Centrifugal rotary crystallizer and recovery tower for efficiently recovering carbon dioxide

A carbon dioxide, centrifugal rotation technology, applied in crystallization separation, solution crystallization, chemical instruments and methods, etc., can solve the problems of high mother liquor circulation rate, excessive equipment, large investment and other problems, achieve small equipment size, energy saving, crystallization Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

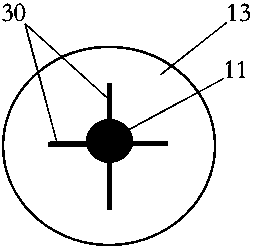

[0022] like Figure 1 to Figure 3 A centrifugal rotating crystallizer for efficiently recovering carbon dioxide is shown, including: a crystallization body 10, a motor 20 that drives the crystallization body to rotate, and heat sinks 30 installed on both sides of the crystallization body 11. The crystallization body 10 includes a central axis 11, several crystallization tubes 12. The fixed structure 13 and the reinforcement structure 14, one end of the central axis 11 is connected to the motor 20, a plurality of crystallization tubes 12 surround the central axis 11 and are arranged in parallel with the central axis 11, and the two ends of the crystallization tubes 12 are respectively fixed to a The structure 13 is fixed, the fixed structure 13 is sleeved on the central shaft 11 and the position is fixed, the reinforcing structure 14 reinforces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com