Large-scale concrete mixing engine for irrigation works

A technology for mixing host and concrete, applied in cement mixing devices, clay preparation devices, unloading devices, etc., can solve the problem of low mixing volume per tank, reduce production management, ensure mixing quality, and reduce the number of mixing buildings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

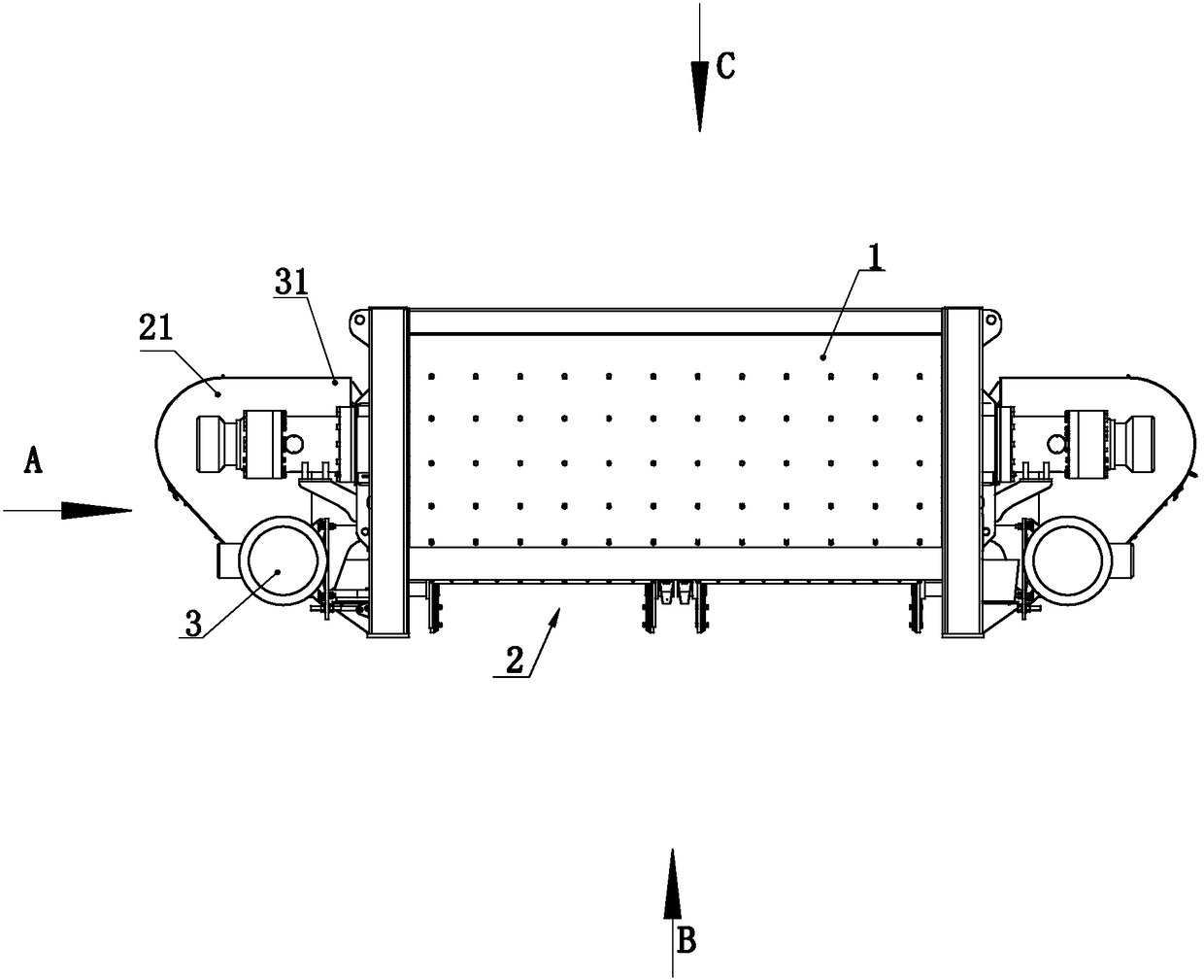

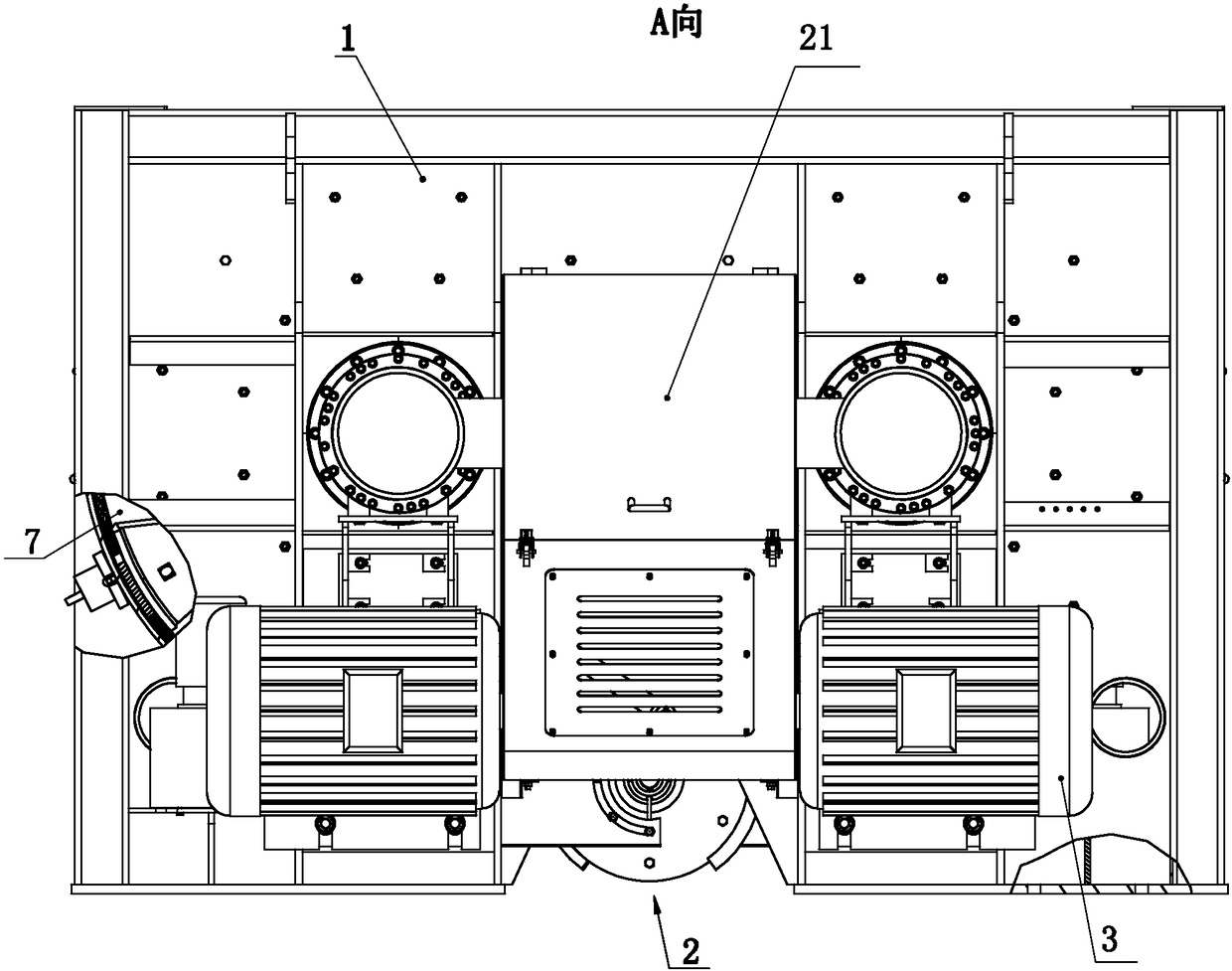

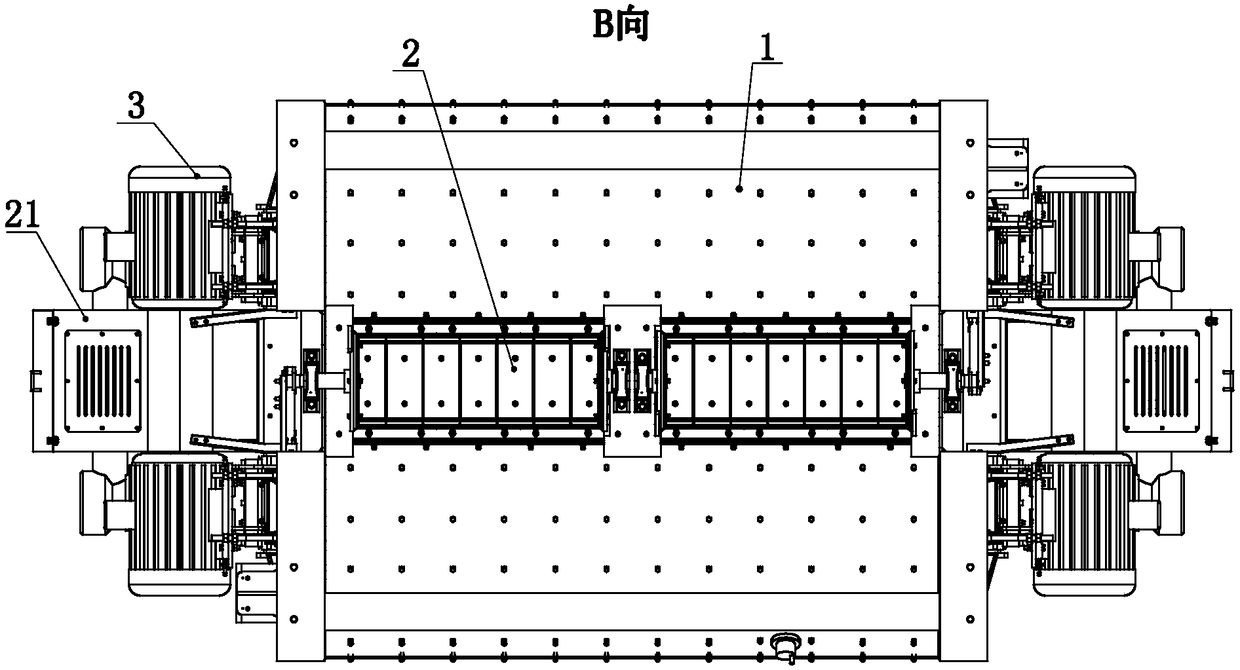

[0030] like Figure 1 to Figure 4 As shown, the present invention includes a stirring tank 1, a stirring device and a drive system. The bottom of the stirring tank 1 is provided with two discharge doors 2, and each discharge door 2 is connected to the stirring tank 1 in rotation, and each discharge door 2 Each transmission is