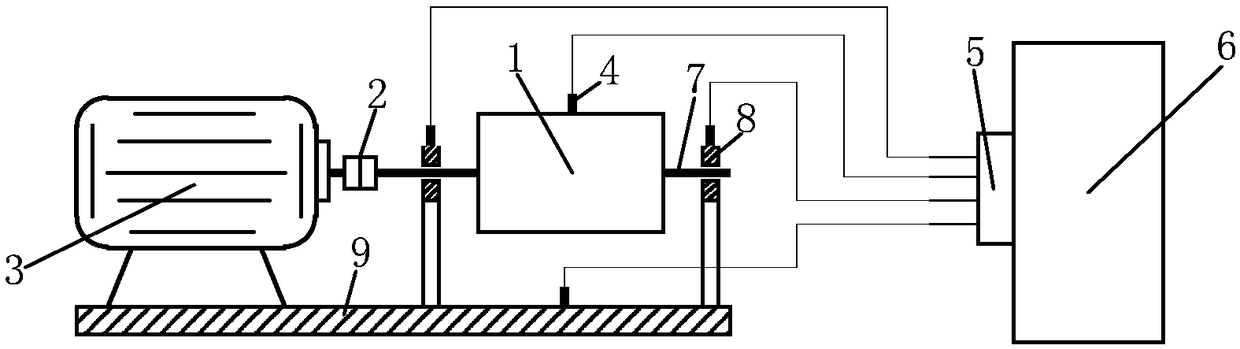

[0042] The inventive device such as figure 1 As shown, it includes a centrifugal pump body 1, a shaft coupling 2, a motor 3, a vibration sensor 4, a data acquisition card 5 and a processing host computer 6; a rotating shaft 7 is installed in the centrifugal pump body 1, and the two ends of the rotating shaft 7 are The rolling bearing 8 is supported, and the rotating shaft 7 is connected to the motor 3 through the shaft coupling 2; the vibration sensor 4 is connected to the data acquisition card 5, and the data acquisition card 5 is connected to the processing host computer 6. Among them, the vibration sensor 4 is the ULT2004V uniaxial IEPE piezoelectric acceleration sensor of Kangtai Electronics; the data acquisition card 5 is the PCIE-1816 multi-function card of Advantech.

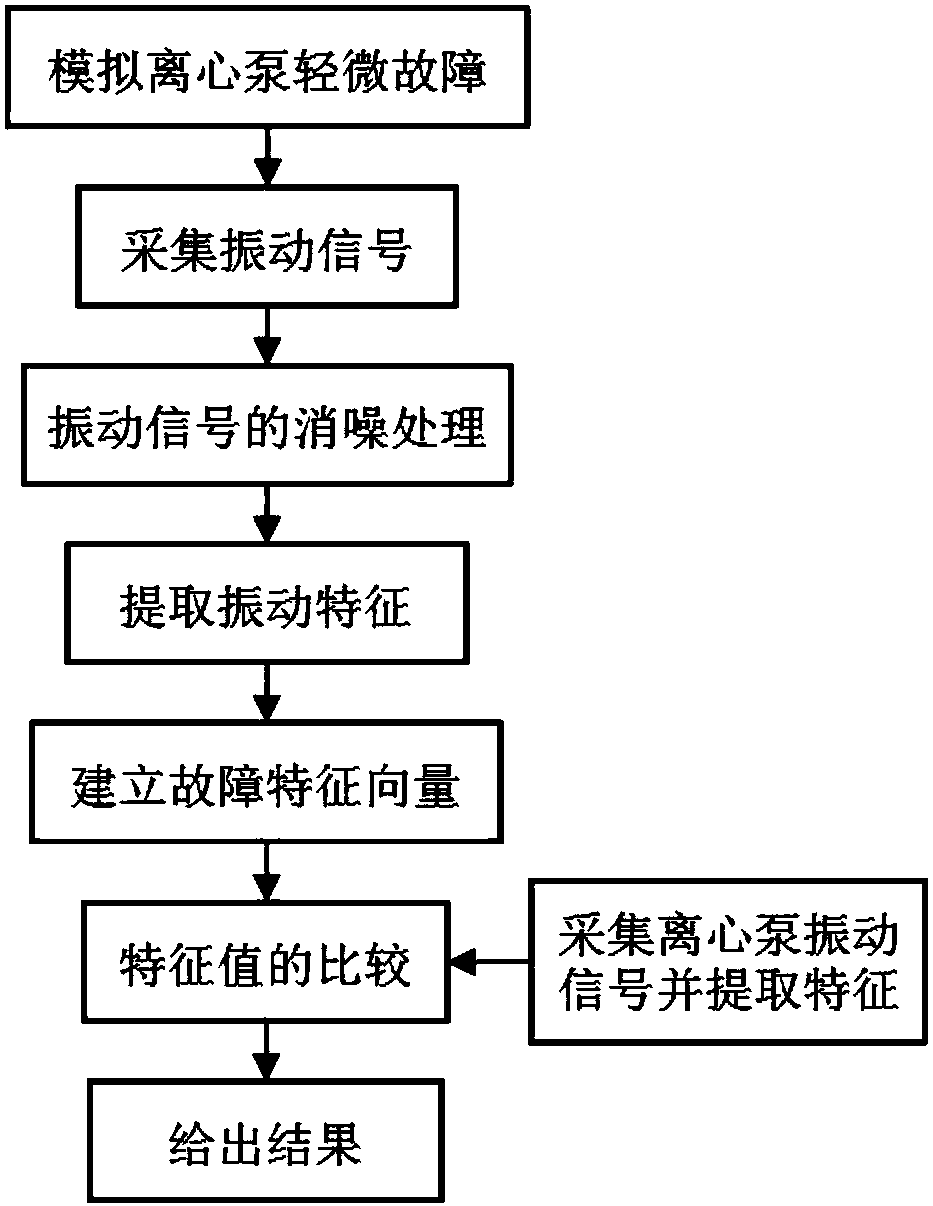

[0043] according to figure 2 The flow of the method shown is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com