Protection device for several flying objects in blasting

A protective device and flying object technology, applied in blasting and other directions, can solve problems such as low construction efficiency, laborious handling, and heavy workload, and achieve the effects of preventing dust from escaping, ensuring safety, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

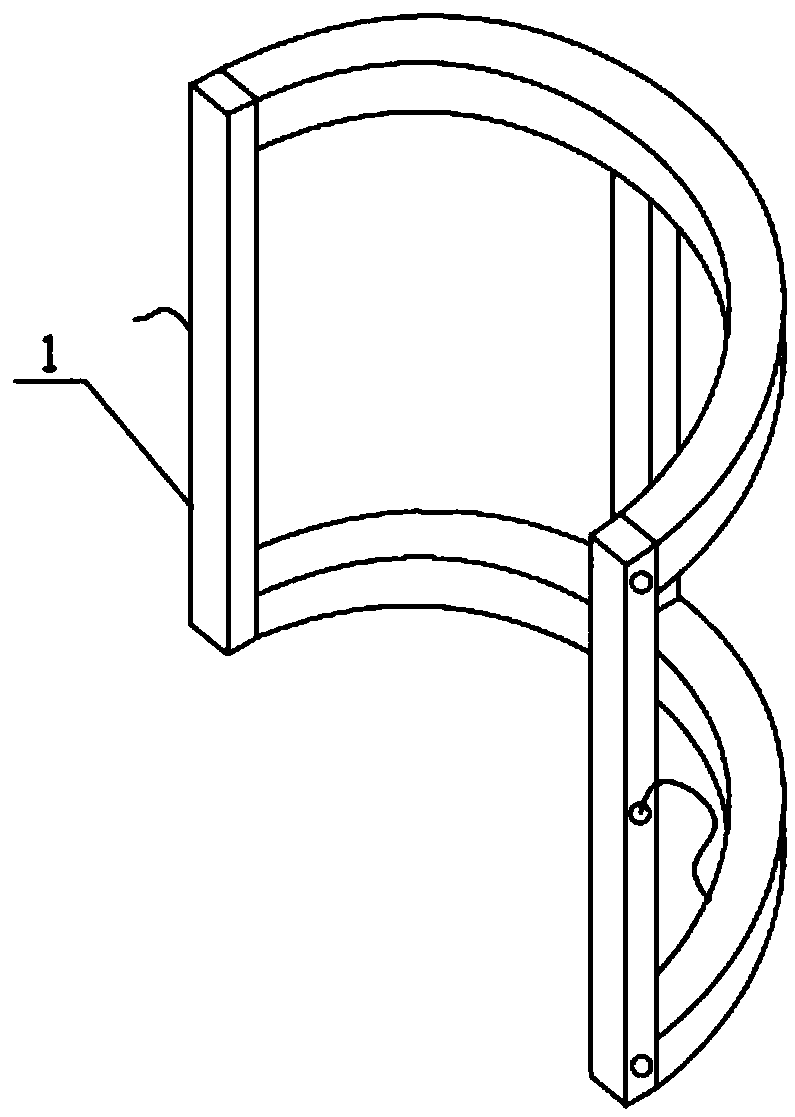

[0025] Such as figure 1 As shown, the present embodiment provides a protection device for blasting individual flying objects, which is installed on a rectangular parallelepiped column and includes a first frame 1 , a second frame 2 , a first protective net 3 and a second protective net 4 .

[0026] Four first frames 1 are arranged on the four sides of the column, and the first protective net 3 is wound on the outside of the first frame 1 in one or more layers, so that the first protective net 3 is close to the column. The second protective net 4 is arranged in the second frame 2, the number of the second frame 2 is the same as that of the first frame 1, the second frame 2 is attached to the first frame 1, and the second frame 2 is connected to the first frame by a fastener. The frame 1 is fixedly connected, and the fastener passes through the mesh of the first protective net 3 . Adjacent second frames 2 are connected by connecting pieces 5 , and there is a gap between the fir...

Embodiment 2

[0035] This embodiment provides a blasting individual flying object protection device, which is installed on a rectangular parallelepiped column. Its structure is substantially the same as that of Embodiment 1, from the inside to the outside are the first frame 1, the first protective net 3, the water bag 6 and the second frame 2 with the second protective net 4 installed. The difference is that due to the different shapes of the columns, the shapes of the first frame 1 attached to it and the second frame 2 attached to the first frame 1 also change accordingly.

[0036] Such as figure 2 As shown, both the first frame 1 and the second frame 2 are composed of two parallel semicircular rods and a support rod connecting the two semicircular rods, and both the first frame 1 and the second frame 2 are two. Adjacent first frames 1 are connected through connecting pieces 5 , and adjacent second frames 2 are connected through connecting pieces 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com