Improved natural substance fermentation extraction device

A natural material and extraction device technology, applied in grain processing, etc., can solve problems such as inability to carry out efficient mixing, uneven material thickness, single mixing reverse, etc., to achieve the effect of increasing work convenience, simple structure, and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

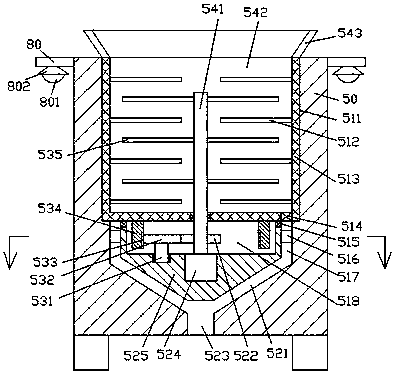

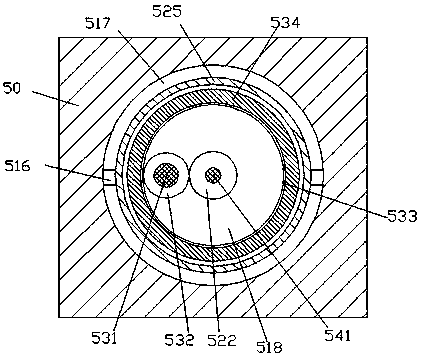

[0014] Combine below Figure 1-Figure 2 The present invention will be described in detail.

[0015] refer to Figure 1-Figure 2 , an improved natural material fermentation extraction device according to an embodiment of the present invention, comprising a processing frame body 50, a rotating chamber 511 is arranged in the top end surface of the processing frame body 50, and a stirring chamber is installed in the rotating chamber 511 for rotation. Crushing disk 513, the top end surface of the crushing disk 513 is provided with a crushing cavity 542, the inner surface of the crushing cavity 542 is fixed with a plurality of groups of outer crushing leaves 512, and the bottom of the rotating cavity 511 The processing frame body 50 is connected with an annular cavity 517, and the inner walls of the left and right sides of the annular cavity 517 are fixedly installed with bumps 516, and a driving seat 525 is fixedly installed between the bumps 516 between the left and right sides. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com