Regulation device for heat-recovery coke oven gas collecting system

An adjustment device and heat recovery technology, which is applied in the direction of dry distillation gas discharge device, coke oven, coke oven heating, etc., can solve the problems of heavy weight, low resistance to rapid cooling and rapid heating, etc., to reduce labor intensity and increase long-term High temperature resistance performance, the effect of ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

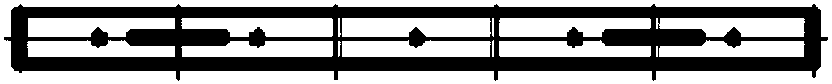

[0013] Such as Figure 1-3 As shown, a heat recovery coke oven gas collection system adjustment device in this embodiment includes a polycrystalline temperature-resistant and pressure-resistant stainless steel frame 2, a rib plate 3, heat-insulating cotton 4 and two cover plates 5, a plurality of The ribs 3 are perpendicular to each other and equidistantly arranged in the polycrystalline temperature-resistant and pressure-resistant stainless steel frame 2 to form a grid, and the heat-insulating cotton 4 is filled in the grid formed by the ribs 3. The upper edge of the pressure stainless steel frame body 2 is evenly opened with several differential pressure discharge holes 1, and two cover plates 5 are respectively covered on the upper surface and the lower surface of the polycrystalline temperature-resistant and pressure-resistant stainless steel frame body 2. The top of the crystal temperature-resistant and pressure-resistant stainless steel frame body 2 is also provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com