Wing spar die

A technology of wing beams and molds, which is applied in the field of mechanical devices and transportation, can solve problems such as self-weight deformation and large positioning errors, and achieve the effects of improving process precision and quality, improving work efficiency, and ensuring positioning accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

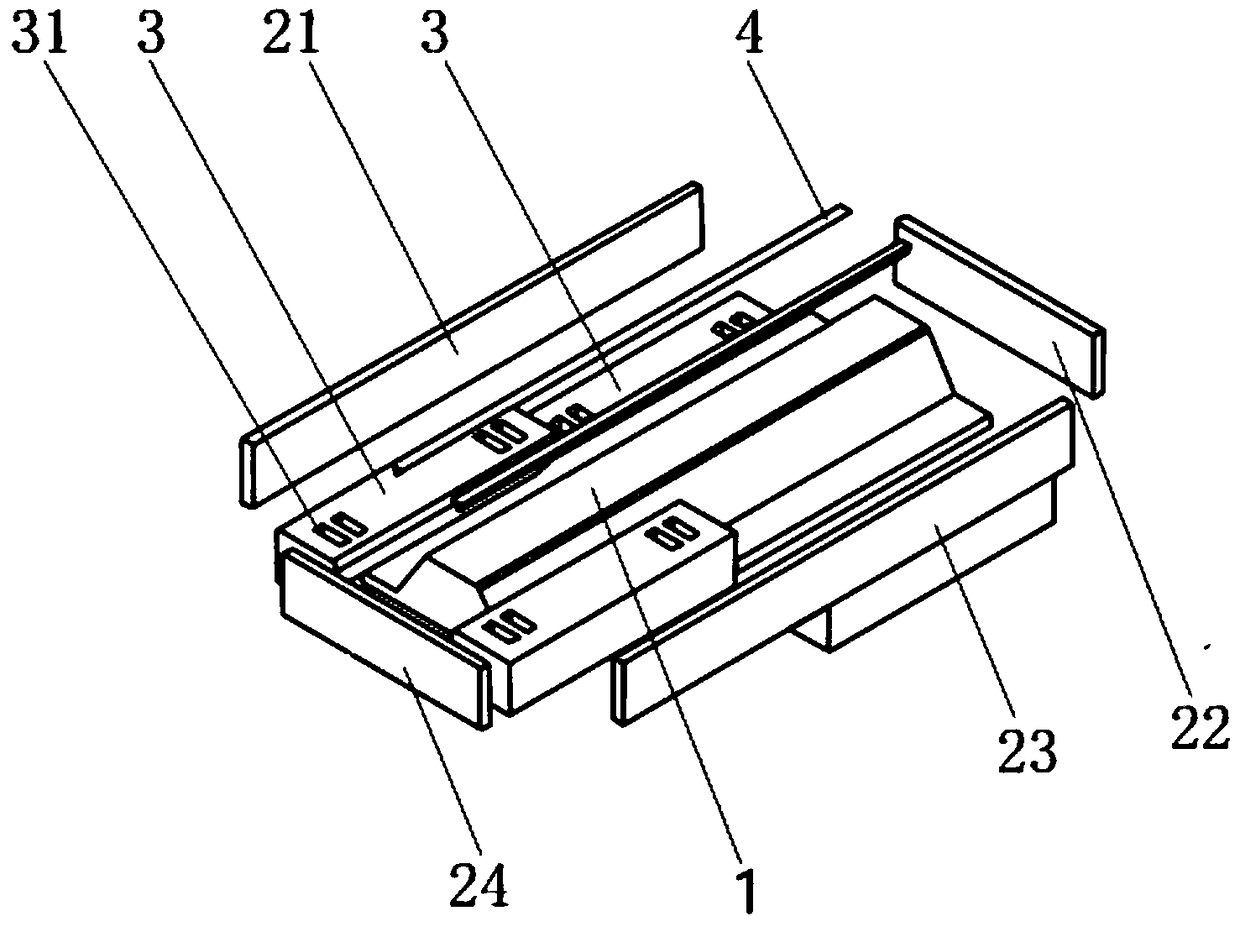

[0036] figure 2 It is an exploded perspective view of the spar mold provided by the present invention.

