Device for manufacturing circuit through liner plate engraving process

A liner and circuit technology is applied in the field of devices for making circuits by the liner engraving method, and can solve the problems of inability to adapt to low cost, high efficiency, complicated manufacturing process, small size and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

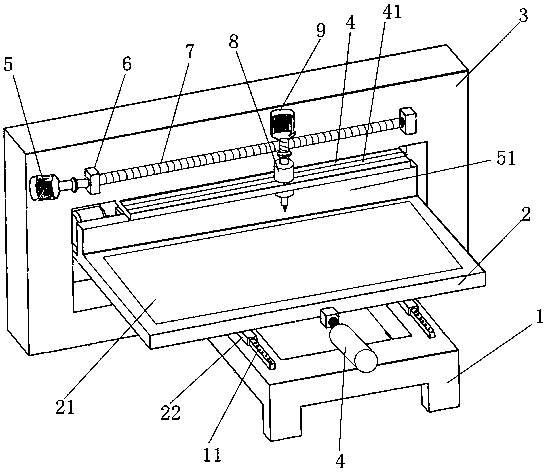

[0017] like figure 1 As shown, the present invention provides a device for making a circuit by lining board engraving method. The device includes a frame 1 as a supporting device. The frame 1 is provided with a stand 2 on which a backing board twenty one. The platform 2 is connected to the frame 1 through the first driving device 4, the driving end of the first driving device 4 is connected to the platform 2, and the platform 2 can move relative to the frame 1 under the action of the first driving device 4 .

[0018] like figure 1 As shown, a slide rail 11 is provided on the frame 1, and a track 22 is provided on the frame 2, and the slide rail 22 is connected with the slide rail 11 to realize the sliding connection between the frame 2 and the frame 1. When the first driving device 4 drives the platform 2 to move, the platform 2 drives the slideway 22 to slide relative to the slide rail 11 .

[0019] The frame 1 is provided with a mounting frame 3, the mounting frame 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com