A kind of spring and autumn antistatic women's clothing and its production process

An anti-static, women's clothing technology, applied in the field of clothing, can solve problems such as affecting clothing production, affecting clothing styling, etc., to achieve the effect of comfortable and healthy wearing, keeping dry, and feeling smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

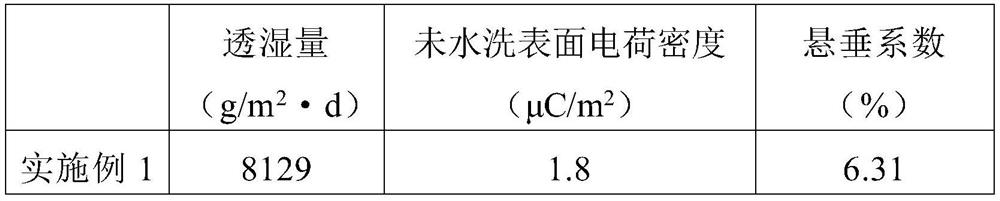

Embodiment 1

[0039] The spring and autumn antistatic women's clothing is made of antistatic fabric.

[0040] The preparation method of described antistatic fabric, comprises the steps:

[0041] (1) Add 6.5 parts by weight of white latex, 8 parts by weight of ethanol, 1 part by weight of citric acid, 3 parts by weight of functionalized titanium dioxide, and 3.9 parts by weight of surfactant into 80 parts by weight of deionized water and stir for 20 minutes at a speed of 300r / min. Obtain the finishing solution evenly;

[0042] (2) Immerse the fabric in the finishing liquid for 20 minutes, then squeeze the impregnated fabric to a margin of 70 wt%, and dry it to obtain the antistatic fabric.

[0043] The surfactant in the step (1) is dodecyloxyethyl-α-D-xylopyranoside.

[0044] The dipping temperature in the step (2) is 40° C., and the mass ratio of the fabric to the finishing liquid is 1:10.

[0045] The drying temperature in the step (2) is 75° C., and the drying time is 6 hours.

[0046...

Embodiment 2

[0049] The spring and autumn antistatic women's clothing is made of antistatic fabric.

[0050] The preparation method of described antistatic fabric, comprises the steps:

[0051] (1) Add 6.5 parts by weight of white latex, 8 parts by weight of ethanol, 1 part by weight of citric acid, 3 parts by weight of titanium dioxide, and 3.9 parts by weight of surfactant into 80 parts by weight of deionized water and stir at a speed of 300r / min for 20min to obtain Finishing solution;

[0052] (2) Immerse the fabric in the finishing liquid for 20 minutes, then squeeze the impregnated fabric to a margin of 70 wt%, and dry it to obtain the antistatic fabric.

[0053] The surfactant in the step (1) is dodecyloxyethyl-α-D-xylopyranoside.

[0054] The dipping temperature in the step (2) is 40° C., and the mass ratio of the fabric to the finishing liquid is 1:10.

[0055] The drying temperature in the step (2) is 75° C., and the drying time is 6 hours.

[0056] The production process of t...

Embodiment 3

[0058] The spring and autumn antistatic women's clothing is made of antistatic fabric.

[0059] The preparation method of described antistatic fabric, comprises the steps:

[0060] (1) Add 6.5 parts by weight of white latex, 8 parts by weight of ethanol, 1 part by weight of citric acid, 3 parts by weight of functionalized titanium dioxide, and 3.9 parts by weight of surfactant into 80 parts by weight of deionized water and stir for 20 minutes at a speed of 300 r / min. Uniformly obtain the finishing solution;

[0061] (2) Immerse the fabric in the finishing liquid for 20 minutes, then squeeze the impregnated fabric to a margin of 70 wt%, and dry it to obtain the antistatic fabric.

[0062] Surfactant is sodium lauryl sulfate in the described step (1).

[0063] The dipping temperature in the step (2) is 40° C., and the mass ratio of the fabric to the finishing liquid is 1:10.

[0064] The drying temperature in the step (2) is 75° C., and the drying time is 6 hours.

[0065] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com