Automotive electronic water pump

A technology for electronic water pumps and vehicles, applied to pumps, components of pumping devices for elastic fluids, pump devices, etc., can solve problems such as poor heat dissipation performance, welding failure of welding points, lack of fixed structures, etc. The effect of stability, lower operating temperature, and simple fixed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

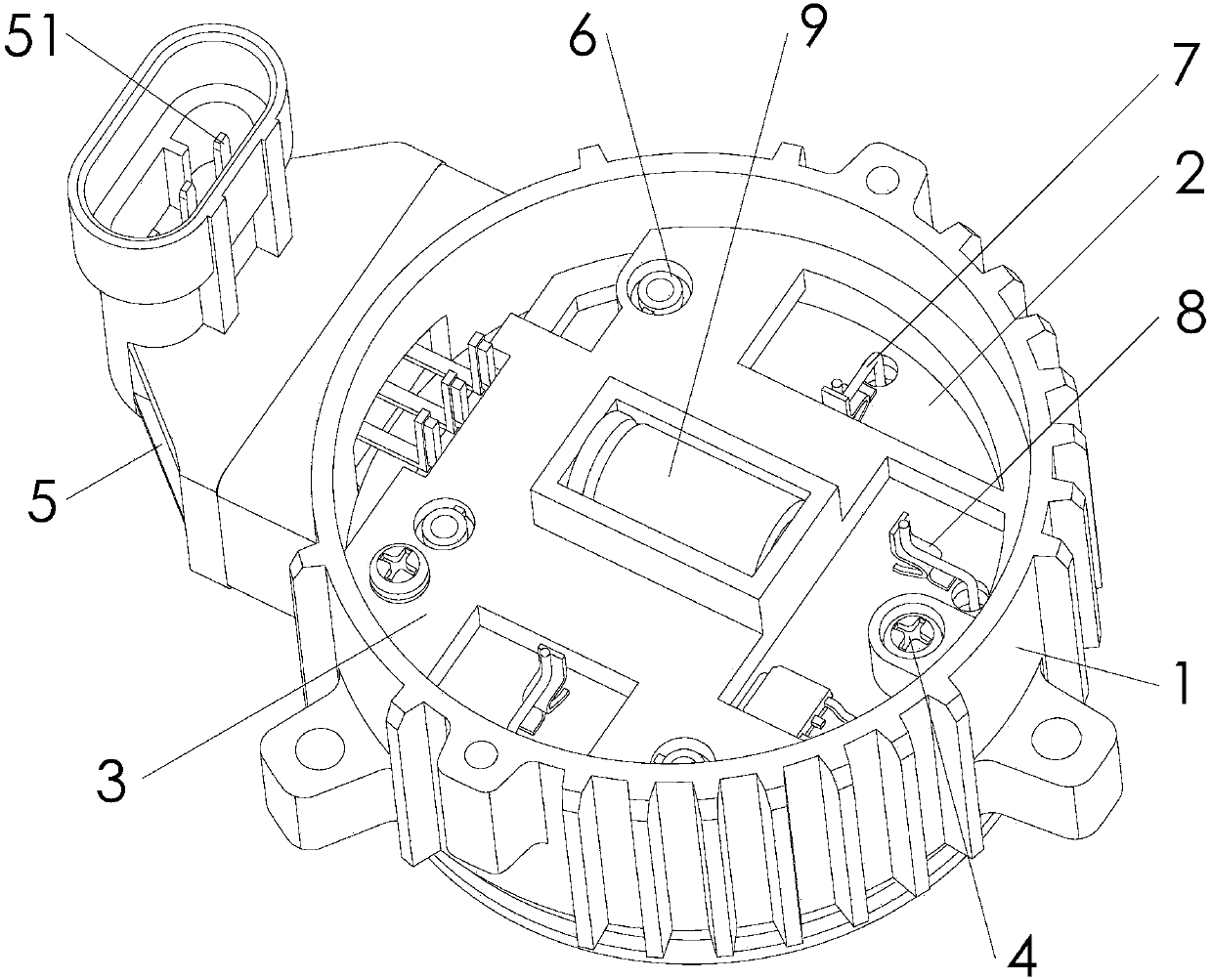

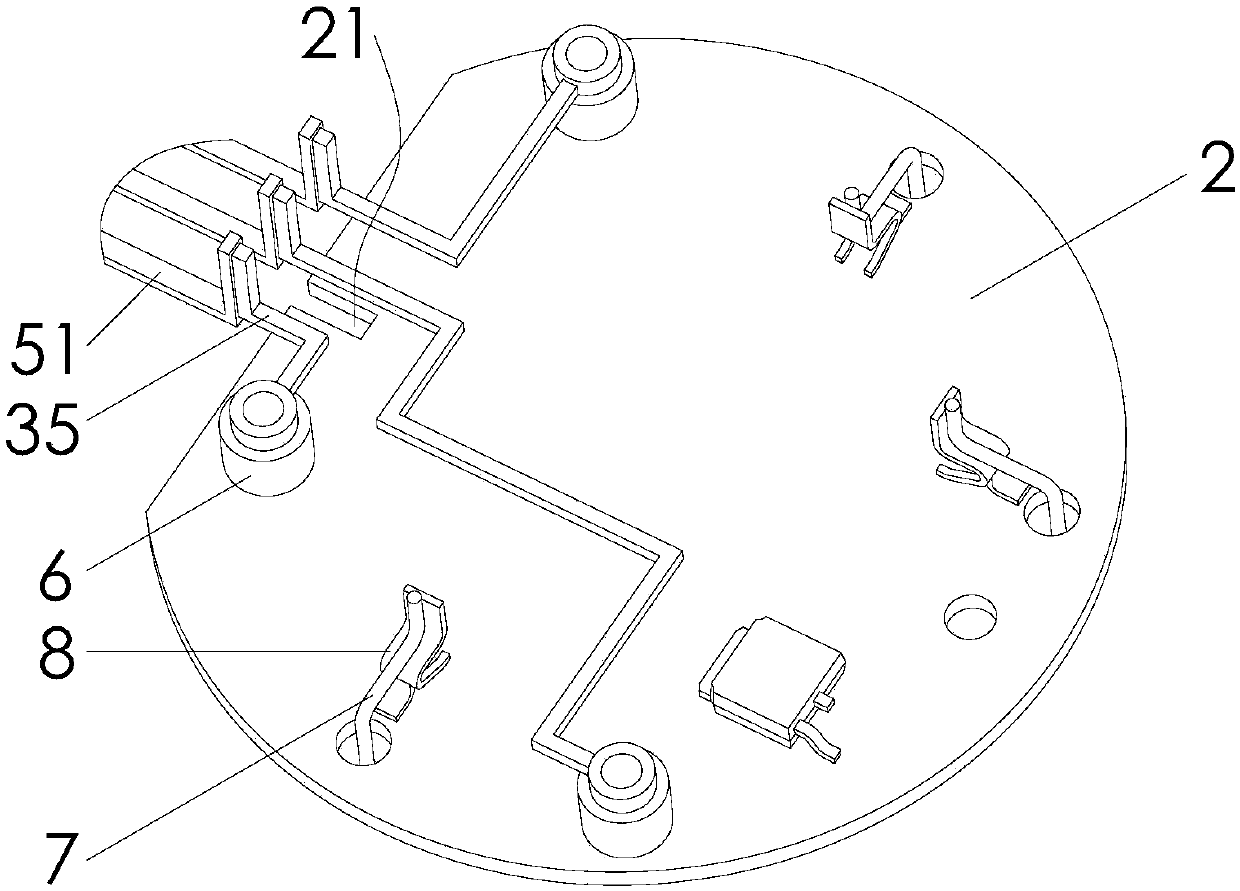

[0037] Such as figure 1 , figure 2 As shown, the electronic water pump for vehicles provided by Embodiment 1 of the present invention includes a pump casing 1, a motor, an impeller and a control board 2 are arranged in the pump casing, the motor includes an output shaft, a rotor assembly and a stator assembly, and the impeller is fixed on the output shaft superior. The vehicle electronic water pump in this embodiment also includes a fixing assembly, and the control board 2 is arranged in the pump housing 1 through the fixing assembly.

