Mechanical idesia crushing equipment

A kind of crushing equipment and mechanical technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of manpower consumption and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

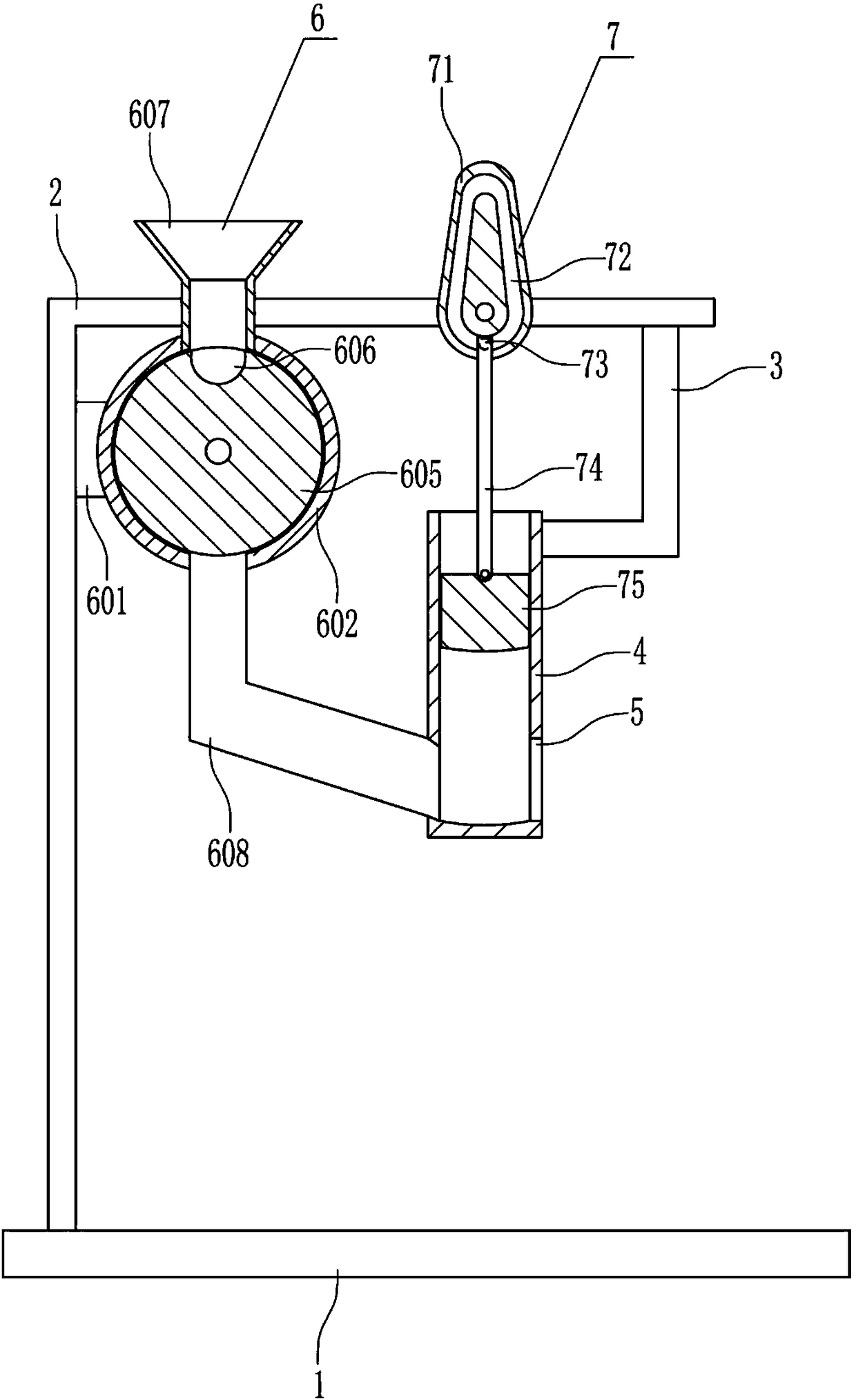

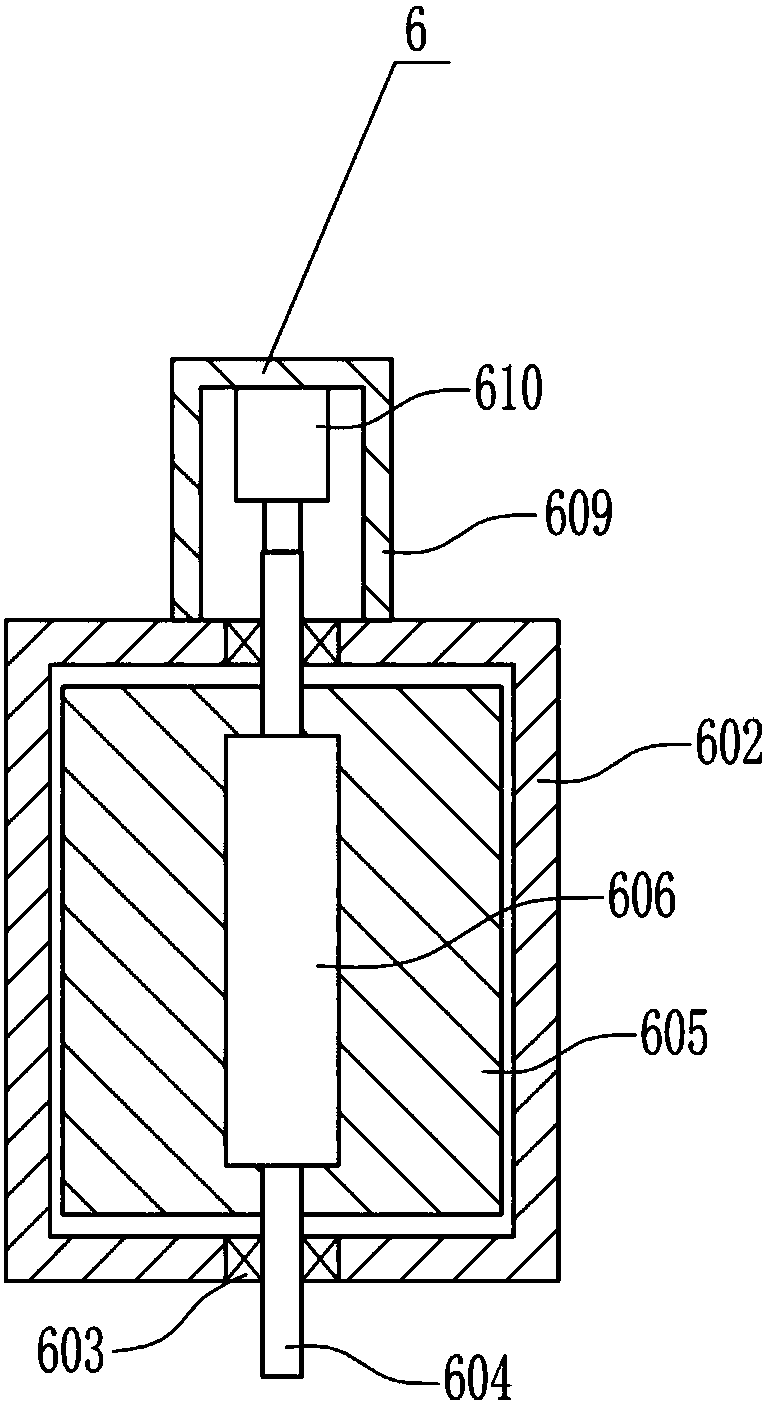

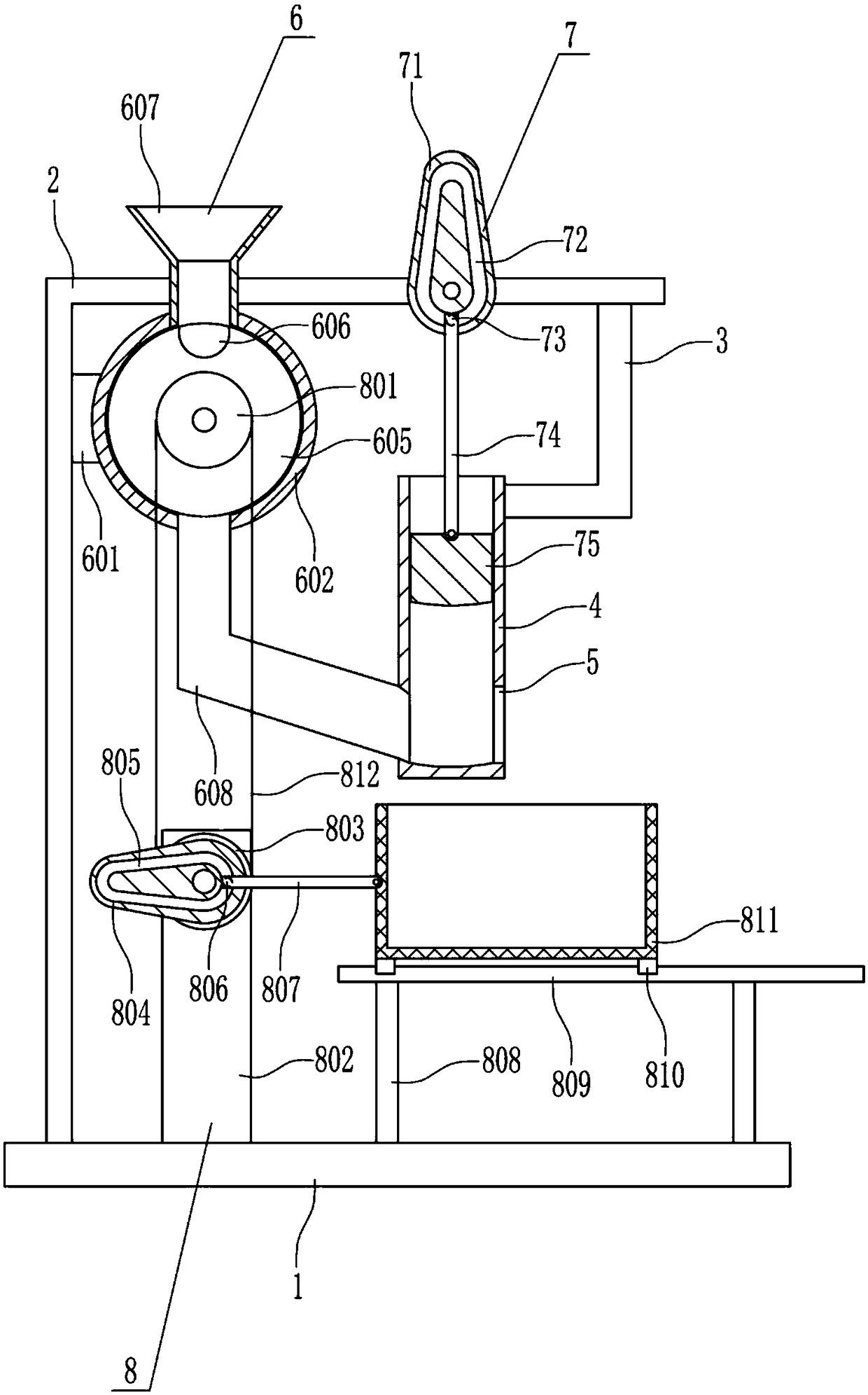

[0029] A kind of mechanical tung fruit crushing equipment, such as Figure 1-5 As shown, it includes bottom plate 1, 7-shaped plate 2, L-shaped rod 3, hollow sleeve 4, intermittent feeding device 6 and crushing device 7, and the left side of the top of bottom plate 1 is connected with 7-shaped plate 2 and 7-shaped plate 2 Intermittent feeding device 6 is installed on the upper part of the inner left side, and a crushing device 7 is installed on the upper part of the front side of the 7-type plate 2. An L-shaped rod 3 is connected to the right side of the inner top of the 7-type plate 2, and a hollow sleeve is connected to the left end of the L-shaped rod 3. The cylinder 4 and the crushing parts of the crushing device 7 are located in the hollow sleeve 4, and the discharge