Vibration discharging device of elastic sheet input machine for voice coil motor

A technology of voice coil motor and shrapnel, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving yield rate, ingenious design, and improving vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

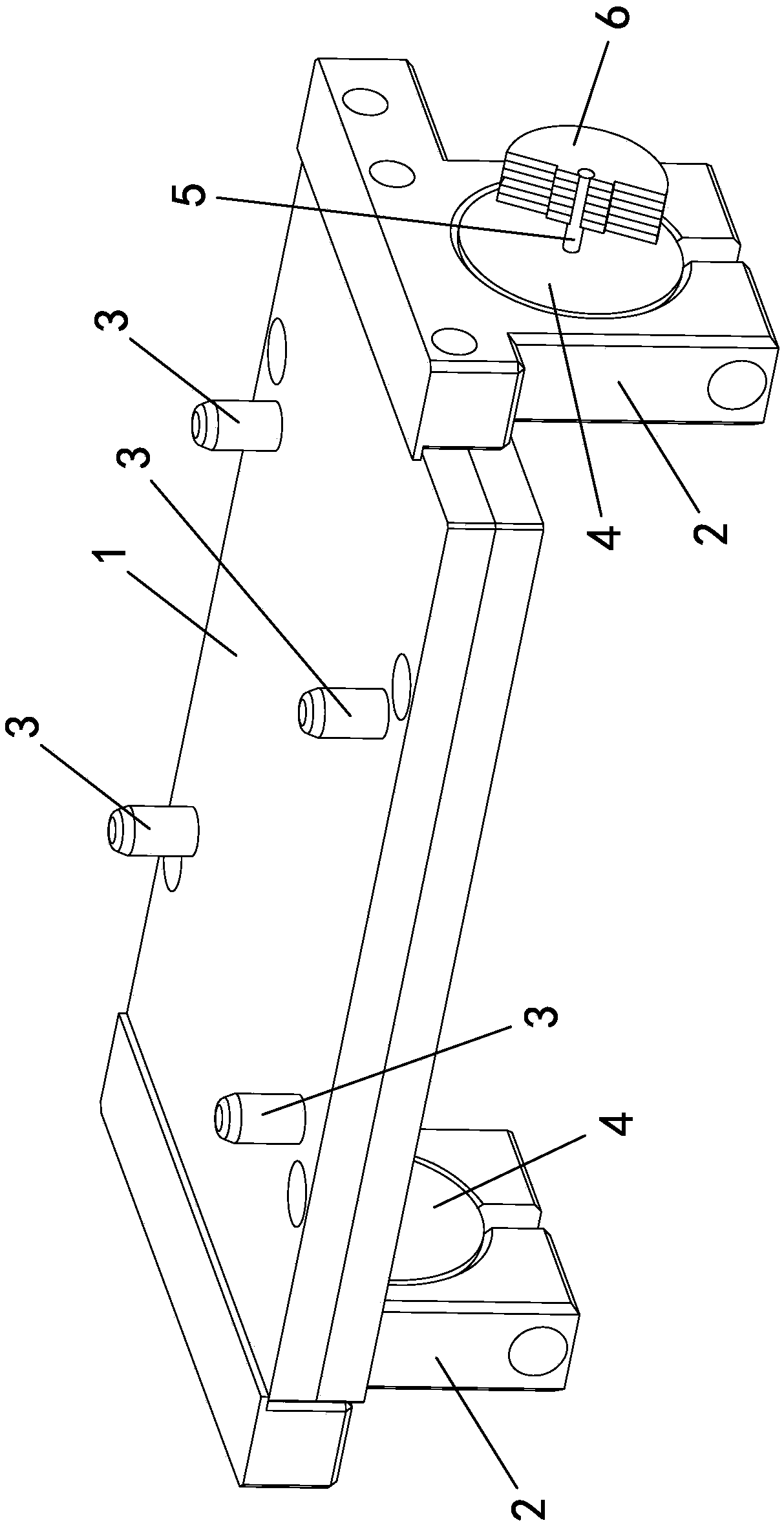

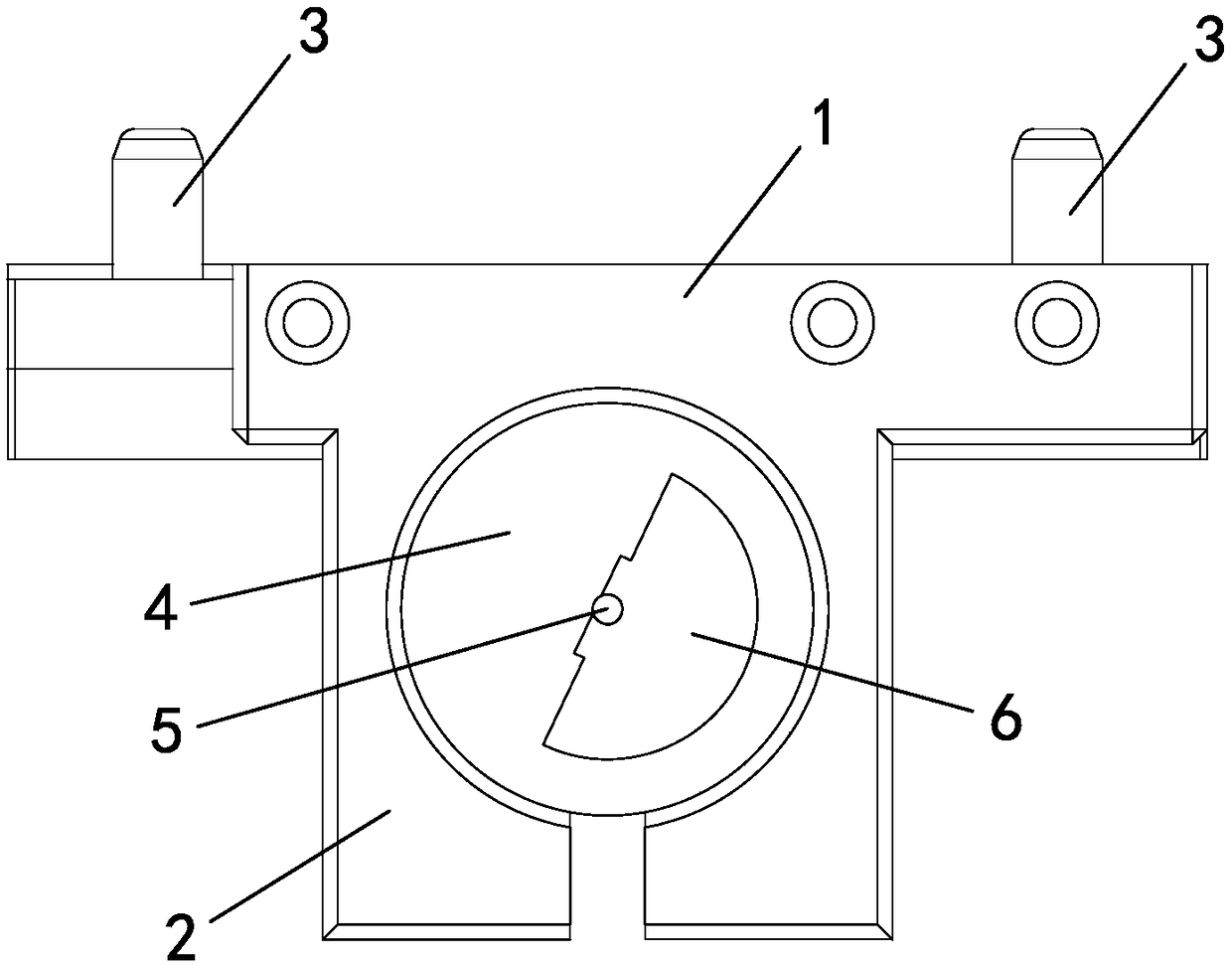

[0022] Example: see attached figure 1 , 2 As shown, a vibrating discharge device of a voice coil motor shrapnel inserting machine is set in a voice coil motor shrapnel inserting machine (not shown in the figure), and is set in transmission with the material tray in the shrapnel inserting machine. The material tray is used to carry the carrier and shrapnel of the stacked and aligned voice coil motors.

[0023] The device includes a frame body, which is composed of a top plate 1 and two side plates 2; the top plate 1 is arranged horizontally for carrying the material tray (not shown in the figure); the two sides The plates 2 are arranged vertically, and one left and one right are respectively fixed on both sides of the top plate 1; wherein, the top plate 1 is provided with at least three guide posts 3 protruding upward, and each guide post 3 is perpendicular to the The top plate 1 and each of the guide columns 3 are set in alignment with several guide holes at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com