A flat-tube solid oxide battery structure and its preparation method for improving yield and single-cell power

A solid oxide and single-cell technology, applied in the shape/form of fuel cells, fuel cells, electrochemical generators, etc., can solve the problems of lower battery yield, difficult release of stress, and unavoidable stress inside the battery, etc. , to achieve the effect of increasing the power generation area and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

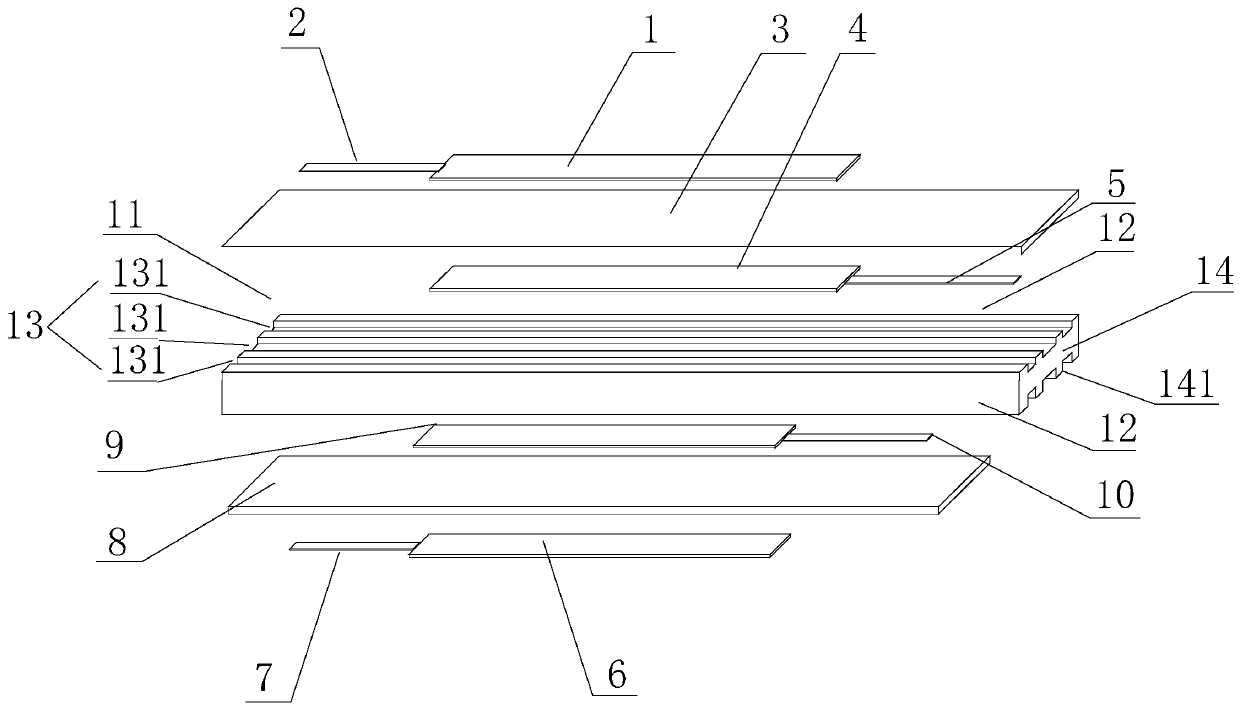

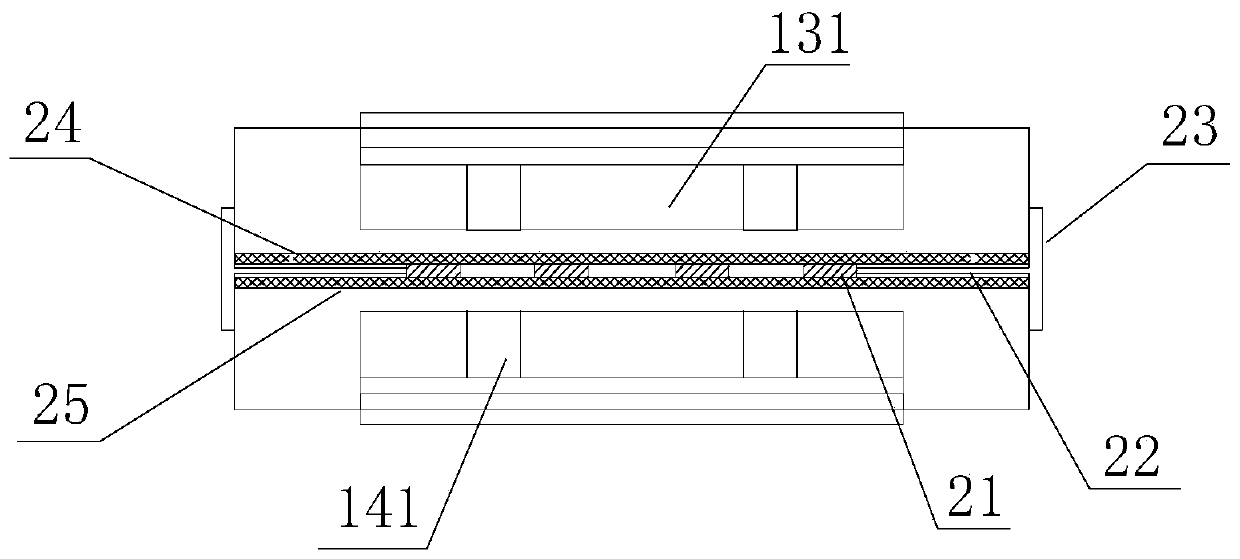

[0072] Such as figure 1 Shown: a flat tube solid oxide battery structure with improved yield and single cell power, including a first outer electrode 1, a first outer electrode connecting wire 2, a first electrolyte 3, a first inner electrode 4, a first inner The electrode connecting wire 5, the second outer electrode 6, the second outer electrode connecting wire 7, the second electrolyte 8, the second inner electrode 9, the second inner electrode connecting wire 10 and the isolation structure 11. Wherein, the first and second external electrodes and the first and second internal electrodes are in a planar form; and the first external electrode and the first internal electrode are respectively an oxygen-rich electrode and an oxygen-depleted electrode; the second external electrode and the second The internal electrodes are respectively an oxygen-rich electrode and an oxygen-deficient electrode.

[0073] The first outer electrode and the first outer electrode connecting wire are ...

