Steel crown beam used for SMW construction method and assembly method thereof

An installation method and crown beam technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of chiseling construction troubles, increase the construction period, waste of three materials, etc., achieve convenient transportation and installation, and enhance bending rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

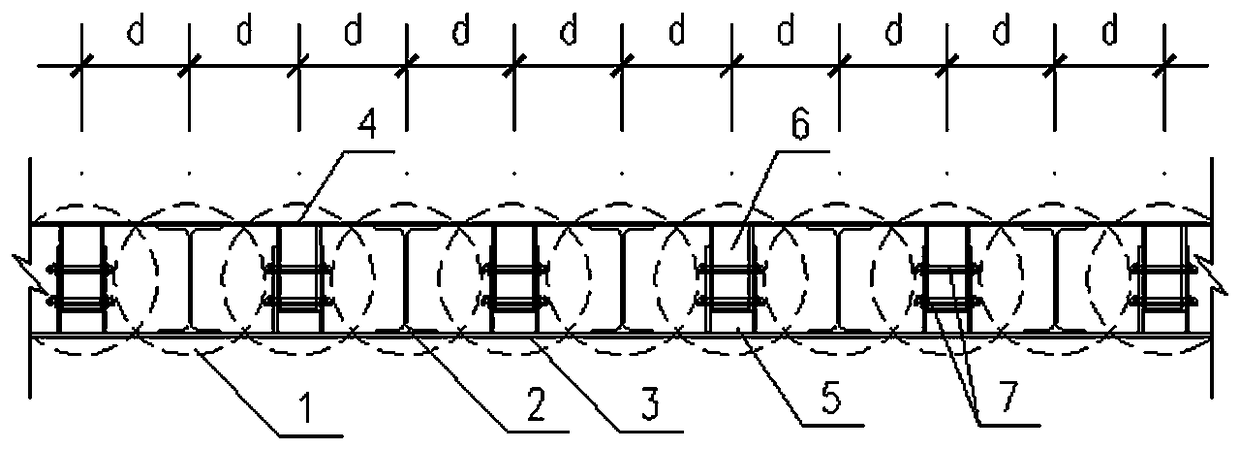

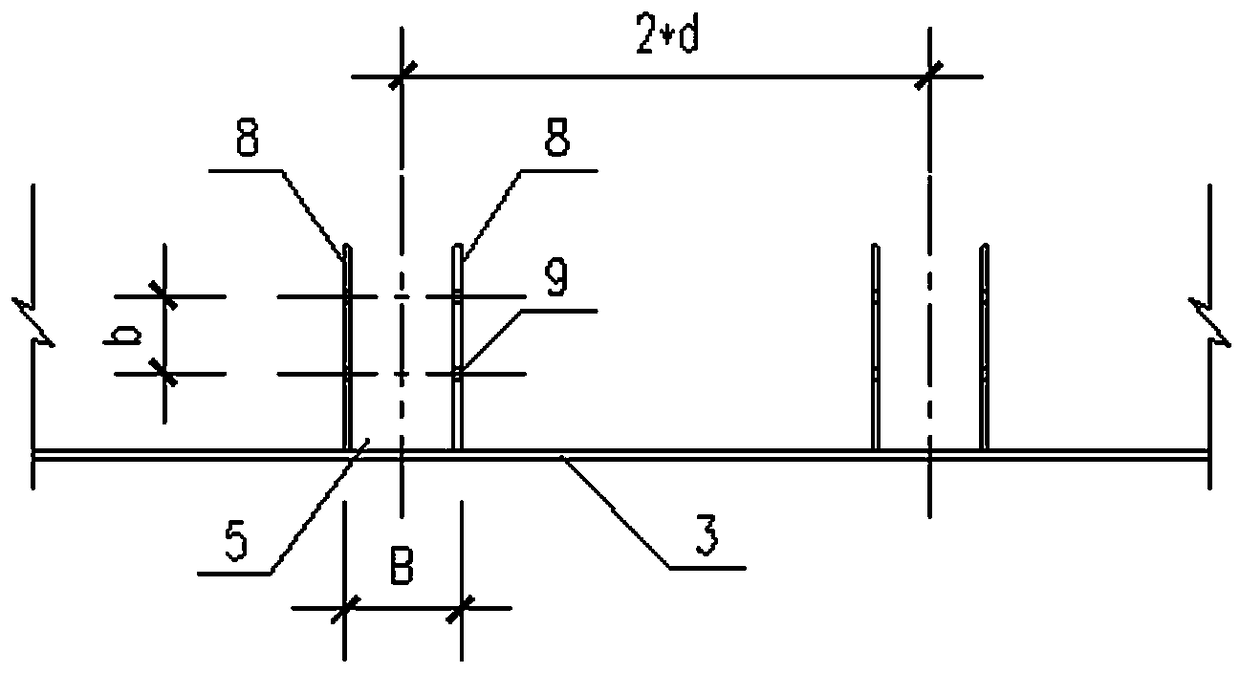

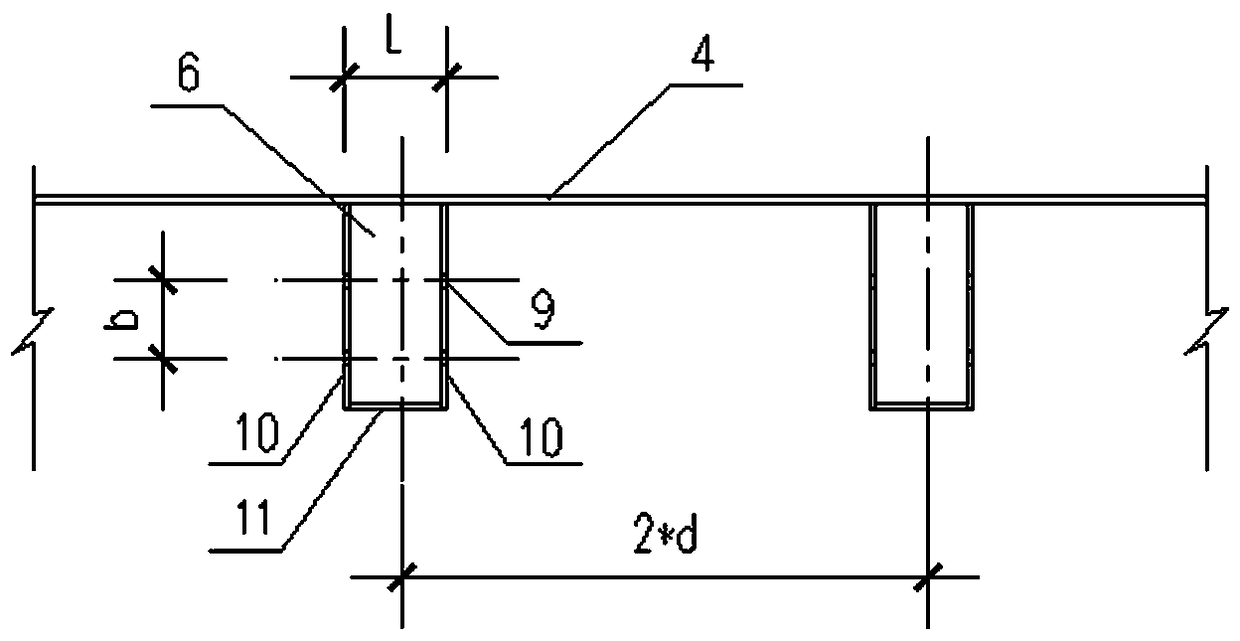

[0025] A foundation pit design in Shanghai adopts SMW construction method piles as the enclosure structure, biaxial mixing piles adopt φ700@500, section steel adopts HM500*300*11*18, crown beams are set on the top of construction method piles, and the inner and outer steel plates use 600mm*16mm, The side plate of the rib socket is made of 400mm*500mm*12mm steel plate, the socket width is 224mm, the side plate of the rib socket is made of 400mm*500mm*12mm steel plate, the end plate is made of 176mm*12mm steel plate, the socket width is 200mm, and the pull bolt is 4* M24. The spacing between the socket and the socket is 1000mm, the horizontal spacing of the pull bolts is 150mm, and the vertical spacing is 300mm. After the outer steel plate and the inner steel plate have welded the reinforcing ribs, they are connected by tension bolts to form a crown beam with a width of 520mm and a height of 600mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com