Method for steel sheet pile cofferdam construction in deepwater thick-sludge-layer environment

A technology of steel sheet pile cofferdam and construction method, which can be used in infrastructure engineering, construction and other directions, and can solve problems such as low efficiency

Inactive Publication Date: 2018-07-27

SICHUAN ROAD & BRIDGE GRP

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

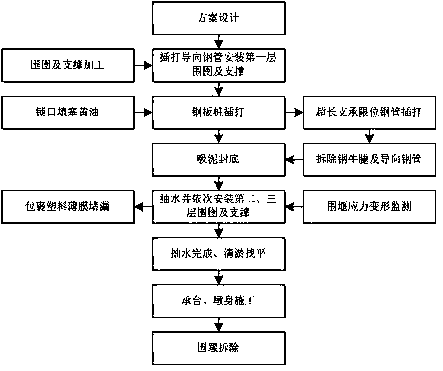

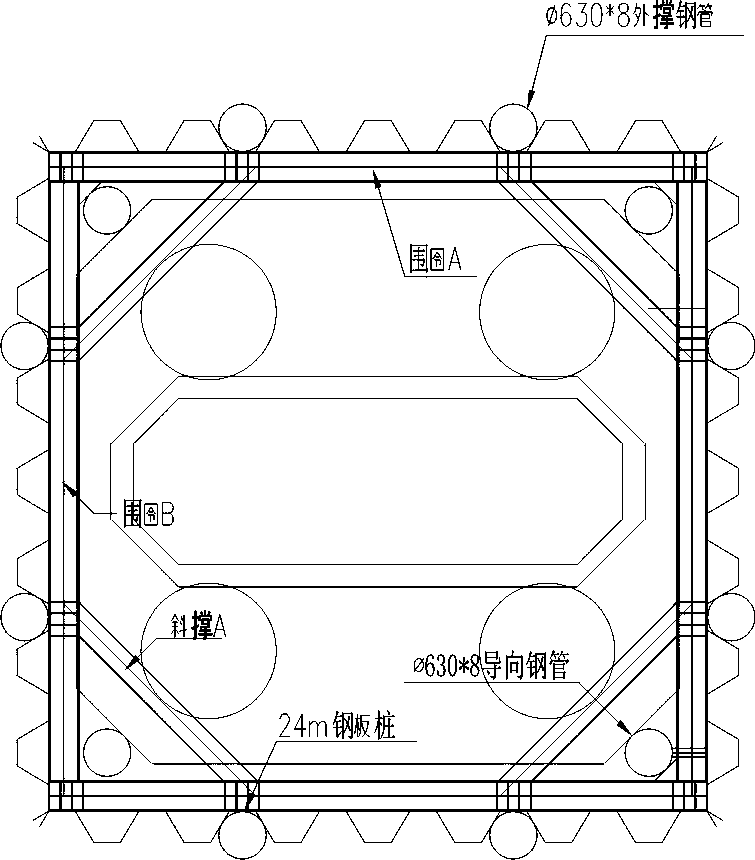

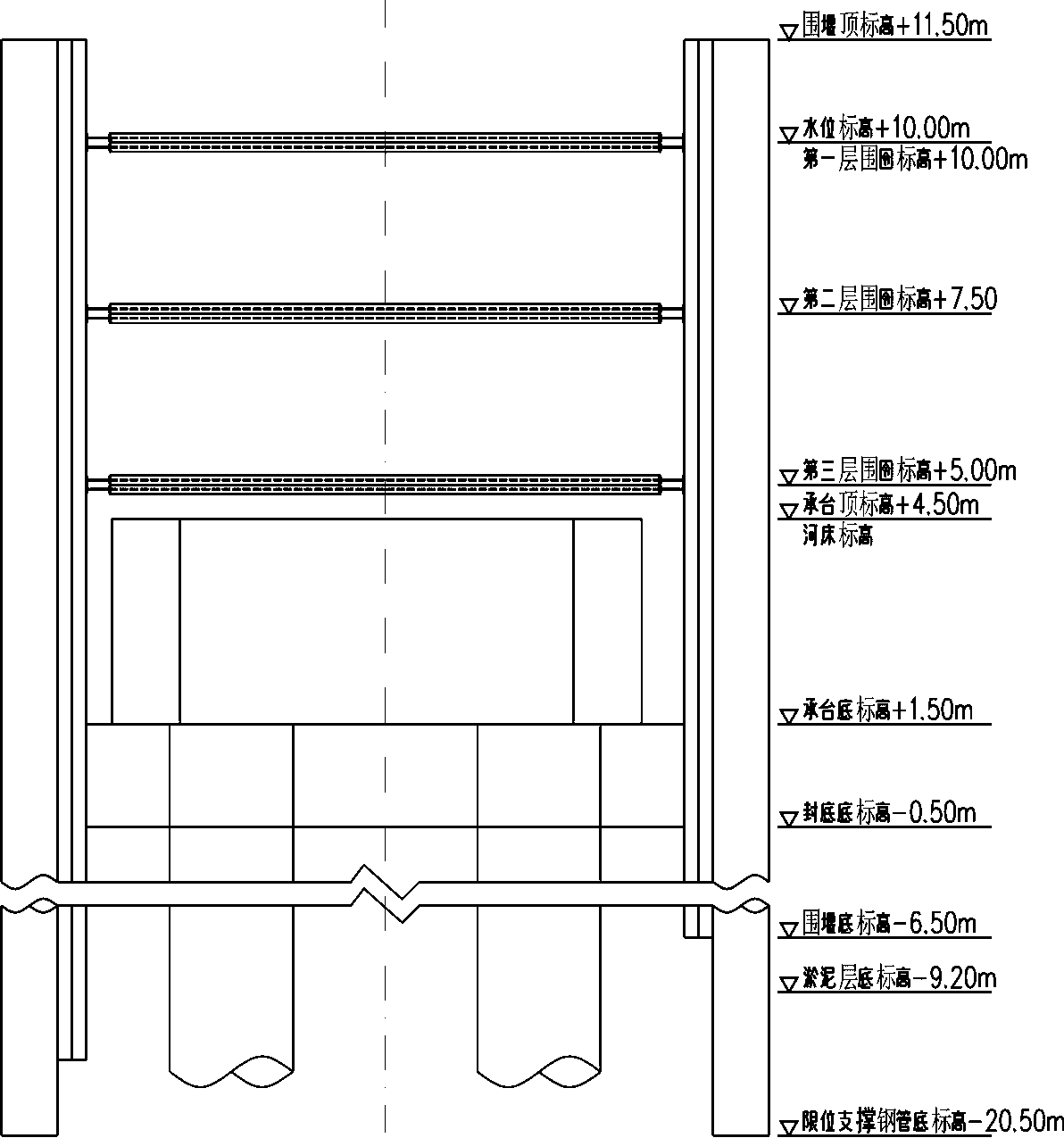

[0003] Therefore, in order to solve the above-mentioned deficiencies, the present invention provides a steel sheet pile cofferdam construction method, which solves the technical problem of deep-water foundation construction under the geological conditions of thick silt layer; Pile, the first layer of internal support is placed on the guide steel pipe pile and serves as the steel sheet pile guide frame. Long steel sheet piles are used to improve the embedding stability of the cofferdam in silt geology; after the steel sheet pile cofferdam is closed, steel pipe piles are inserted around the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for steel sheet pile cofferdam construction in a deepwater thick-sludge-layer environment. In construction, four guide steel pipe piles are inserted into the inner side of a supporting ring beam, first inner supports are placed on the guide steel pipe piles to serve as steel plate pile guide frames, the long and short steel sheet piles are inserted alternately andwelded to the first layer of inner supporting ring beam one by one, and building-in stability of a cofferdam in sludge can be improved by the aid of inner supporting auxiliary steel pipe piles and long steel sheet piles. After closure of the steel sheet pile cofferdam, steel pipe piles are inserted around the outer side of the cofferdam to