NiO/Ni catalyst and preparation method and application thereof

A catalyst and application technology, applied in the field of electrocatalysis, can solve problems such as limited utilization, and achieve the effects of simple operation, high stability and strong anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

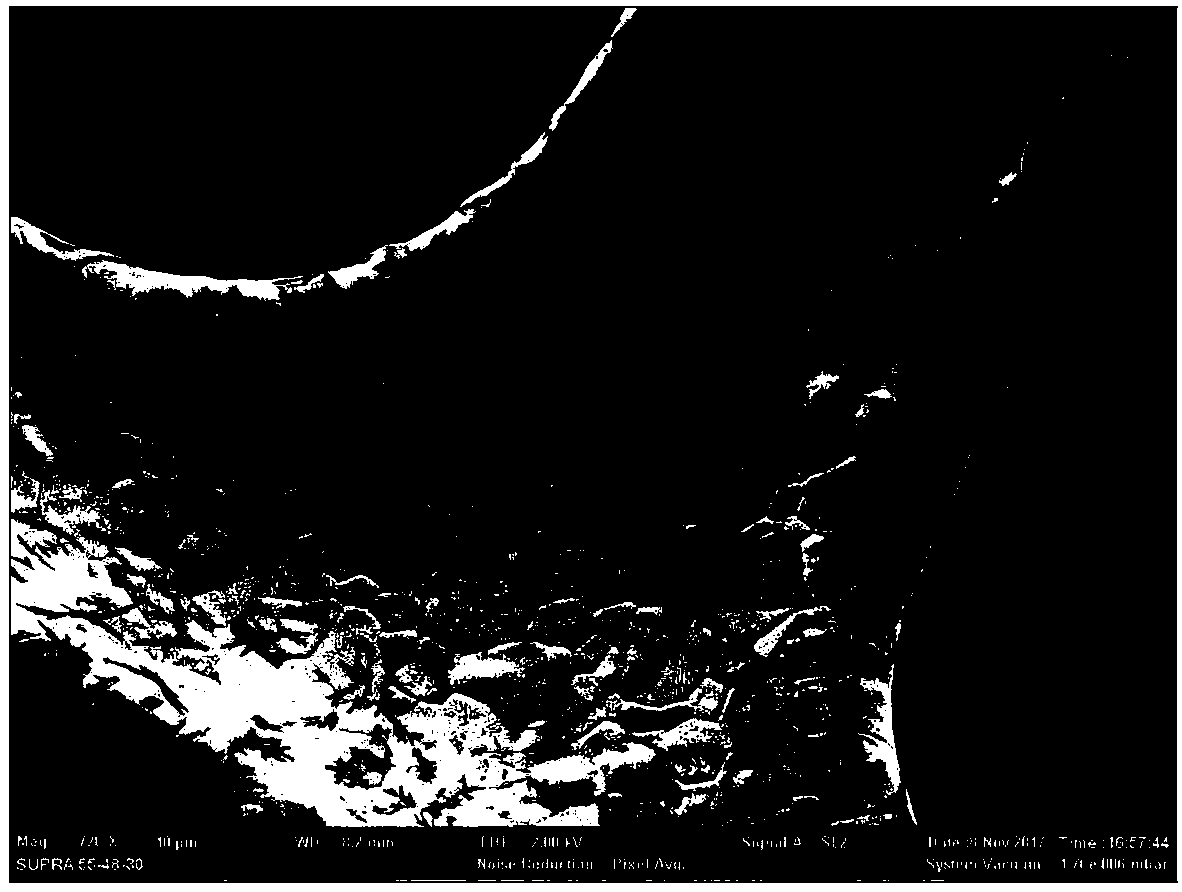

Image

Examples

Embodiment 1

[0023] Using a three-electrode system, mercury-mercury oxide is used as a reference electrode, platinum wire is used as a counter electrode, and NiO / Ni obtained through linear scanning and linear cyclic voltammetry is used as a working electrode, and the scanning speed is 1mV / s, and the number of scanning cycles is 500 , the range is 0 to 0.7v, the methane of 10mL / Min flow rate is passed into the 0.1mol / L NaOH solution, uses the potentiostatic method to carry out electrolysis reaction, and the applied voltage is 0.2V, and the output of ethanol is 60.3μmol / (g· h), the whole process is simple to operate, high in stability and stable in product quantity.

Embodiment 2

[0025] Using a three-electrode system, mercury-mercury oxide is used as a reference electrode, platinum wire is used as a counter electrode, and NiO / Ni obtained through linear scanning and linear cyclic voltammetry is used as a working electrode, where the scanning speed is 100mV / s and the number of scanning cycles is 500 , the range is 0 to 0.7v, the methane of 10mL / Min flow rate is passed into the 0.1mol / L NaOH solution, uses the potentiostatic method to carry out electrolysis reaction, and the applied voltage is 0.2V, and the output of ethanol is 25.8μmol / (g· h), the whole process is simple to operate, high in stability and stable in product quantity.

Embodiment 3

[0027] Using a three-electrode system, mercury-mercury oxide is used as a reference electrode, platinum wire is used as a counter electrode, and NiO / Ni obtained through linear scanning and linear cyclic voltammetry is used as a working electrode, and the scanning speed is 1mV / s, and the number of scanning cycles is 500 , the range is 0 to 0.7v, the methane of 10mL / Min flow rate is passed into the 0.1mol / L NaOH solution, uses the potentiostatic method to carry out electrolysis reaction, and the applied voltage is 1.0V, and the output of ethanol is 37.5μmol / (g· h), the whole process is simple to operate, high in stability and stable in product quantity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com