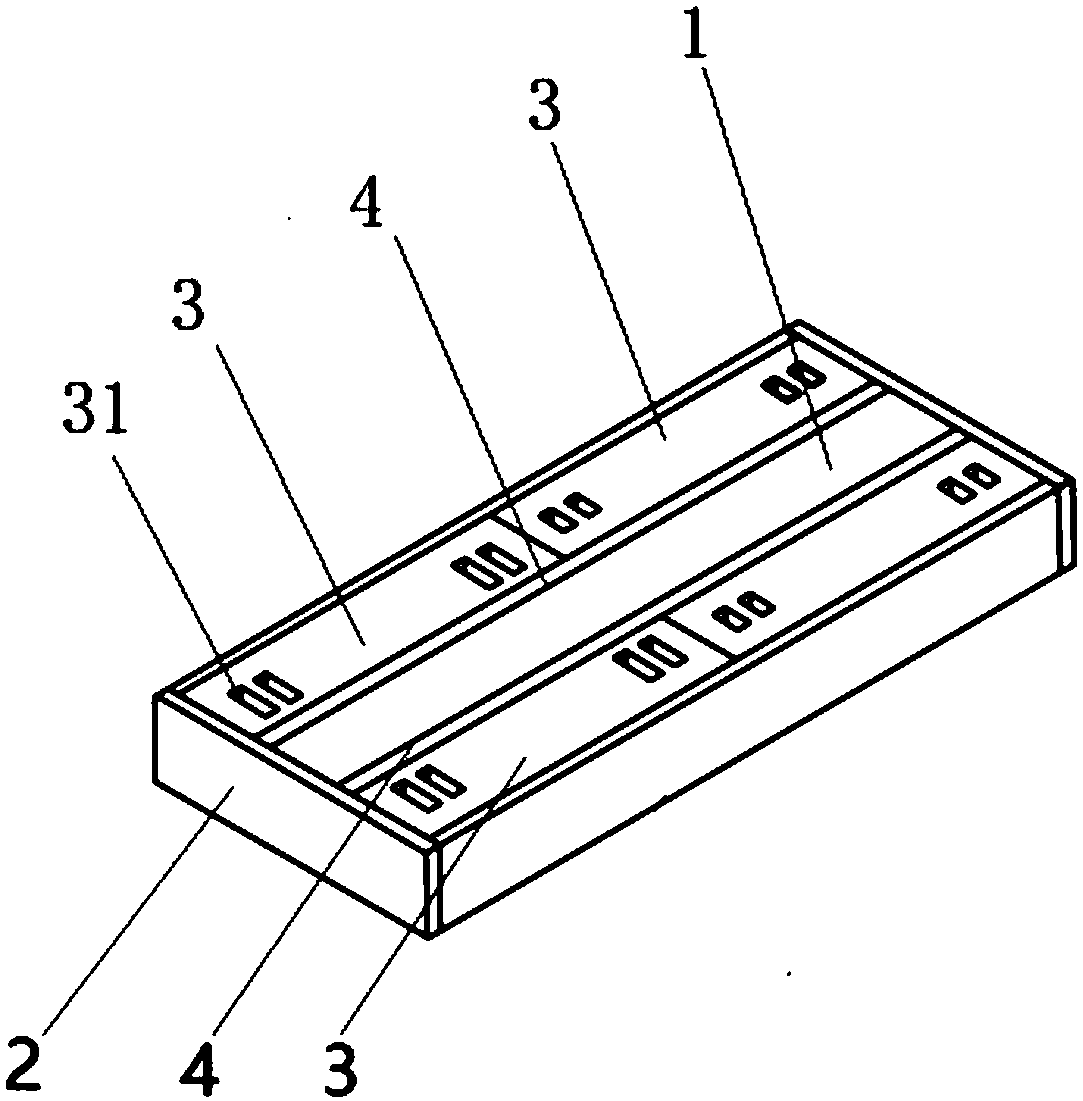

[0037] image 3 It is an assembly perspective view of the spar mold provided by the present invention.