connected with a hydraulic drive package for driving the discharge door 2 to rotate. The hydraulic drive package is provided with a cabinet 21 at both ends of the outside of the mixing tank 1, and the hydraulic drive package is arranged in the cabinet 21. The size of each discharge door 2 is the same, and the axis of rotation of each discharge door 2 on the mixing tank 1 is coaxially arranged. The stirring tank 1 is about 7 meters long, about 3.2 meters wide, and about 2.2 meters high. The stirring tank 1 is respectively provided with lining plates 11 for flow guiding at the positions of the discharge openings where the discharge doors 2 are located. Th...

Embodiment approach 2

[0039] like Figure 4 to Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the structure of the stirring blade 6 is different, and the end of the stirring blade 6 near the rotating shaft 4 is defined as the inner end of the stirring blade 6, and the end of the stirring blade 6 away from the rotating shaft 4 is defined as The outer end of stirring blade 6.

[0040] The structure of the stirring blade in the present embodiment is as Figure 7 As shown, the long and wide surfaces of the stirring blade 6 are rectangular, and the outer end of the stirring blade is provided with a chute 61, and the length direction of the chute 61 extends along the side of the long and wide surface of the agitating blade at the outer end. In this embodiment, by setting the chute 6, the axial flow of the mixed material is strengthened, which is conducive to improving the mixing efficiency and mixing effect, that is, along the direction parallel to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com