Vehicle drive train and method for operating a drive train

A technology of power train and vehicle, applied in the field of vehicle power train, can solve problems such as hindering the overall efficiency of the power train of the vehicle, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

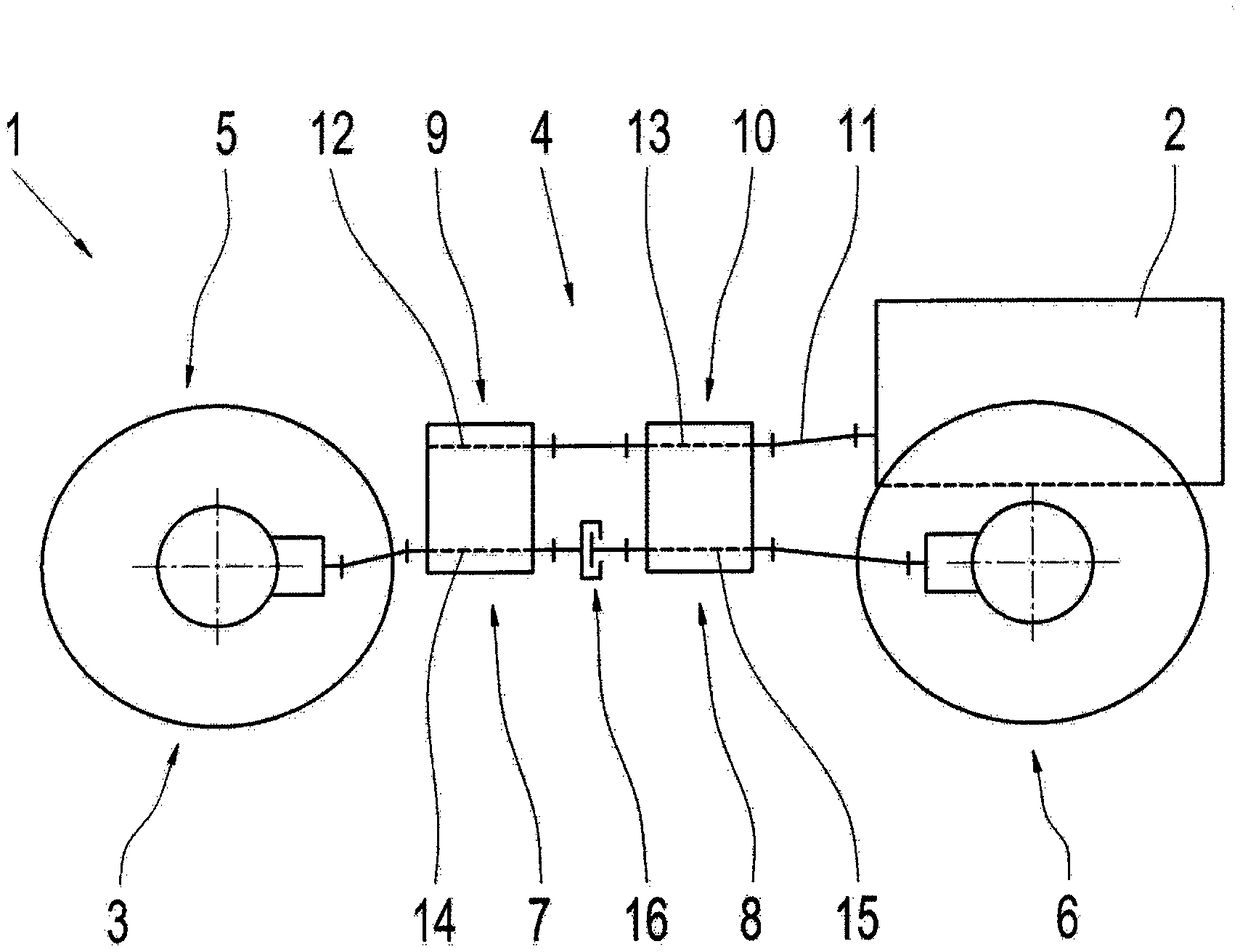

[0030] figure 1 A vehicle drive train 1 is shown in FIG. 1 with a drive machine arrangement 2 , an output mechanism 3 and a transmission arrangement 4 arranged in the power flow between the drive engine arrangement 2 and the output mechanism 3 . The drive engine arrangement 2 is in the present case designed as an internal combustion engine, preferably as a diesel internal combustion engine. Furthermore, it is also possible for the drive engine arrangement 2 to comprise a combination of an internal combustion engine and an electric machine or a plurality of internal combustion engines and / or electric machines in order to be able to provide the respectively required tractive force in the region of the output mechanism 3 . Furthermore, it is also possible for the drive machine arrangement 2 to have one or more electric motors.

[0031] The output mechanism 3 in turn comprises two drivable axles 5 , 6 , wherein the axle 5 is in the present case the vehicle front axle of the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com