part of the intermittent feeding device 6 is connected and communicated with the lower left side of the hollow sleeve 4, and the lower right side of the hollow sleeve 4 has an opening 5.

Embodiment 2

[0031] A kind of mechanical tung fruit crushing equipment, such as Figure 1-5 As shown, it includes bottom plate 1, 7-shaped plate 2, L-shaped rod 3, hollow sleeve 4, intermittent feeding device 6 and crushing device 7, and the left side of the top of bottom plate 1 is connected with 7-shaped plate 2 and 7-shaped plate 2 Intermittent feeding device 6 is installed on the upper part of the inner left side, and a crushing device 7 is installed on the upper part of the front side of the 7-type plate 2. An L-shaped rod 3 is connected to the right side of the inner top of the 7-type plate 2, and a hollow sleeve is connected to the left end of the L-shaped rod 3. The cylinder 4 and the crushing parts of the crushing device 7 are located in the hollow sleeve 4, and the discharge part of the intermittent feeding device 6 is connected and communicated with the lower left side of the hollow sleeve 4, and the lower right side of the hollow sleeve 4 has an opening 5.

[0032]The intermitt...

Embodiment 3

[0034] A kind of mechanical tung fruit crushing equipment, such as Figure 1-5 As shown, it includes bottom plate 1, 7-shaped plate 2, L-shaped rod 3, hollow sleeve 4, intermittent feeding device 6 and crushing device 7, and the left side of the top of bottom plate 1 is connected with 7-shaped plate 2 and 7-shaped plate 2 Intermittent feeding device 6 is installed on the upper part of the inner left side, and a crushing device 7 is installed on the upper part of the front side of the 7-type plate 2. An L-shaped rod 3 is connected to the right side of the inner top of the 7-type plate 2, and a hollow sleeve is connected to the left end of the L-shaped rod 3. The cylinder 4 and the crushing parts of the crushing device 7 are located in the hollow sleeve 4, and the discharge part of the intermittent feeding device 6 is connected and communicated with the lower left side of the hollow sleeve 4, and the lower right side of the hollow sleeve 4 has an opening 5.

[0035] The intermit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com