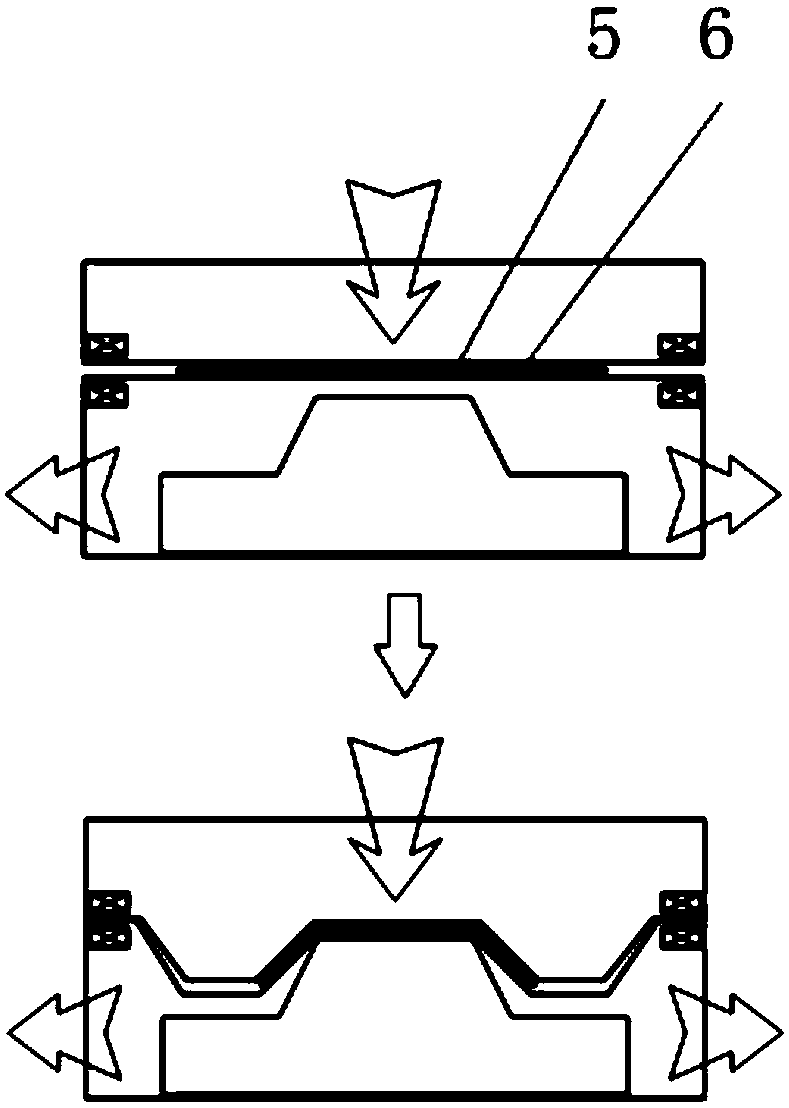

[0038] Such as figure 2 , image 3 As shown, this embodiment provides a spar mold for the thermal diaphragm forming process of a composite spar, including: a forming boss 1 , a frame body 2 and a filling block 3 .

[0039] The forming boss 1 is used for forming the thermal diaphragm of the spar in the thermal diaphragm equipment to make it into the desired shape.

[0040] Optionally, the cross-sectional shape of the forming boss 1 is trapezoidal, C-shaped or arc-shaped.

[0041] The frame body 2 is detachably arranged around the forming boss 1, and is used to form a mold frame with shaping and force bearing functions.

[0042] Optionally, the cross section of the frame body 2 is rectangular, but the present invention is not limited thereto, and the cross section ...

Embodiment 2

[0068] Figure 5 It is a three-dimensional schematic diagram of the structure of the filling bar provided by the present invention.

[0069] Such as figure 2 , image 3 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that, according to the actual situation, when there is a gap between the forming boss 1 and the filling block 3 due to the difference in shape, the spar mold also includes: filling strips 4.

[0070] The filling strip 4 is arranged in the gap formed between the forming boss 1 and the filling block 3 for filling the gap.

[0071] Optionally, the upper surface of the filling strip 4 is on the same plane as the upper surface of the forming boss 1 .

[0072] Optionally, the upper surface and the bottom surface of the filling bar 4 , the filling block 3 and the frame body 2 are all on the same height plane as the forming boss 1 .

[0073] Optionally, the filling strip 4 is integrally formed or arranged in sections, and its total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com