Mask as well as manufacturing method and evaporation method thereof

A mask and evaporation technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of metal mask wrinkles and other problems, to avoid wrinkles accumulation, reduce friction coefficient, avoid the effect of folds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

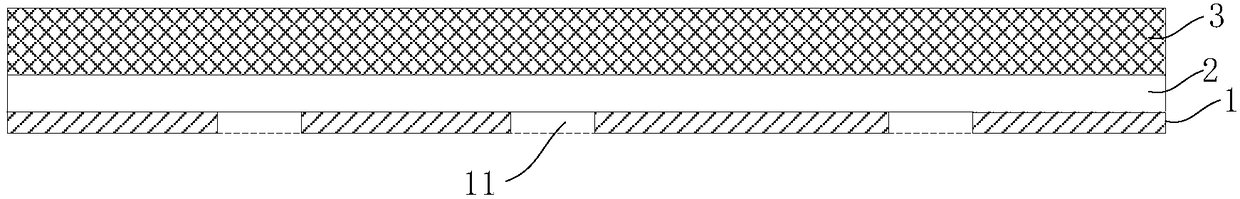

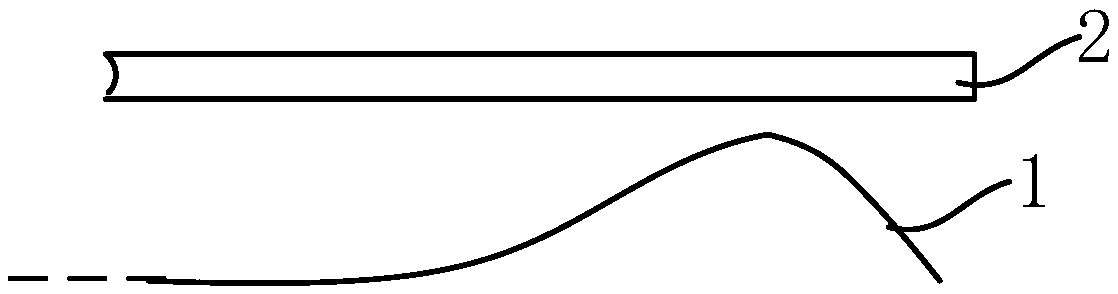

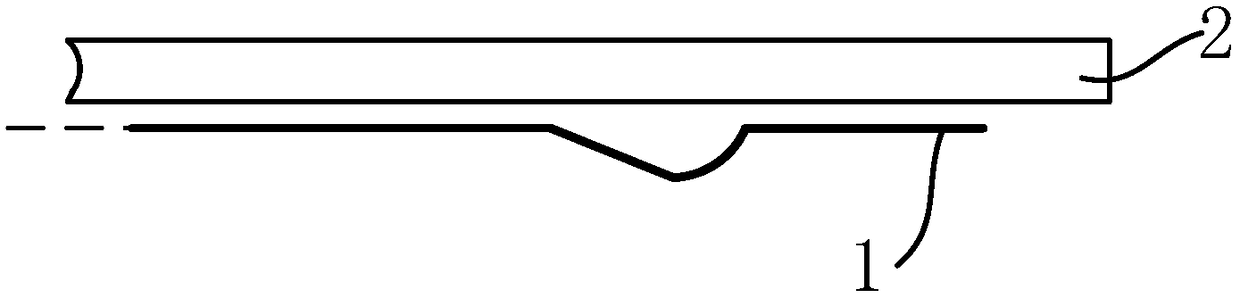

[0049]In order to solve the problem that the metal mask is prone to wrinkles, an embodiment of the present invention provides a mask, by providing a groove at the edge of the mask body, and filling the groove with a material that cannot be absorbed by a magnet. Magnetic isolation layer, when the mask plate is applied to the substrate in the evaporation equipment, the distance between the mask plate body at the edge and the magnet element used to generate the magnetic field is increased to reduce the distance at the edge Magnetic adsorption, so that the folds in the opening area can smoothly expand to the edge, avoiding the accumulation of folds, so as to avoid the problem of mask folds.

[0050] combine Figure 4 and Figure 5 As shown, the mask plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com