Device and method for carrying away wood chips which emerge laterally from a continuous press

A technology of press and sawdust, applied in the field of installation of sawdust or other wood particles, can solve problems such as consumption, and achieve the effect of simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

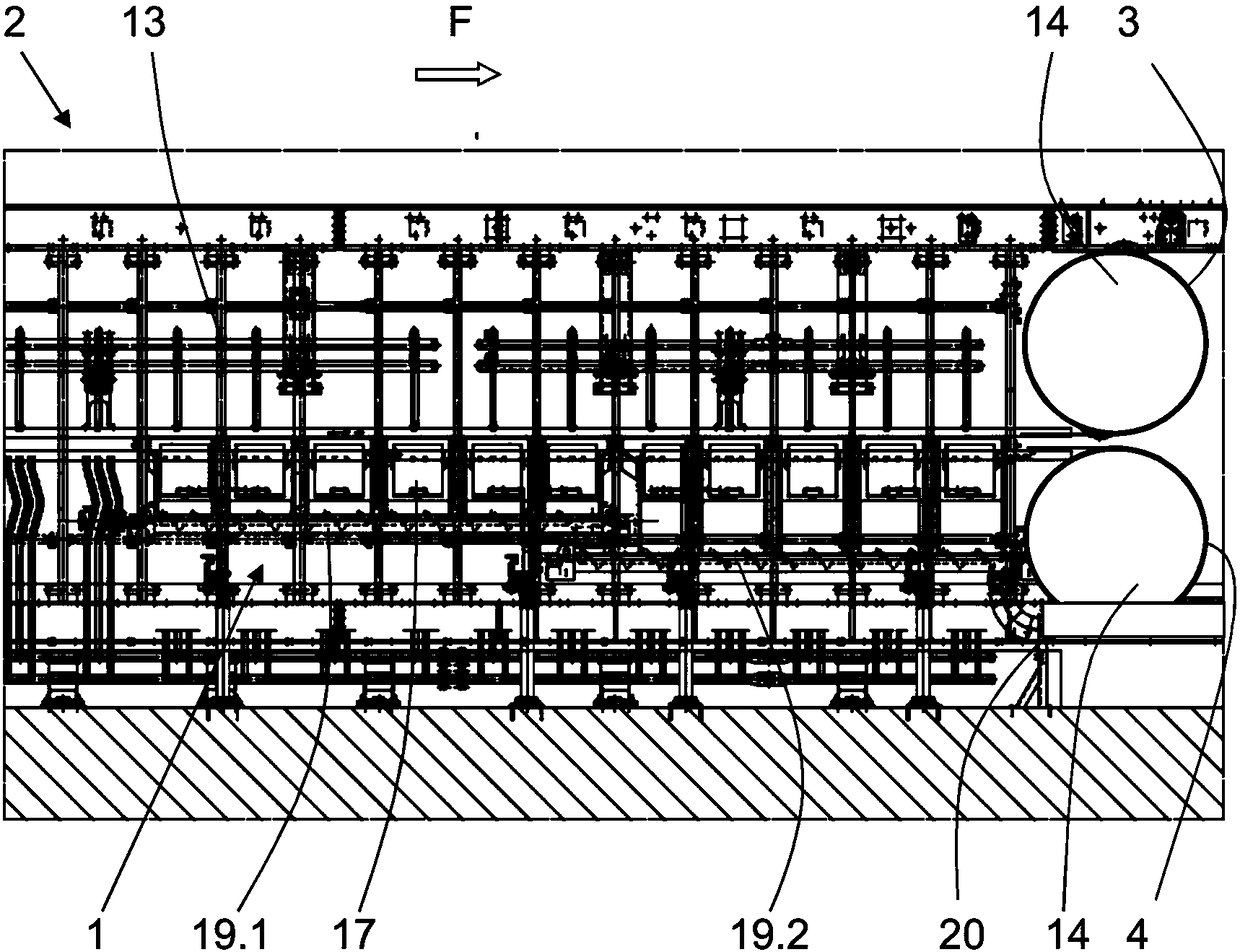

[0030] figure 1 and 2 The same installation with a continuous double-belt press 2 and the device 1 according to the invention is shown from two different viewing directions (as a cross section and as a side view).

[0031] exist figure 2 One end of a continuous double-belt press 2 with a surrounding upper belt 3 and a surrounding lower belt 4 is seen in the figure. The upper belt 3 and the lower belt 4 form a pressing gap 5 in which at least a majority of the wood material 6 consisting of wood chips or other wood particles is pressed.

[0032] The pressing process takes place via an upper pressing plate 7 and a lower pressing plate 8 , at least one of which is directed towards at least one surrounding belt 3 via a hydraulic pressing cylinder 9 , for example with roller bodies not shown interposed therebetween. , 4 squeeze and thus close the squeeze gap 5 and act on the wood 6 . The squeeze cylinders 9 are fixed, for example, on the respective frame 13 and are supplied wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com