Embodiment 2

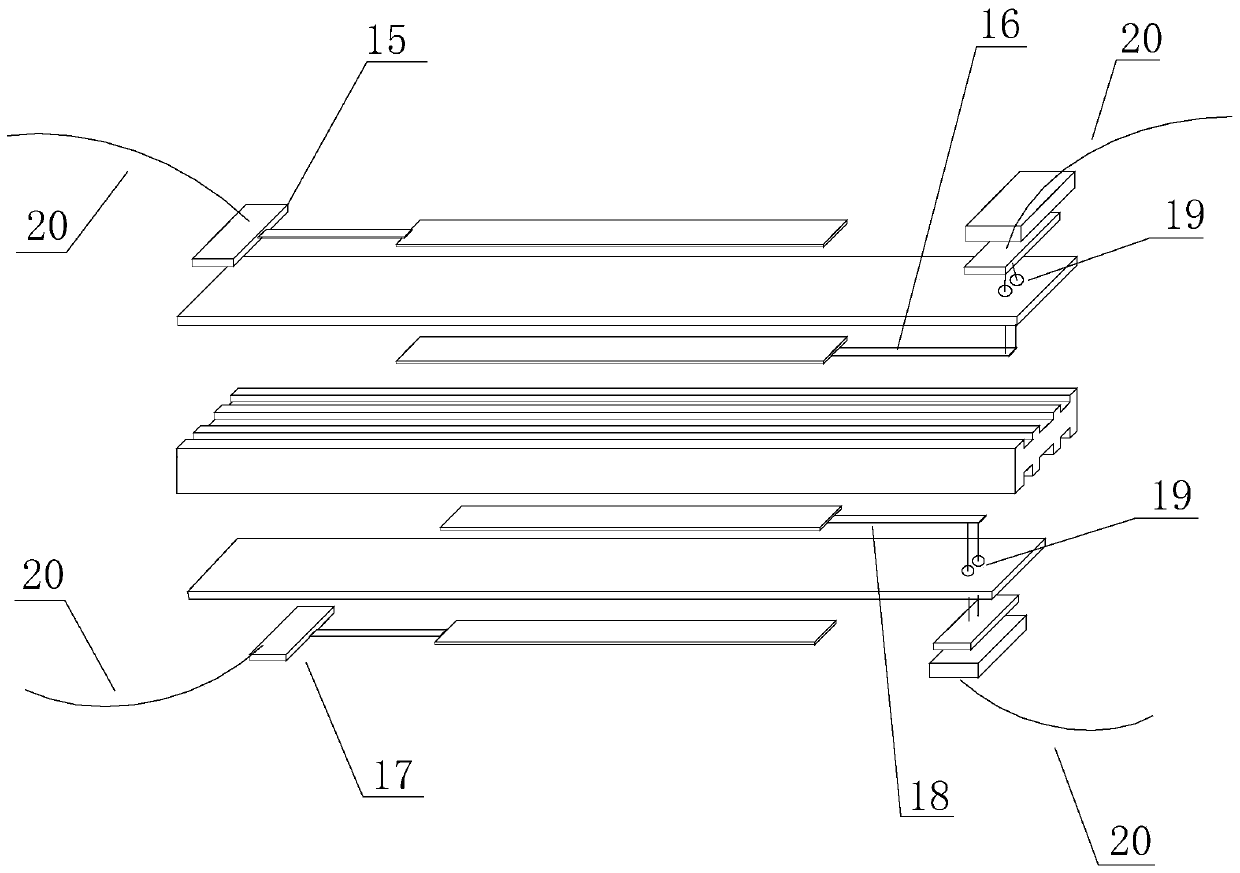

[0081] Such as figure 2 Shown: a flat tube solid oxide battery structure with improved yield and single cell power, including a first outer electrode 1, a first outer electrode connecting wire 2, a first electrolyte 3, a first inner electrode 4, a first inner Electrode connecting wire 5, second outer electrode 6, second outer electrode connecting wire 7, second electrolyte 8, second inner electrode 9, second inner electrode connecting wire 10, first outer electrode pin 15, first inner electrode The pin 16, the second outer electrode pin 17, the second inner electrode pin 18 and the isolation structure 11. Wherein, the first and second external electrodes and the first and second internal electrodes are in a planar form; and the first external electrode and the first internal electrode are respectively an oxygen-poor electrode and an oxygen-rich electrode; and the second external electrode and the first The two internal electrodes are respectively an oxygen-poor electrode and a...

Embodiment 3

[0089] Such as figure 2 As shown, a flat tube solid oxide battery structure with improved yield and single cell power includes a first external electrode 1, a first external electrode connecting wire 2, a first electrolyte 3, a first internal electrode 4, and a first internal Electrode connecting wire 5, second outer electrode 6, second outer electrode connecting wire 7, second electrolyte 8, second inner electrode 9, second inner electrode connecting wire 10, first outer electrode pin 15, first inner electrode The pin 16, the second outer electrode pin 17, the second inner electrode pin 18 and the isolation structure 11. Wherein, the first and second external electrodes and the first and second internal electrodes are in a planar form; and the first external electrode and the first internal electrode are respectively an oxygen-poor electrode and an oxygen-rich electrode; and the second external electrode and the first The two internal electrodes are respectively an oxygen-poo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com