Accurate deformation control-oriented multilayer and multi-pass welding technology for hollow stabilizer bars of automobiles

A multi-layer multi-pass welding and deformation control technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high cost, time-consuming, laborious, interference, etc., to improve quality, optimize process design, reduce The effect of experimental workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

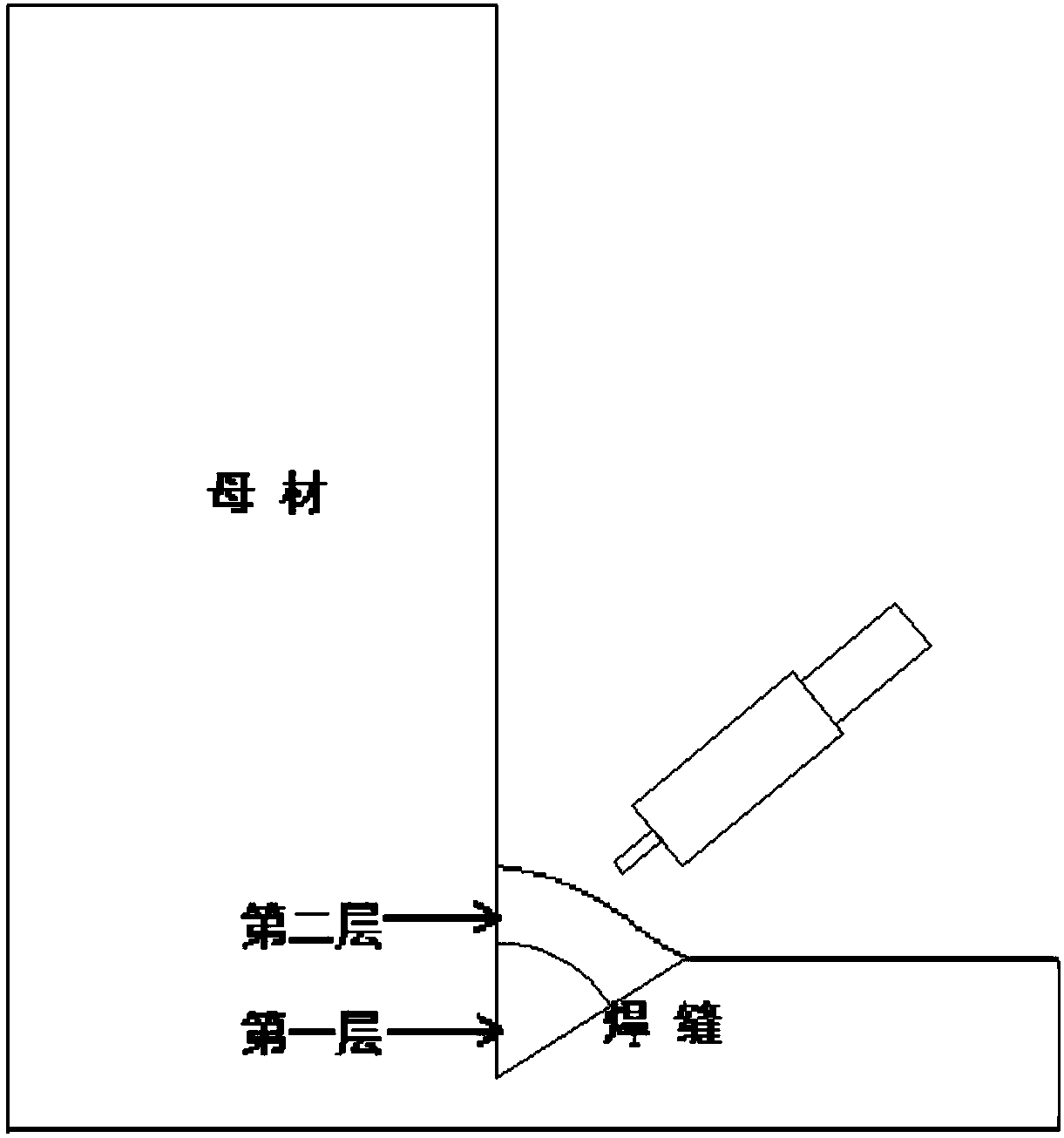

[0032] refer to figure 1 As shown, a kind of automobile hollow stabilizer bar multi-layer multi-pass welding process for precise deformation control of the present invention comprises steps as follows:

[0033] According to the geometric shape of the automobile hollow stabilizer bar, a 3D geometric model that matches the actual situation is established; specifically, when modeling in 3D modeling software, it is necessary to comprehensively consider the groove design of multi-layer multi-pass welding and the number of layers of welds divided.

[0034] Carry out grid division for the 3D geometric model established above; specifically, the grid division is related to the accuracy and efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com