realize supporting assistance. By a combined sludge suction pump and a telescopic boom grab bucket, sludge suction and dredging to bottom-sealing bottom elevation and pouring of underwater bottom sealing concrete can be realized, and the problem of low efficiency of a traditional air compressor reverse circulation sludge suction process under thick-sludge-layer geological conditions is solved. Plastic thin film strips are hung and filled in an outer sealing gap of the steel sheet pile cofferdam from top to bottom, the thin films are plugged into the sealing gap along with water flow under pressure difference resulted from pumping in the cofferdam, and accordingly water stop effects are achieved.

Description

technical field [0001] The invention relates to a cofferdam construction method, in particular to a steel sheet pile cofferdam construction method in deep water and thick mud layer environment. Background technique [0002] Nowadays, there are more and more bridges over water. In order to ensure the safety of navigation, more and more wading bridge foundations are buried under the river bed. For the geological conditions where the riverbed cover is dominated by deep and thick silt layers, the construction of super-long steel sheet piles is difficult due to the impact of the embedding depth of the cofferdam. Steel hanging boxes and locked steel pipe piles are often used as cofferdams in this special environment. The stability of the cofferdam is problematic, but the construction cost of the cofferdam of the steel hanging box and the locking steel pipe pile is high and the process is complicated. The present invention provides a steel sheet pile cofferdam construction method ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D19/04

CPCE02D19/04

Inventor 牟行勇明德江郭跃孙兵汪捍东何良飞李东山

Owner SICHUAN ROAD & BRIDGE GRP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com