Tubular heating device

A technology of heating device and heating jacket, applied in the field of fire extinguishing system, can solve the problems of prolonging time, damage to inner lining, increasing energy consumption of fire extinguishing agent, etc., and achieves the effect of large heating jacket area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

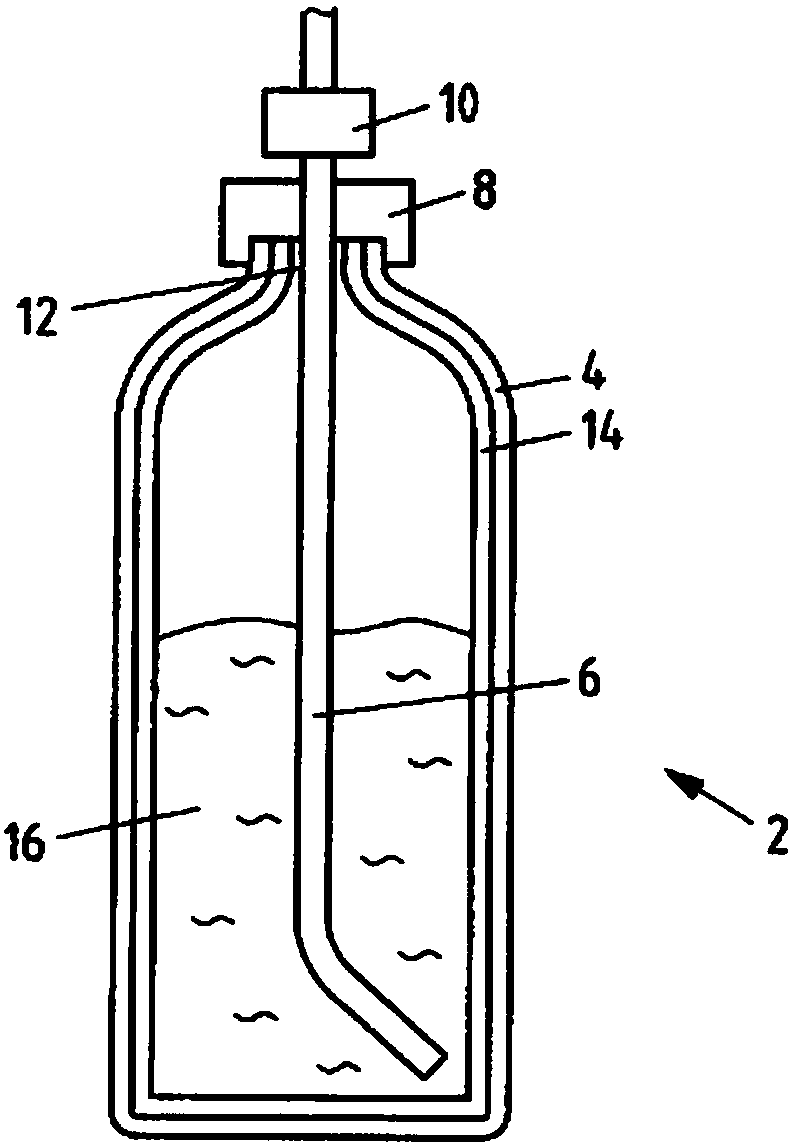

[0063] figure 1 A fire extinguishing system 2 with an extinguishing agent container 4 is shown. Arranged in the extinguishing agent container 4 is a riser 6 , which leads into a valve 10 via an adapter 8 . The adapter piece 8 is seated in the region of the outlet opening 12 of the extinguishing agent container 4 and is preferably screwed tight there.

[0064] In the variant shown, the extinguishing agent container 4 is a steel cylinder whose inner surface has a lining 14 made of plastic in order to protect the material of the extinguishing agent container 4 against corrosion. Extinguishing fluid 16 , here in the form of water, is stored in the extinguishing agent container 4 in a compressed state. The extinguishing agent container 4 is preferably in standby mode with a static pressure of more than 5 bar, preferably more than 20 bar, especially more than 100 bar. By opening the valve 10 , the extinguishing fluid 16 is discharged from the extinguishing agent container 4 via t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com