Method for improving bias voltage stability of TFT (Thin Film Transistor) with oxide insulating layer prepared by solution method

A technology of oxide insulating layer and insulating layer, which is applied in the manufacture of transistors, electrical components, semiconductors/solid-state devices, etc., can solve the problems of the decline of electrical properties of thin films, the crystallization state of insulating layer films, etc., and achieve the reduction of internal defects and surface roughness degree, good bias stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

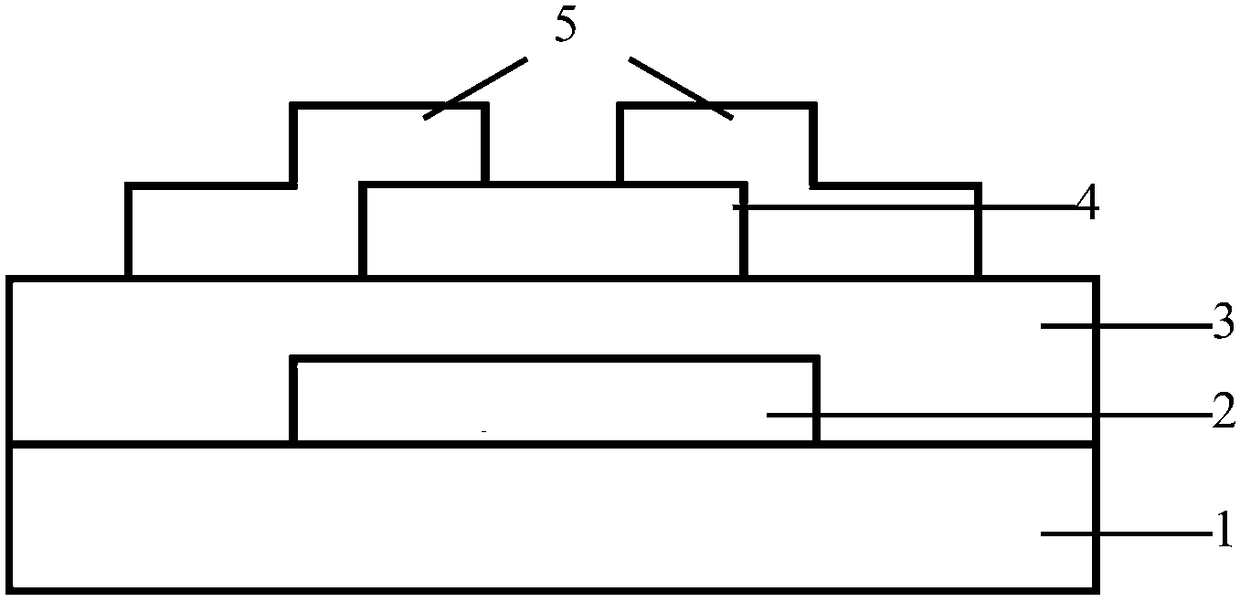

Method used

Image

Examples

Embodiment 1

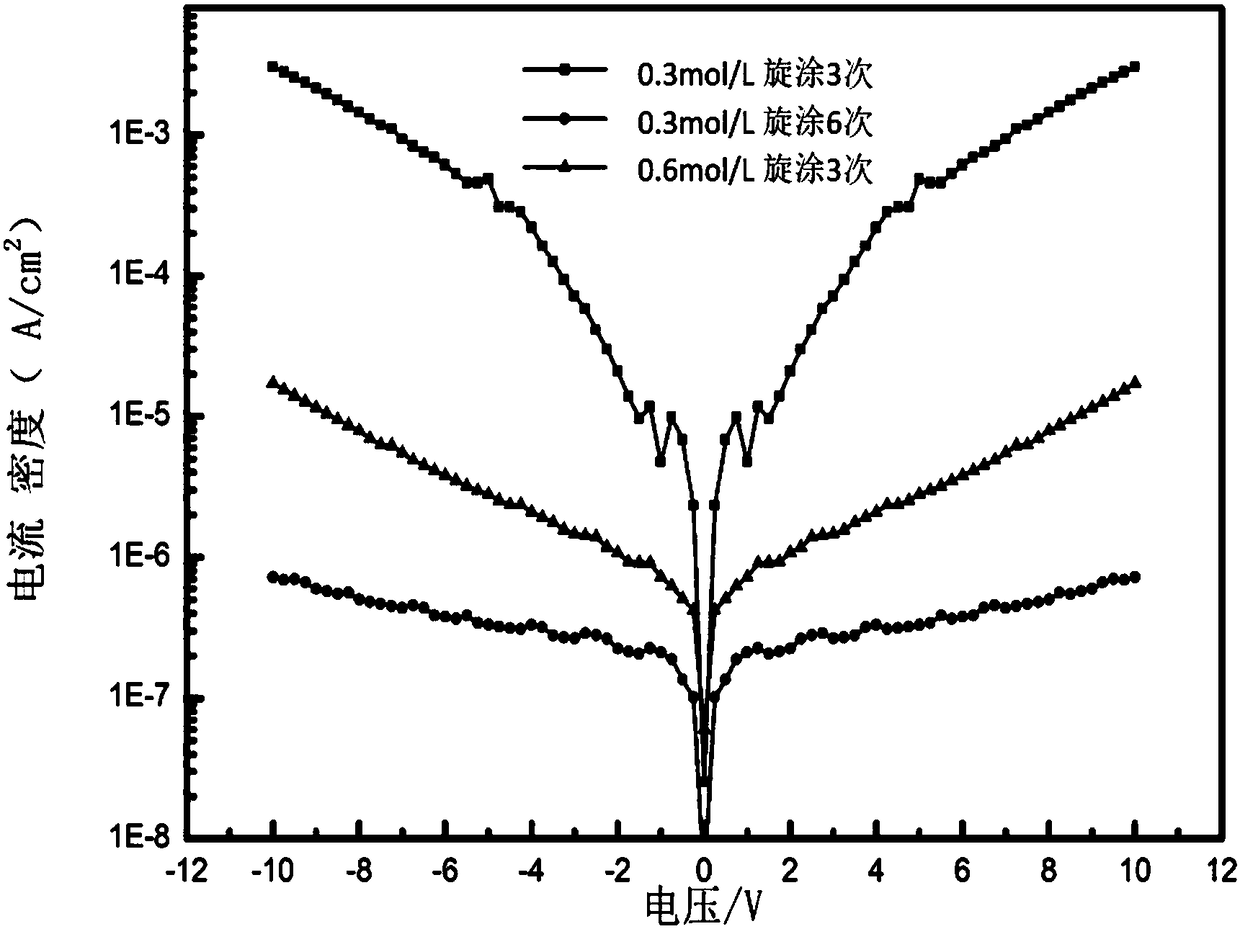

[0043] (1) Precursor preparation: 0.97g ZrOCl 2 ·8H 2 O (zirconium oxychloride octahydrate) was dissolved in 10ml ethylene glycol monomethyl ether (2-MOE), stirred and aged for 24h to obtain a 0.3mol / L precursor solution;

[0044] (2) Substrate preparation: deposit a layer of patterned ITO bottom gate (thickness is 150nm) on the surface of the glass substrate, wash and dry to obtain the ITO glass substrate;

[0045](3) On the ITO glass substrate (i.e. on the bottom grid), the precursor solution of step (1) is spin-coated multiple times (the spin-coating speed is 5000rpm, the number of times of spin-coating is 6 times, and the time of each spin-coating 40s (that is, the time for uniform glue)), annealing treatment (annealing at 300°C for 5min) after each spin coating, to obtain a metal oxide insulating layer film; then annealing the metal oxide insulating layer film at 350°C for 1h, to obtain Insulating layer; the metal oxide insulating layer film is a zirconia insulating lay...

Embodiment 2

[0048] Compared with Example 1, the concentration of the precursor solution is 0.26mol / L, the number of homogenization times is 7, the thickness of the insulating layer is 130nm, and other steps and conditions are completely the same.

Embodiment 3

[0050] Compared with Example 1, the concentration of the precursor solution is 0.2mol / L, the number of homogenization times is 9, and the thickness of the obtained zirconia insulating layer is 135nm. Other steps and conditions are completely the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com