Light prefabricated outer wall plate and preparing method thereof

A technology of prefabricated assembly and exterior wall panels, applied in the direction of building components, buildings, building structures, etc., can solve the problems of roof panel leakage, non-matching, self-heavy, etc., to improve the level of industrialization and standardization, improve construction efficiency, and ensure The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

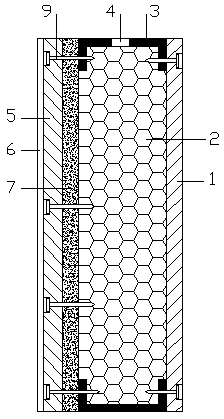

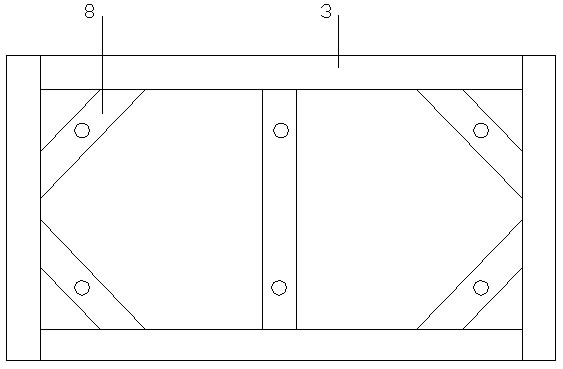

[0030] Such as figure 1 A light prefabricated exterior wall panel is shown, including a light steel keel frame 3, a rectangular frame surrounded by C-shaped steel, and diagonal ribs 8 arranged at the corners of the rectangular frame. Reinforcing ribs are also provided in the rectangular frame. Diagonal ribs can not only improve the strength of the skeleton, but also serve as the passing point of the connecting piece, so as to avoid the damage of the outer panel or the inner base plate caused by the connecting piece being too close to the edge.

[0031] The inner surface of the light steel keel frame 3 is fixedly connected with the inner base plate 1, and the outer surface of the light steel keel frame 3 is fixedly connected with the outer base plate 7, and a number of through holes are opened on the outer base plate 7, and the outer surface of the outer base plate 7 is fixed. An outer panel 5 is provided, and the outer surface of the outer panel 5 is provided with a plasterin...

Embodiment 2

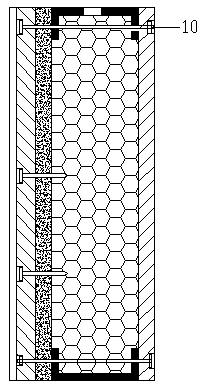

[0036] The difference between this embodiment and Embodiment 1 is that the profile of the light-duty keel frame is a thin-walled rectangular tube, and the threaded connection is a tension bolt 10 passing through the outer plate, the outer base plate, the light-duty steel keel frame and the inner base plate. On the light steel keel frame, there are reserved holes for the passage of the pull bolts, such as image 3 shown. The various parts are connected by the tension bolts, the reliability is higher, and the structural strength of the wallboard is further improved, and the hard foam polyurethane also plays the role of anti-loosening and rust prevention for the tension bolts.

[0037] The preparation method of above-mentioned two embodiment exterior wall boards, comprises the steps:

[0038] (1) Make the outer board, the outer base board and the inner base board, and open a number of through holes on the outer base board, wherein the outer board and the inner base board are aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com