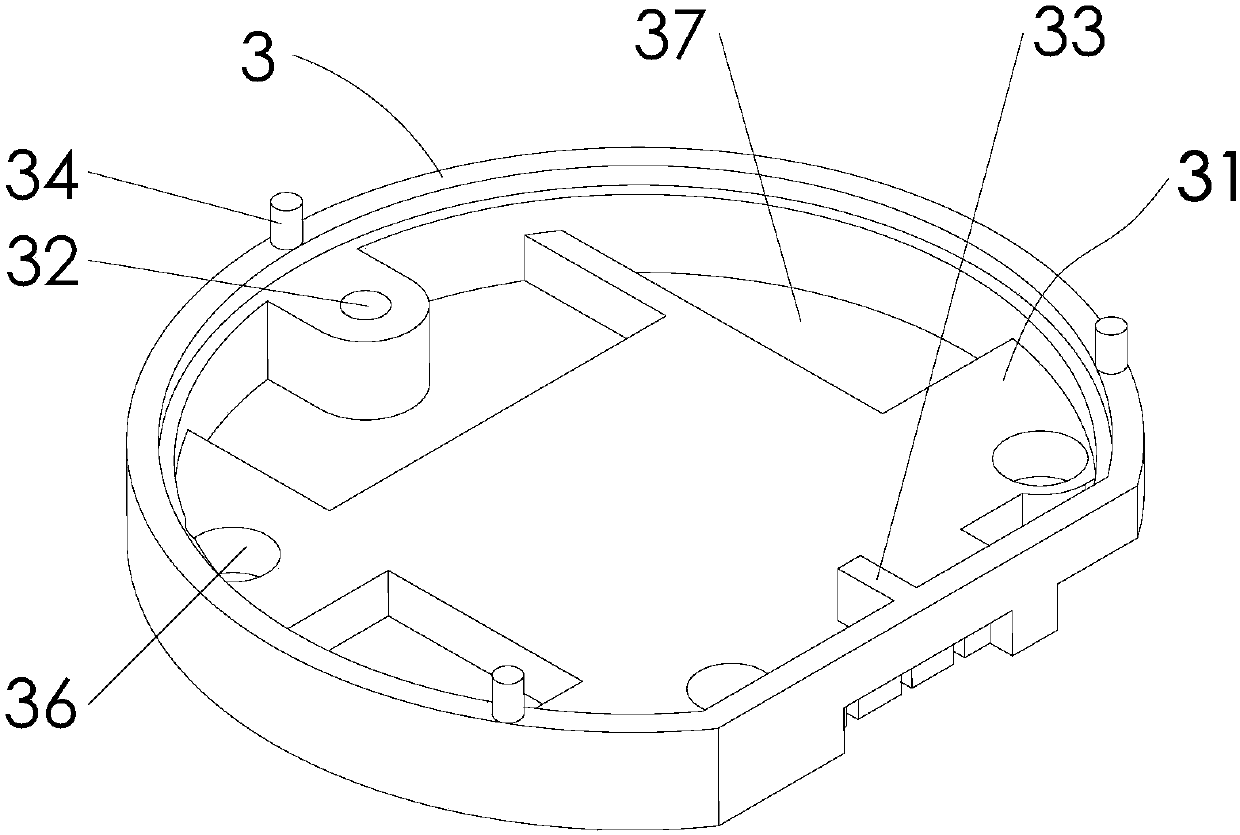

[0038] Such as image 3 , Figure 4 As shown, the fixing assembly includes a bracket 3, and one side of the bracket is provided with a concave cavity 31 for accommodating the control board 2. When the bracket is fixed in the pump casing 1, the control board 2 is located in the space formed by the concave cavity 31 and the inner wall of the pump casing 1. Inside.

[0039] The fixing assembly also includes screws 4. The bracket 3 is provided ...

Embodiment 2

[0056] The difference between Embodiment 2 of the present invention and Embodiment 1 above is that the bracket 3 is fixed in the pump housing 1 by means of gluing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com