Method for reducing emission by reverse flotation reagent for carnallite mine

A carnalite ore and reverse flotation technology, applied in flotation, solid separation and other directions, can solve the problems of low content, large amount of mother liquor, poor separation and recovery technology and economic efficiency, and achieve the effect of good quality and environmental protection

Active Publication Date: 2018-08-03

青海省化工设计研究院有限公司

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

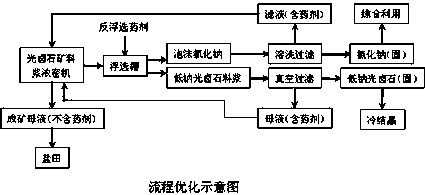

[0005] The invention aims at the characteristics of dodecylmorpholine refractory degradation, large amount of mother liquor and low content (ppm level), poor separation and recovery technology and economic efficiency, combined with the reverse flotation-cold crystallization process characteristics of carnallite ore to produce potassium chloride , using the process optimization method to achieve the purpose of reducing emissions, solving environmental impacts, and realizing fine control of flotation operation selection indicators, etc., providing a method for reducing emissions of reverse flotation agents for carnallite mines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0023] Example: The raw materials used in this case are all from the production materials of an enterprise

[0024] Carnallite raw ore composition:

[0025]

[0026] Composition of ore-forming brine (20°C):

[0027]

[0028] Reverse flotation reagent dodecylmorpholine content (%): 90%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of mineral flotation. A method for reducing emission by a reverse flotation reagent for a carnallite mine is characterized by comprising the following main steps that (1) a foam sodium chloride solution washing and filtering technology is added after reverse flotation operation, filtered filtrate containing medicament returns to a carnallite slurry thickener workshop section; (2) after the reverse flotation operation, the low sodium carnallite slurry is filtered in vacuum and the filtrate containing the medicament returns to the carnallite slurry thickener workshop section as well; and (3) the filtrate containing the medicament continuously returns to the carnallite slurry thickener workshop section for recycling, and finally, ore-forming mother liquor which does not contain the medicament returns to a salt pan. Combined the process characteristics of an original technology, the method adopts a process optimization method and adds a recycling technology of mother liquor containing medicament to replace the ore-forming mother liquor, the aims of reducing the emission by the reverse flotation reagent and reducing the environmental impact are achieved, and meanwhile, fine control of a flotation operation separating index can be realized.

Description

technical field [0001] The invention relates to the field of mineral flotation, in particular to a method for reducing discharge of potassium chloride reverse flotation agents. Background technique [0002] As we all know, mineral processing generally uses collectors, foaming agents, auxiliary agents, etc. to carry out bubbling flotation separation to achieve the purpose of enriching useful minerals. Flotation separation methods include forward flotation, reverse flotation and combination of forward and reverse flotation. This method has the characteristics of simplicity, economy, and easy scale-up, but there are also problems such as the flotation medium or mother liquor contains a large amount of surfactant, and it is difficult to separate, recover, and degrade. With the continuous development of economy and society, this kind of problem has become prominent, and it is an environmental protection problem that needs to be solved urgently in front of mineral processing ente...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B03D1/12

CPCB03D1/12

Inventor 唐宏学郭会宾王文侠刘海刚

Owner 青海省化工设计研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com